Multi-stage crushing and dust-removing toner cartridge recycling and processing system

A technology for recycling and toner cartridges, applied in grain processing, plastic recycling, recycling technology and other directions, can solve the problems of low recovery rate, large dust on the disassembly site, insufficient disassembly of toner cartridges, etc., to avoid dust and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0037] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

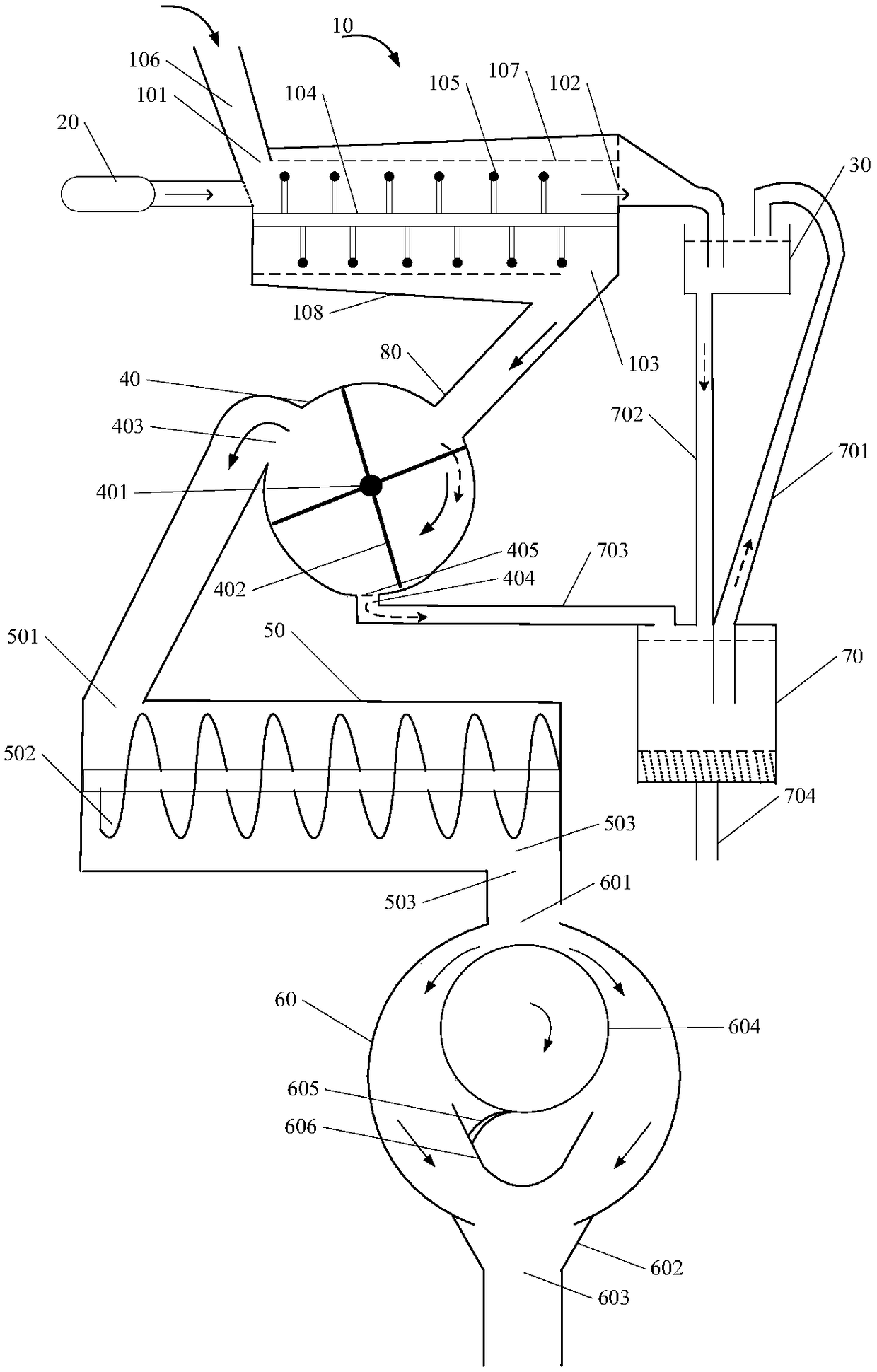

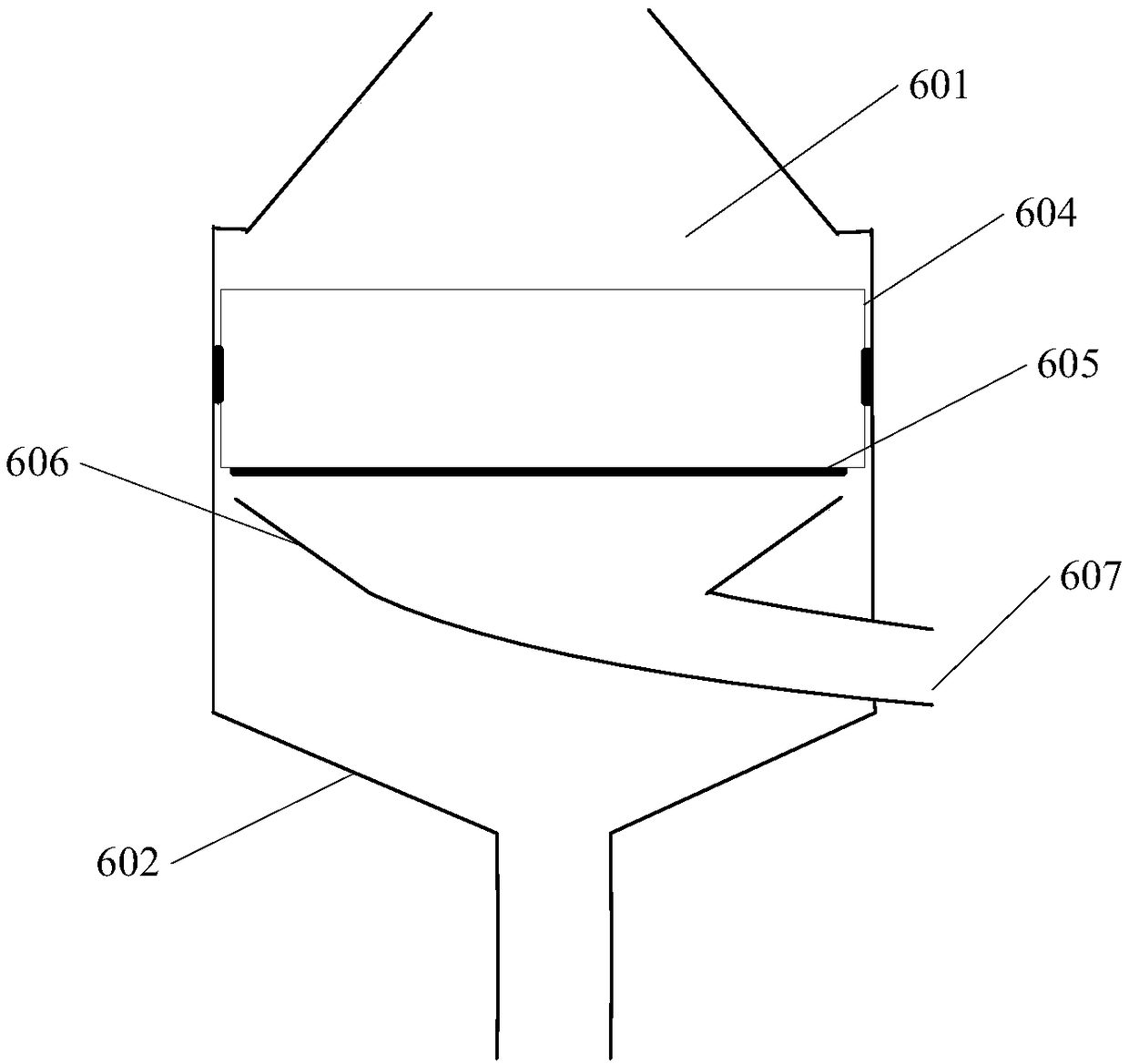

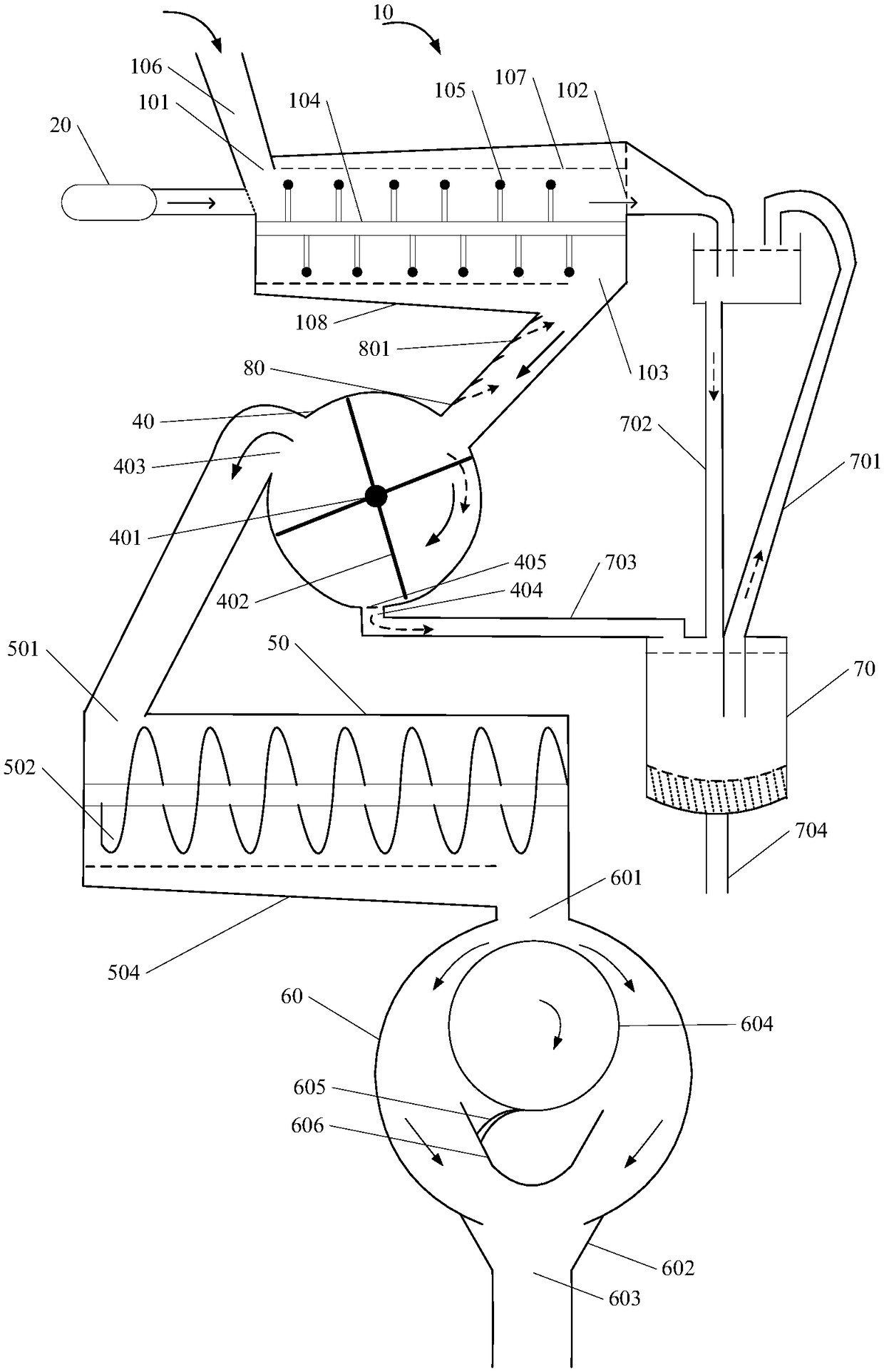

[0038] like figure 1 , 2 , Shown in 5, the present invention provides a kind of toner cartridge recovery treatment system of multi-stage crushing and dedusting, comprising:

[0039] The crushing bin 10 includes an inner cylinder 107 and an outer cylinder 108 nested in each other, wherein the inner cylinder is arranged horizontally, and the inner cylinder is horizontally arranged, and the cross section of the inner cylinder is circular, and the outer cylinder The cross-section is elliptical, and the diameter of the cross-section gradually increases from one end of the outer cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com