Belt type roller magnetic separator

A magnetic separator and roller technology, applied in the field of magnetic separators, can solve the problems of wasting limited resources, low magnetic separation efficiency, and large power consumption, and achieve high magnetic separation efficiency, improved magnetic separation efficiency, and large conveying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

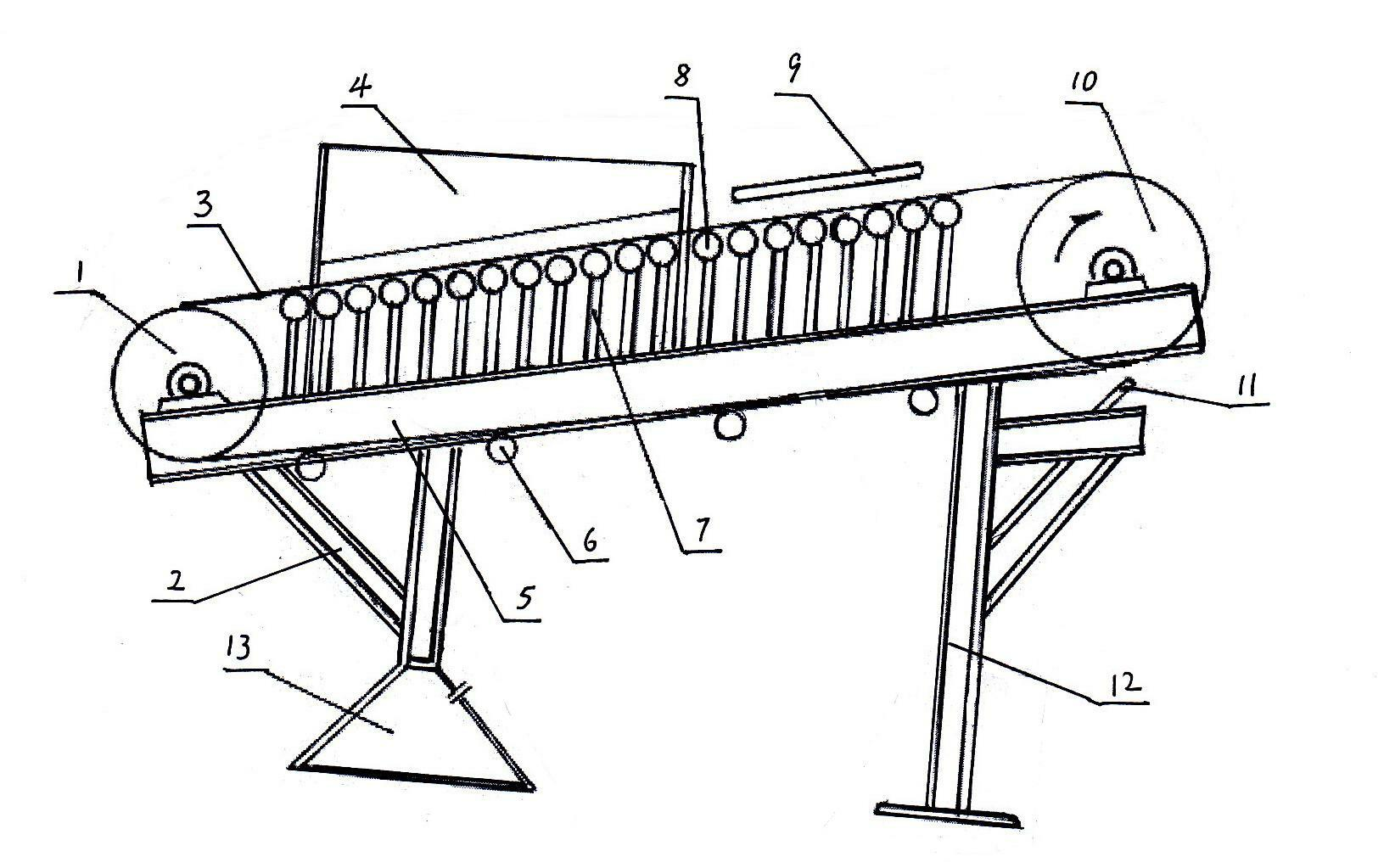

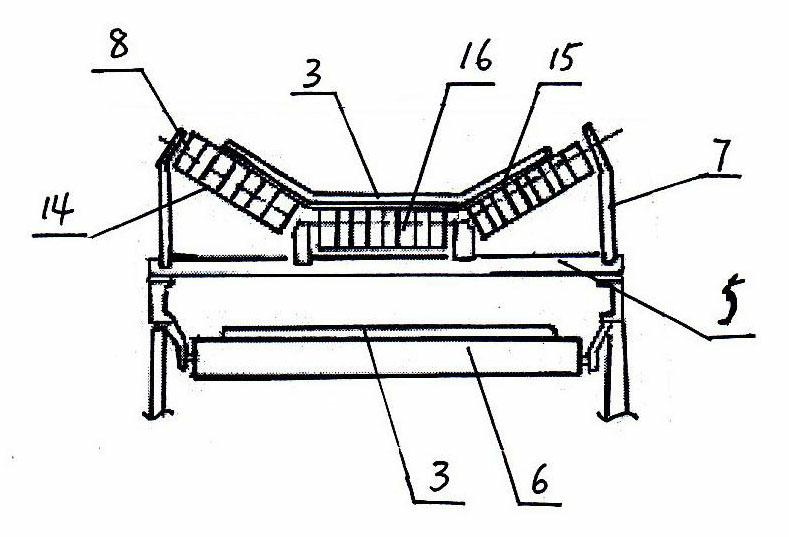

[0021] A belt-type roller magnetic separator, including a reversing drum 1, a left frame 2, a conveying belt 3, a rain step slurry dispersing screen 4, a belt conveying bracket 5, a conveying belt lower roller 6, and an upper washer 9 , the electric drum 10 and the right bracket 12, the conveyor belt 3 is wound on the reversing drum 1 and the electric drum 10, the left frame 2 and the right bracket 12 are respectively fixed under the left and right ends of the belt conveyor bracket 5, and the rain step slurry dispersion screen 4 and the upper washer 9 are respectively placed on the left end and the right end above the conveyor belt 3, and several groove-shaped high-strength magnet roller devices 8 are installed below the upper conveyor belt 3, and the high-strength magnet roller devices 8 are passed through Magnet support frame 7 is installed on the top of belt conveying support 5, idler roller 14 is formed on three separated conveyer belts, and permanent magnet 16 is housed in...

Embodiment 2

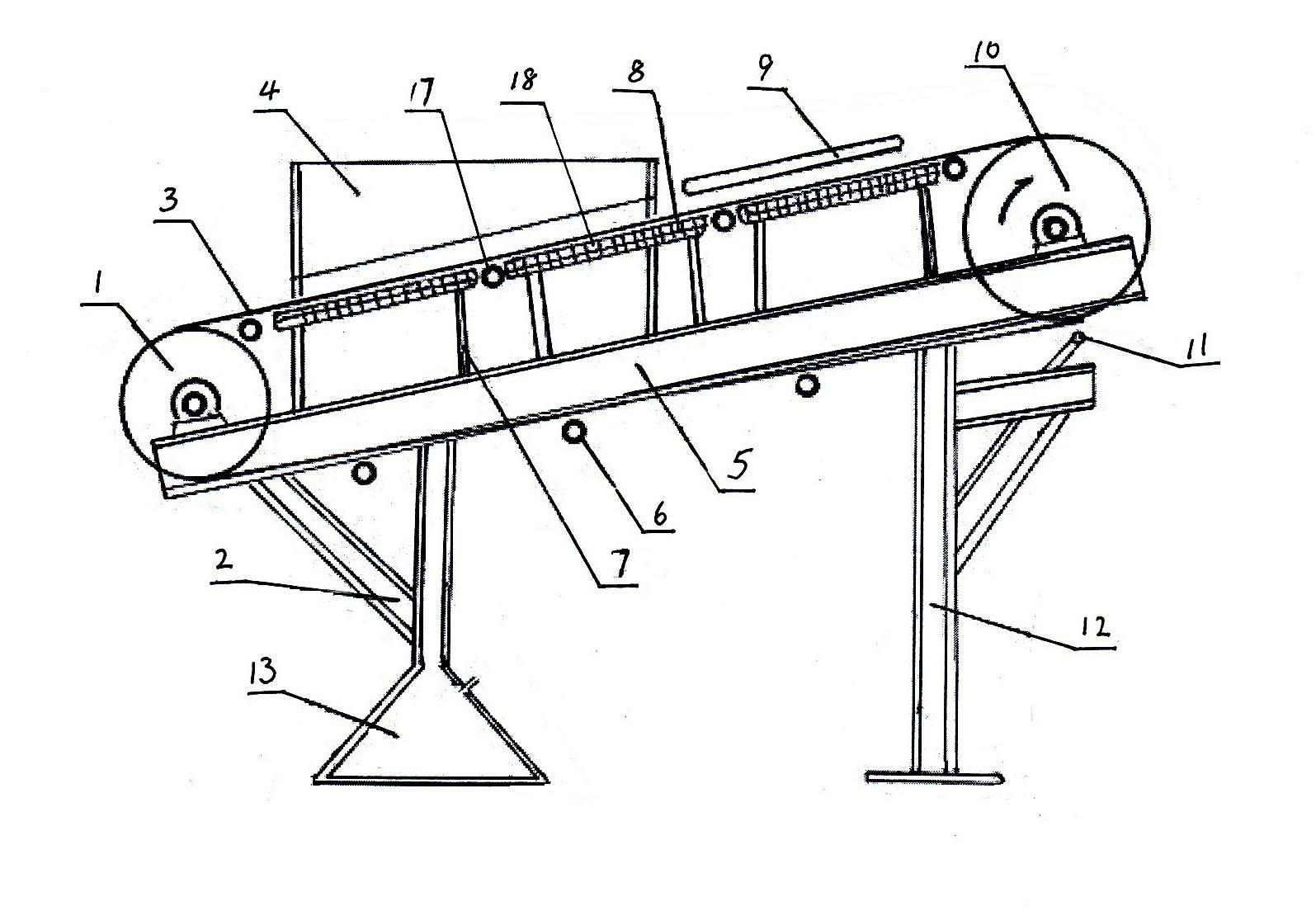

[0027] The structure of embodiment 2 is basically the same as embodiment 1, the difference is:

[0028] The high-strength magnet idler device 8 is made up of a grooved idler 17 and a grooved permanent magnet plate 18 on separate conveying belts, and a grooved permanent magnet is placed between two adjacent conveying belt grooved idlers 17. Magnet plate 18, groove-shaped permanent magnet plate 18 is installed on the top of belt conveying support 5 by magnet support frame 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com