Construction waste sorting device and use method

A construction waste and sorting device technology, which is applied in the direction of using tools for cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc. problems, to improve the utilization rate and economy, improve the efficiency of magnetic separation, reduce the effect of scattered blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

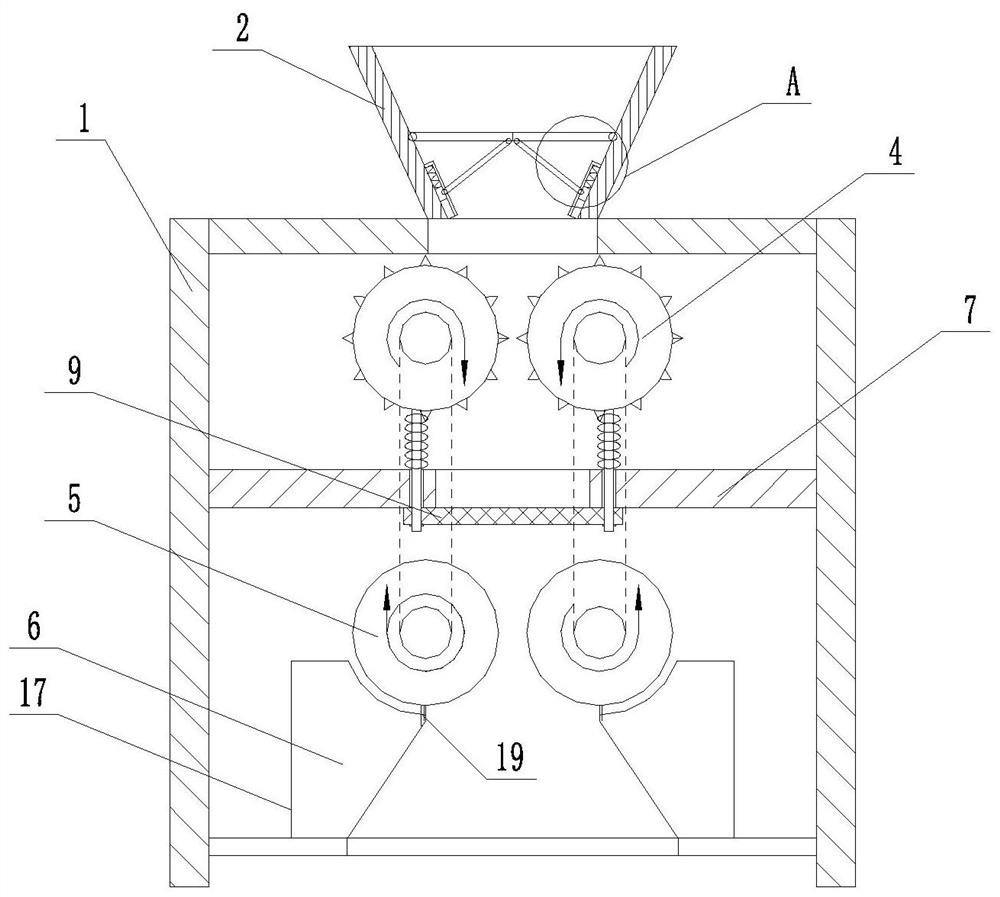

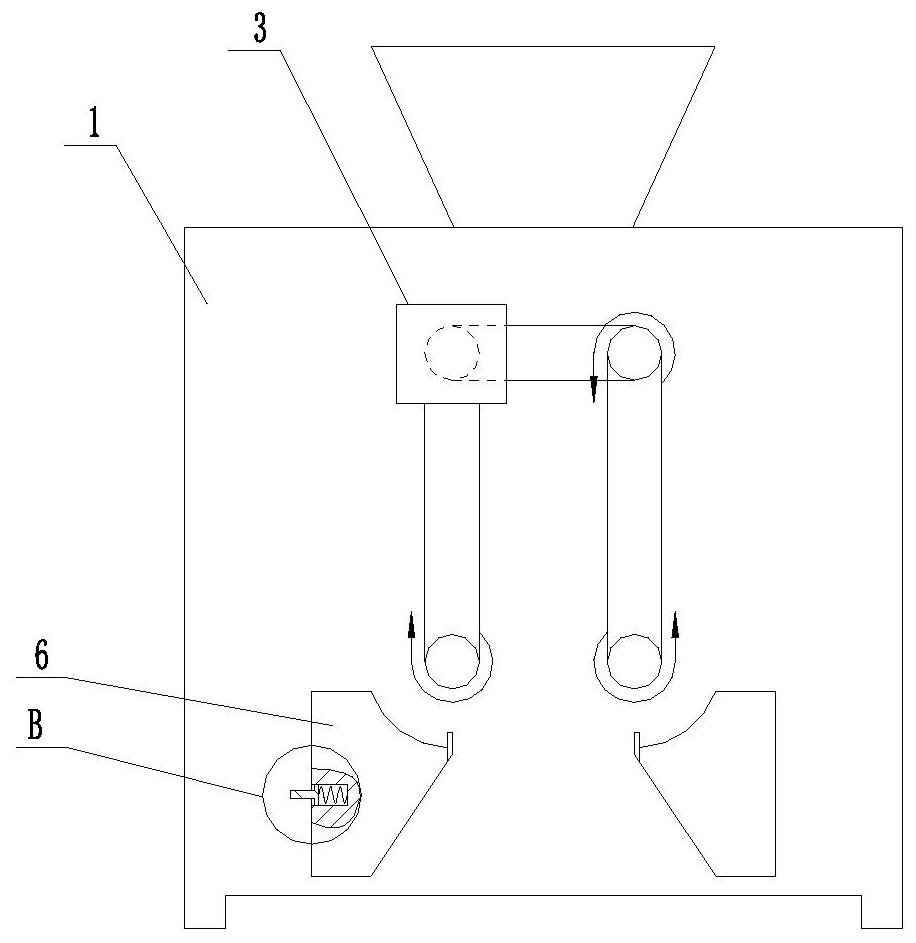

[0030] Such as figure 1 , image 3 , Figure 4 and Figure 6 As shown, a sorting device for construction waste includes a box body 1, a feed hopper 2 is fixedly arranged on the box body 1, and a crushing mechanism is provided inside the box body 1, and the crushing mechanism includes a drive motor 3 and two left and right side-by-side The crushing roller 4 and the driving motor 3 are fixedly installed outside the casing 1, the output shaft of the driving motor 3 is fixedly connected with one of the crushing rollers 4, and the two crushing rollers 4 are connected through a chain drive. The driving motor 3 drives the two crushing rollers 4 to crush the construction waste, so that the internal magnetic material can be exposed to facilitate resource recovery.

[0031] A magnetic separation mechanism is fixedly installed on the casing 1 below the crushing roller 4. The magnetic separation mechanism includes a magnetic separation cylinder 5 and a collection box 6. Two magnetic se...

Embodiment 2

[0034] Such as figure 1 and Figure 5 As shown, on the basis of Example 1, a further preferred solution is provided. A partition 7 is fixedly connected directly below the crushing roller 4. A blanking opening is provided in the middle of the partition 7. A movable rod runs through the partition 7 vertically. 8. The bottom of the movable rod 8 is fixedly connected with the filter plate 9 at the blanking port, the top of the movable plate is fixedly connected with the support plate 10, and the movable rod 8 between the support plate 10 and the partition 7 is sleeved There is a spring, and a cam 11 is fixedly connected to the crushing roller 4 , and the outer peripheral surface of the cam 11 is attached to the support plate 10 . The crushing roller 4 drives the cam 11 to rotate, so that the outer circumference of the cam 11 is pressed against the support plate 10, and at the same time the support plate 10 moves up under the action of the spring, thereby realizing the periodic mo...

Embodiment 3

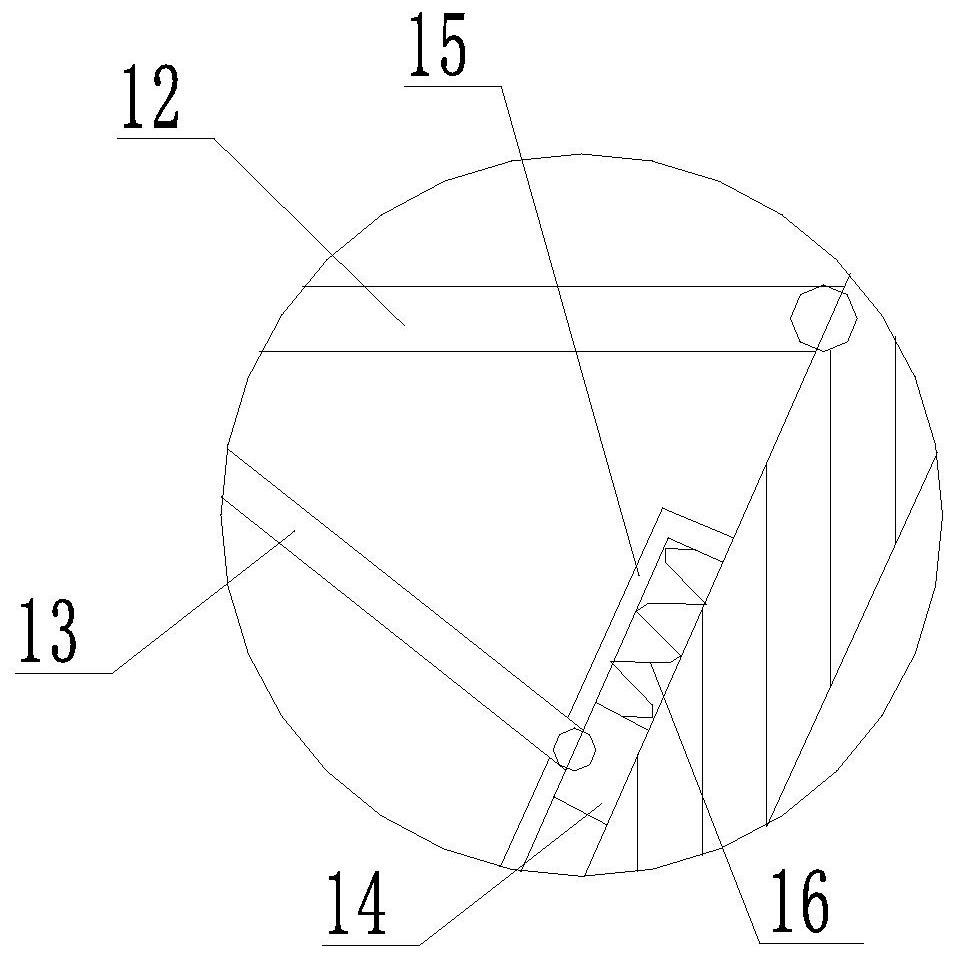

[0036] Such as figure 2As shown, on the basis of Embodiment 2, a further preferred solution is provided. The inner left and right sides of the feed hopper 2 are rotatably connected with a protective plate 12, and the middle part of the protective plate 12 is rotatably connected with a connecting rod 13, and the connecting rod 13 is far away from the protective plate. One end of the plate 12 is rotatably connected with a slide block 14, and the feed hopper 2 below the protective plate 12 is fixedly connected with a track 15 for the free movement of the slide block 14, and the track 15 is provided with a return spring 16 and is fixedly connected with the slide block 14 . To prevent the excessive pressure when the construction waste is crushed and cause damage to surrounding personnel, through the protective plate 12, connecting rod 13, slider 14, track 15 and return spring 16, after the construction waste enters the hopper, it will completely pass through Behind the protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com