An upflow activated carbon filter

An activated carbon filter and activated carbon technology, applied in the direction of adsorption water/sewage treatment, etc., can solve the problems of large-scale development of a single pool, few large-scale application examples, and difficulty in uniform water distribution, etc., to achieve compact structure and small footprint , the effect of uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

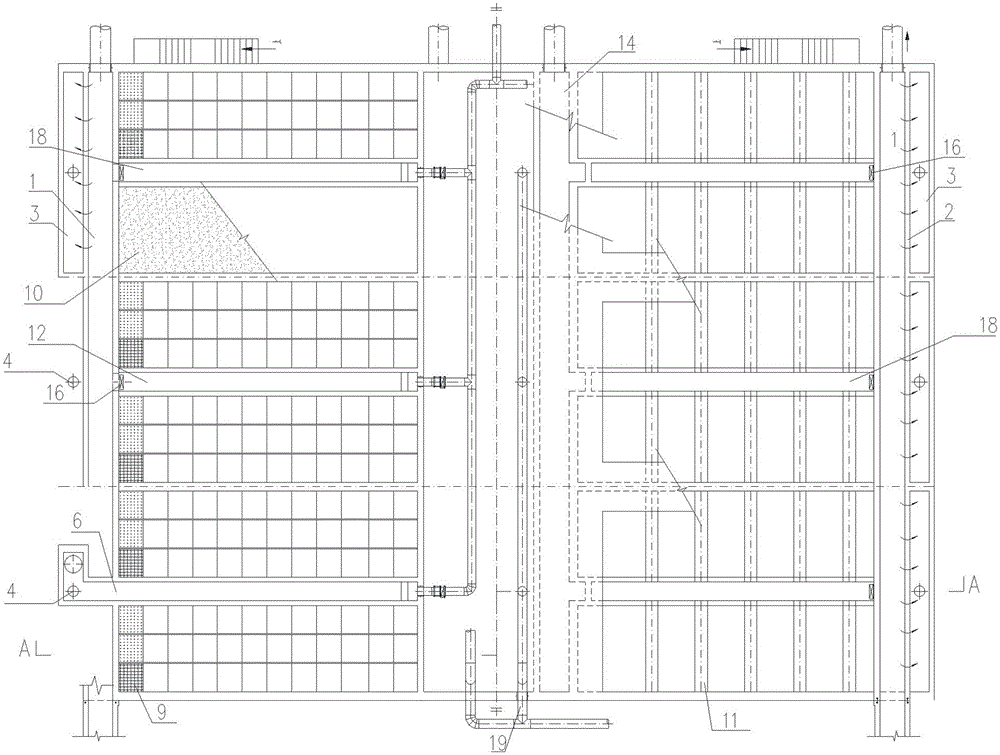

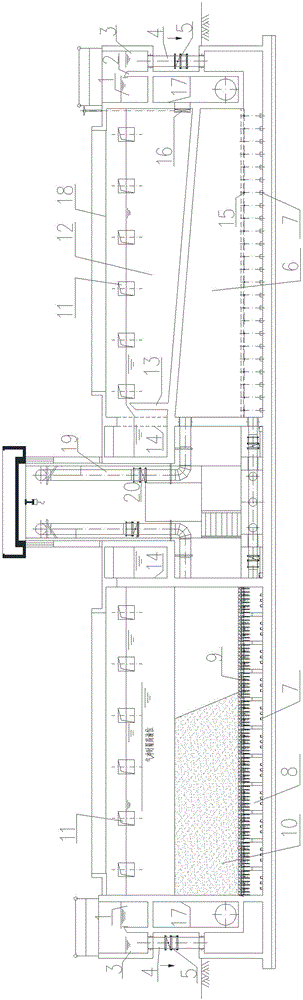

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0025] Such as figure 2 Shown, a kind of upflow activated carbon filter comprises a double-layer central channel 18 and an activated carbon filter layer 10; the double-layer central channel 18 is positioned at the center of the upward-flow activated carbon filter, and the double-layer central channel 18 includes the lower floor inlet channel 6 And the upper floor outlet channel 12, the bottom of the lower floor inlet channel 6 sidewalls is provided with distribution water holes 7, the activated carbon filter layer 10 is distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com