Magnetic separator for efficiently separating magnetic materials

A magnetic material and magnetic separator technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory separation effect between magnetic materials and non-magnetic materials, and achieve complete magnetic separation and magnetic separation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the protection content of the present invention is not limited thereto.

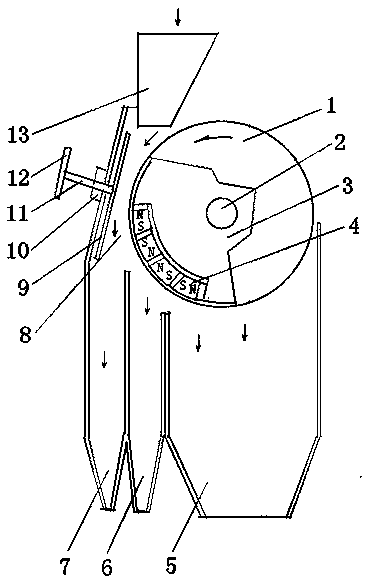

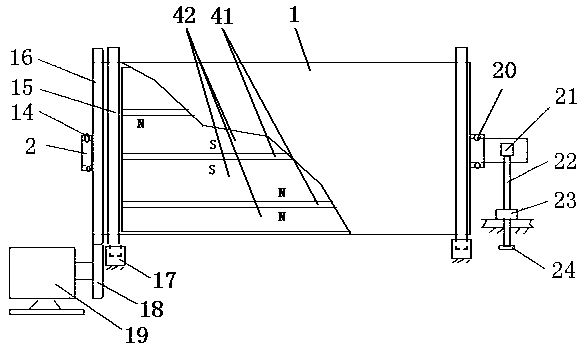

[0015] The magnetic separator for efficiently separating magnetic substances provided by the present invention comprises a casing, a rotating drum 1 arranged on the casing, a magnetic assembly 4 which is arranged in the rotating drum 1 and does not rotate with the rotating drum 1, is arranged on the casing and The feed port located above the rotating drum 1 and the discharge port located below the rotating drum 1, wherein: the magnetic assembly 4 includes a fixed roller 3, and the axial magnetic strips 41 arranged at intervals on the roller surface of the fixed roller 3 are arranged on the A permanent magnet 42 between two axial magnetic guide strips 41, and the magnetic poles of the permanent magnets 42 are arranged in the same pole on both sides of the axial magnetic guide strips 41, that is, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com