Patents

Literature

98results about How to "Reduce pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

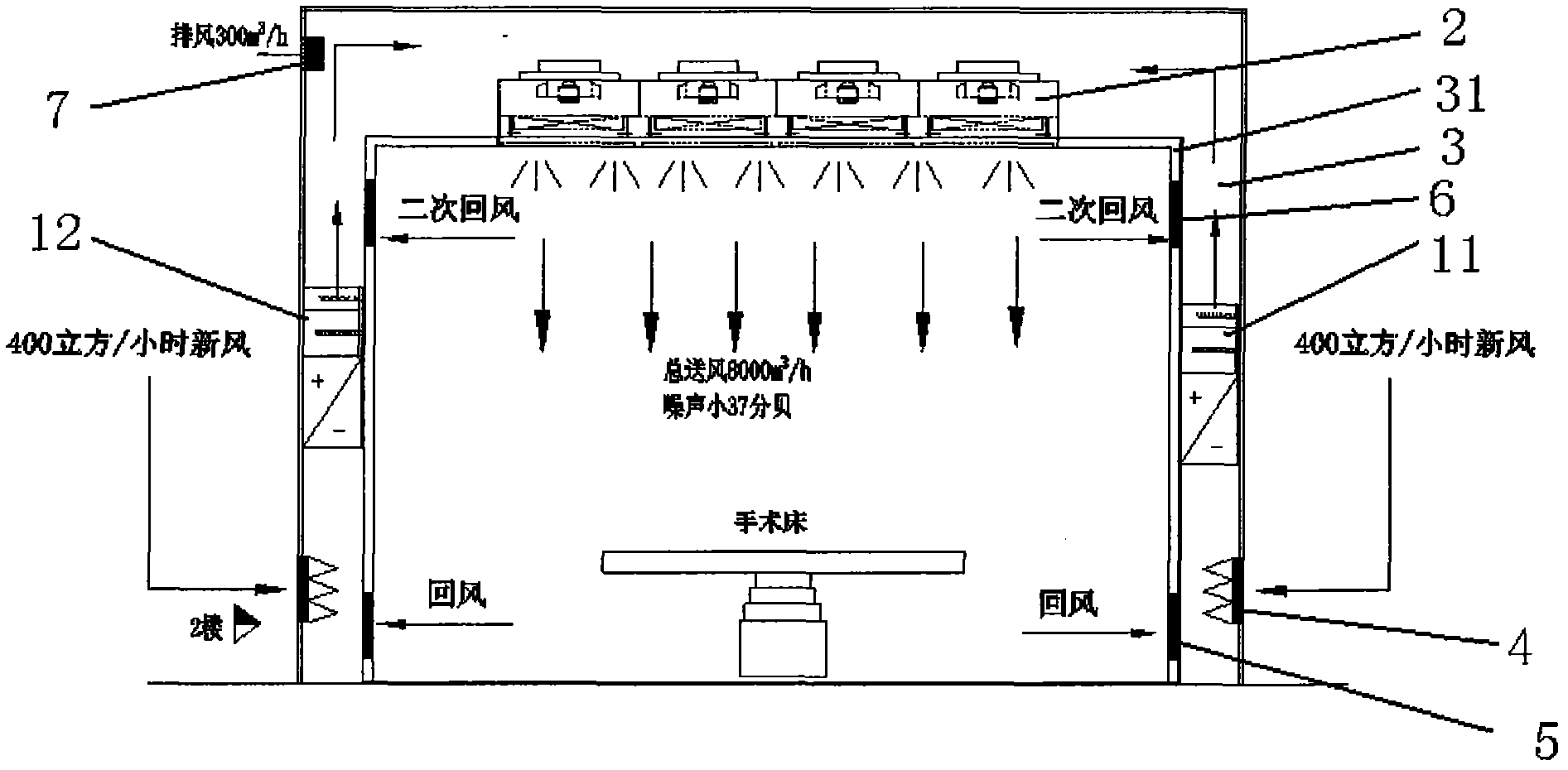

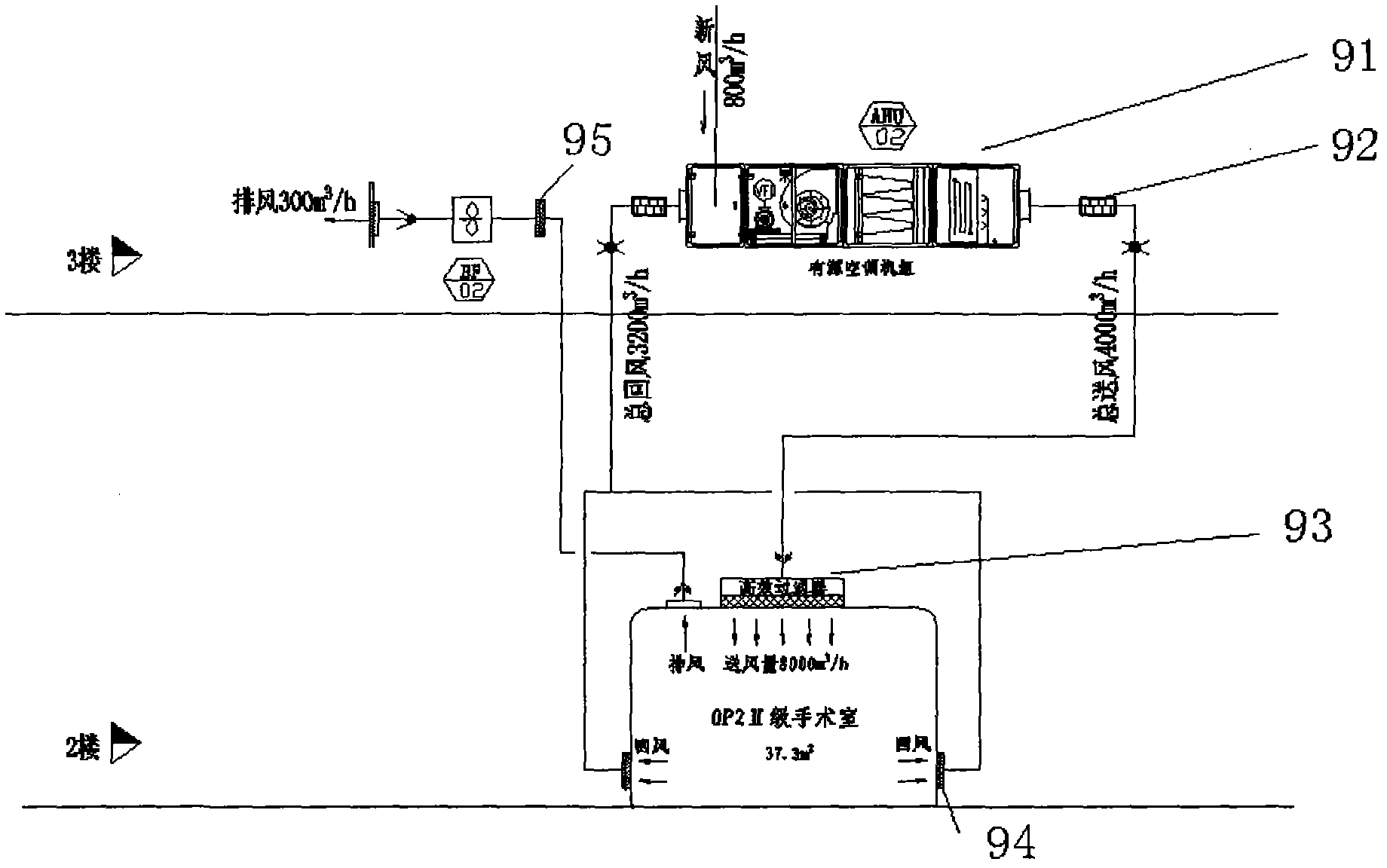

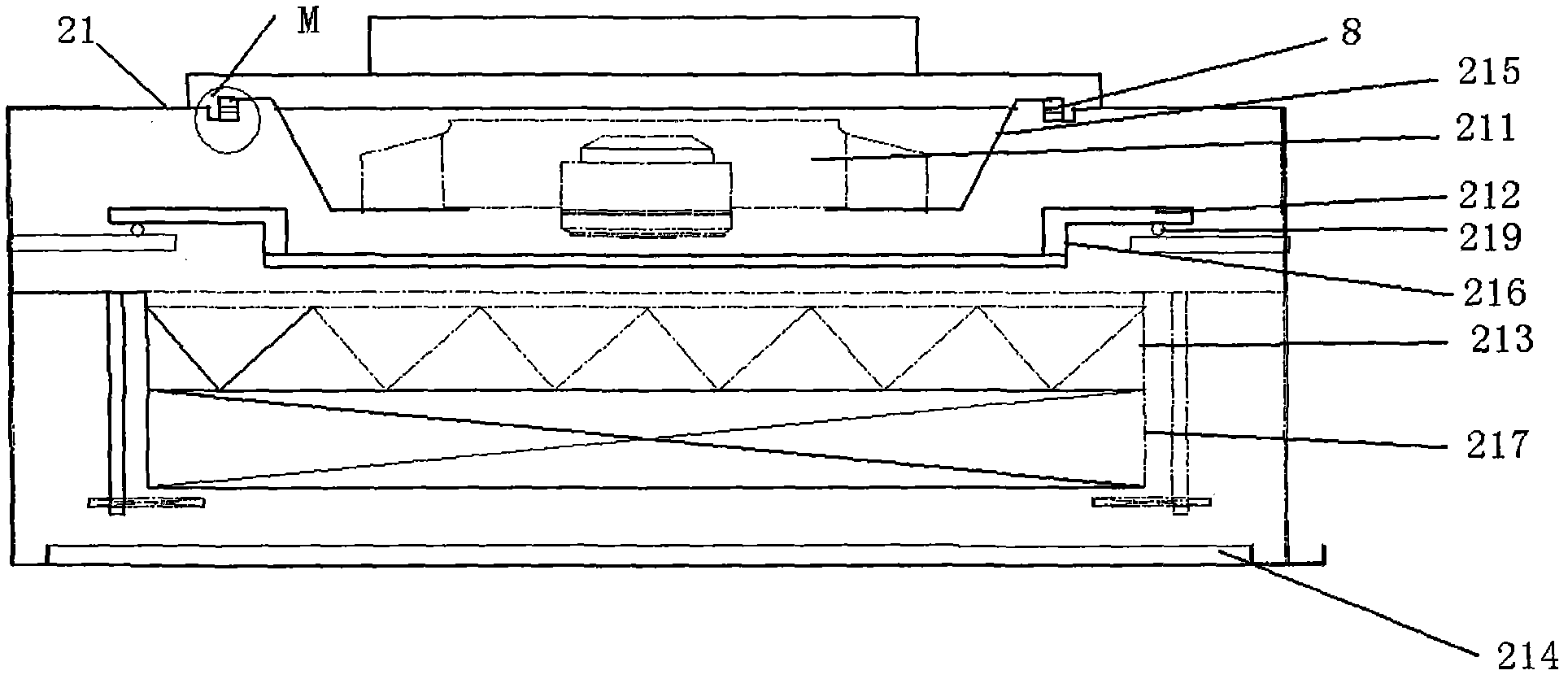

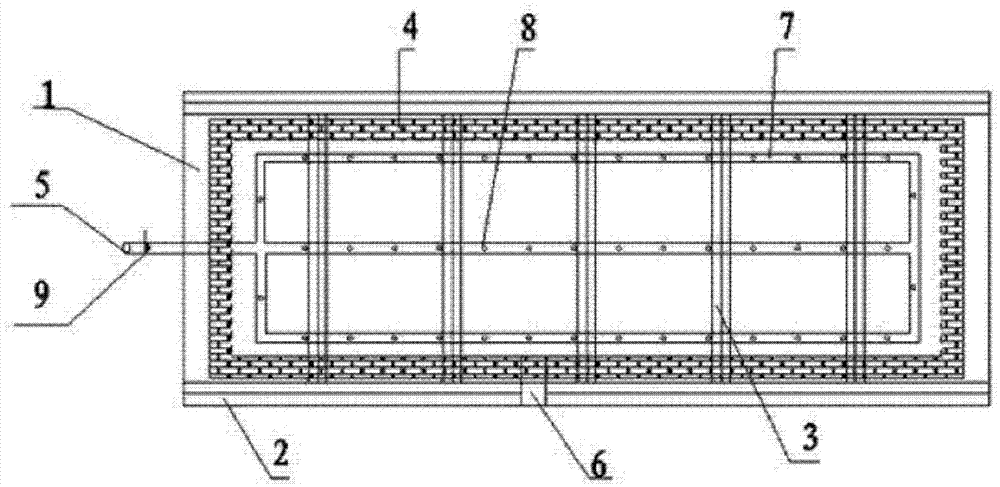

Energy-saving operating room air treatment system and clean operating room

ActiveCN102635907ASimple structureReduce residual pressureLighting and heating apparatusNoise suppressionDouble wallEngineering

The invention relates to an energy-saving operating room air treatment system and a clean operating room. The energy-saving operating room air treatment system comprises an air conditioning unit and a sound-eliminating direct-current fan unit. The air conditioning unit and the sound-eliminating direct-current fan unit are arranged in a double-wall of an operating room, the air conditioning unit is a constant-temperature and constant-humidity direct expansion air conditioning unit, the sound-eliminating direct-current fan unit comprises a shell; a fan, a sound eliminator, a middle efficiency filter and an airflow-diffusing orifice plate are arranged sequentially in the shell from top to bottom; the fan is fixed at the top of the shell through a fan semi-suspending support, the sound eliminator is fixed below the fan through a sound eliminator semi-suspending support, and the airflow-diffusing orifice plate is arranged at the bottom of the shell. The air treatment system is a pipeline-free system, which is simple in structure, convenience in assembly, energy-saving, lowered in noise and low in cost, so that construction process is simplified, time of the entire construction is shortened greatly, assembly is simple and convenient, and labour cost is reduced.

Owner:丽兹控股有限公司

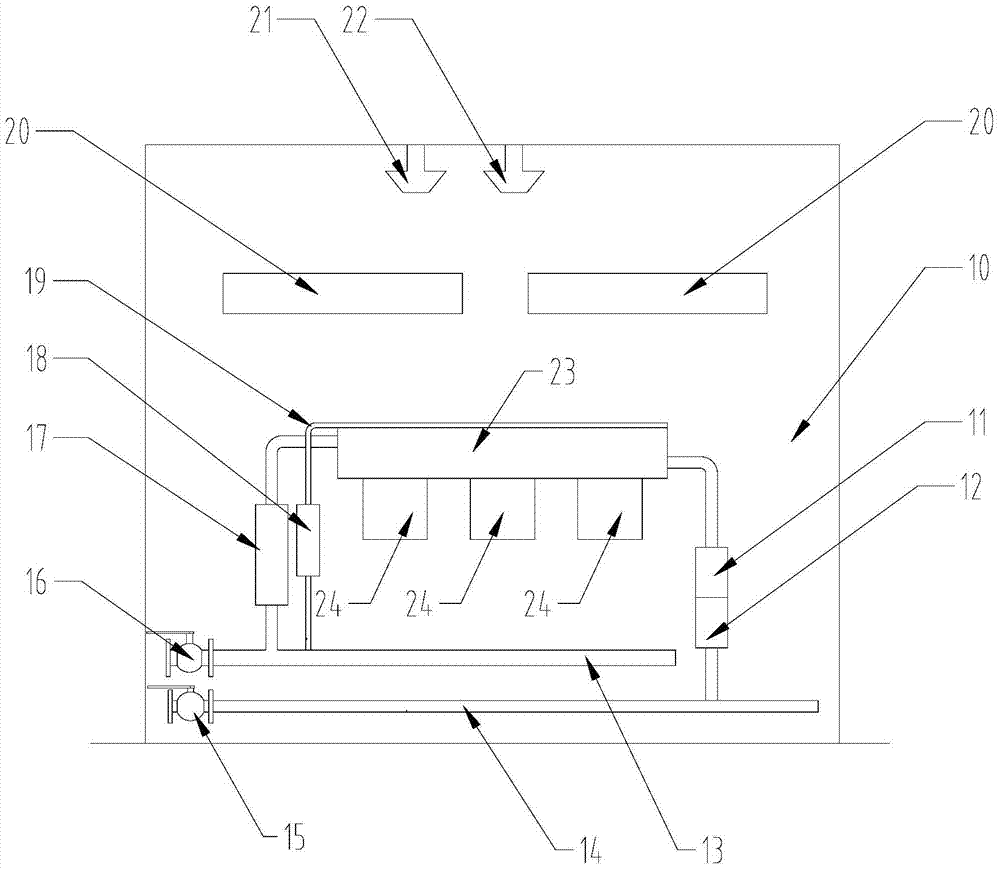

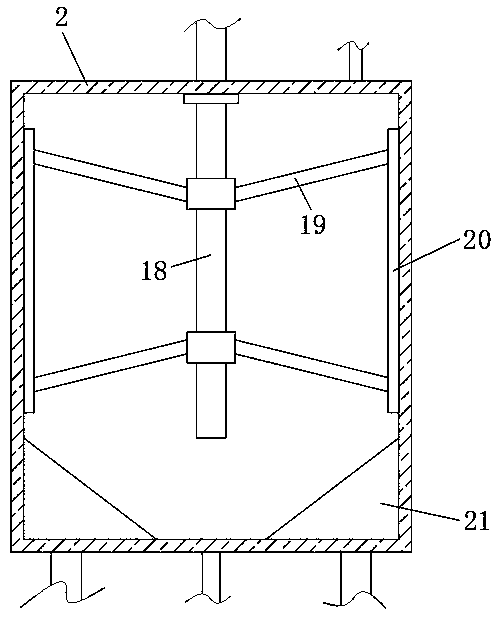

Precast concrete component curing forming device

InactiveCN105437361AImprove qualityDiffusion fastCeramic shaping apparatusEngineeringPrecast concrete

The invention discloses a precast concrete component curing forming device which comprises a curing kiln, a steam pipe, a drain pipe and a radiator, wherein the steam pipe, the drain pipe and the radiator are mounted in the curing kiln; the steam pipe is connected with the inlet of the radiator; the drain pipe is connected with the outlet of the radiator; a humidifying pipe is mounted in the curing kiln and connected with the steam pipe; and a steam hole is formed in the humidifying pipe. According to the precast concrete component curing forming device, the heat exchange rate is increased, the temperature of the curing kiln rises quickly, the temperature and humidity in the curing are even, and the quality of a precast concrete component is improved.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

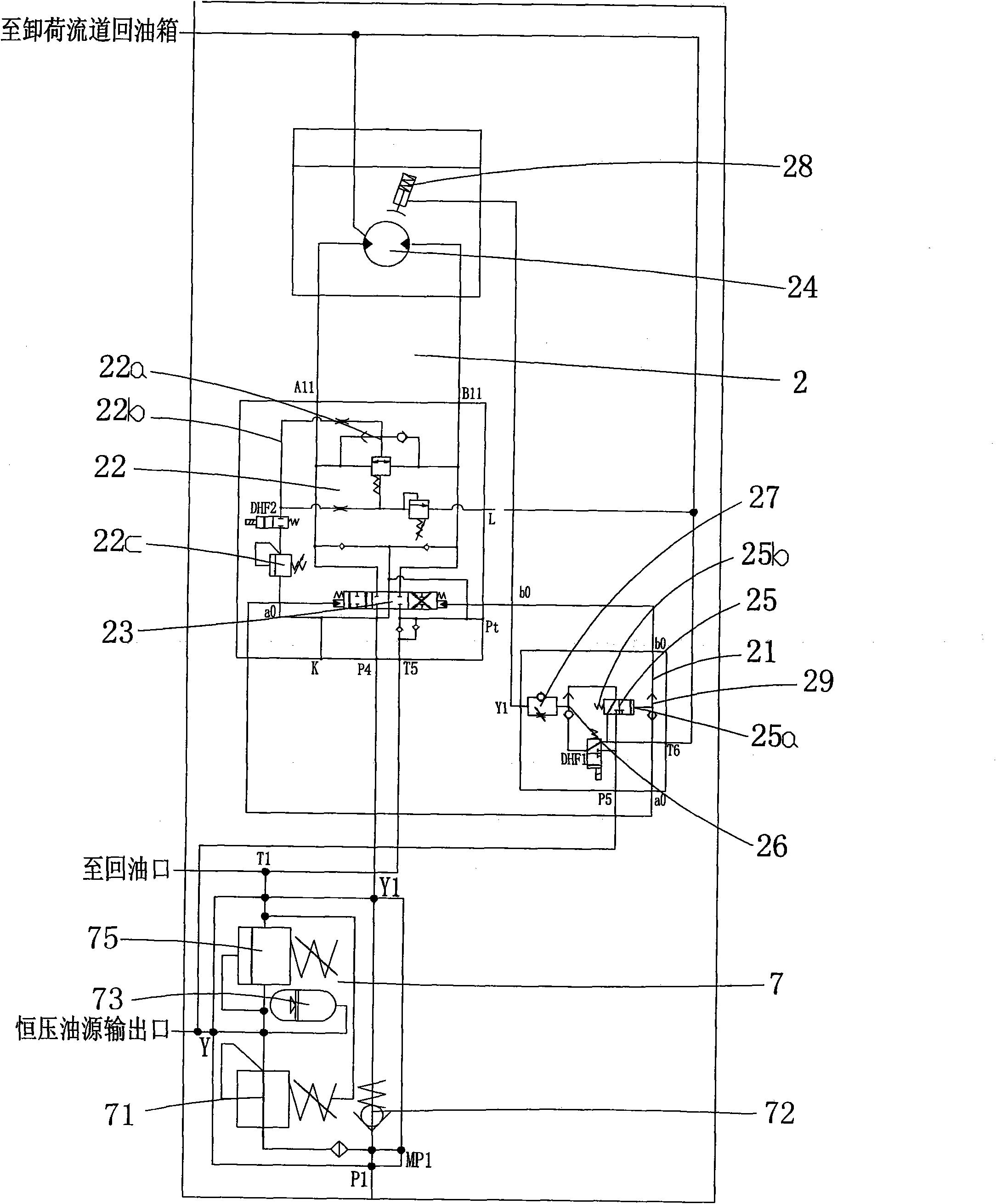

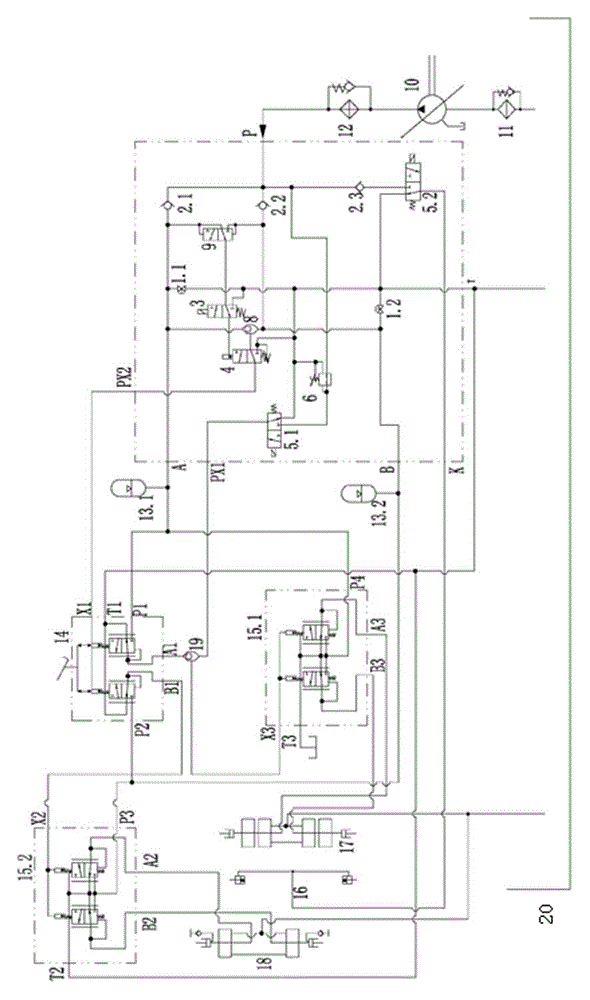

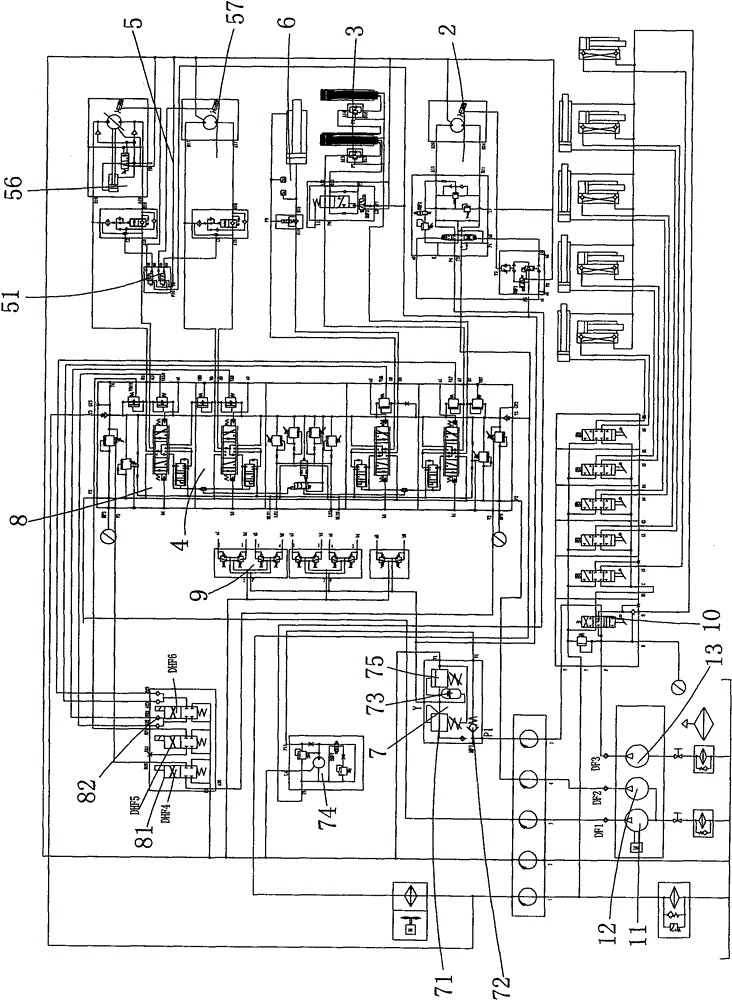

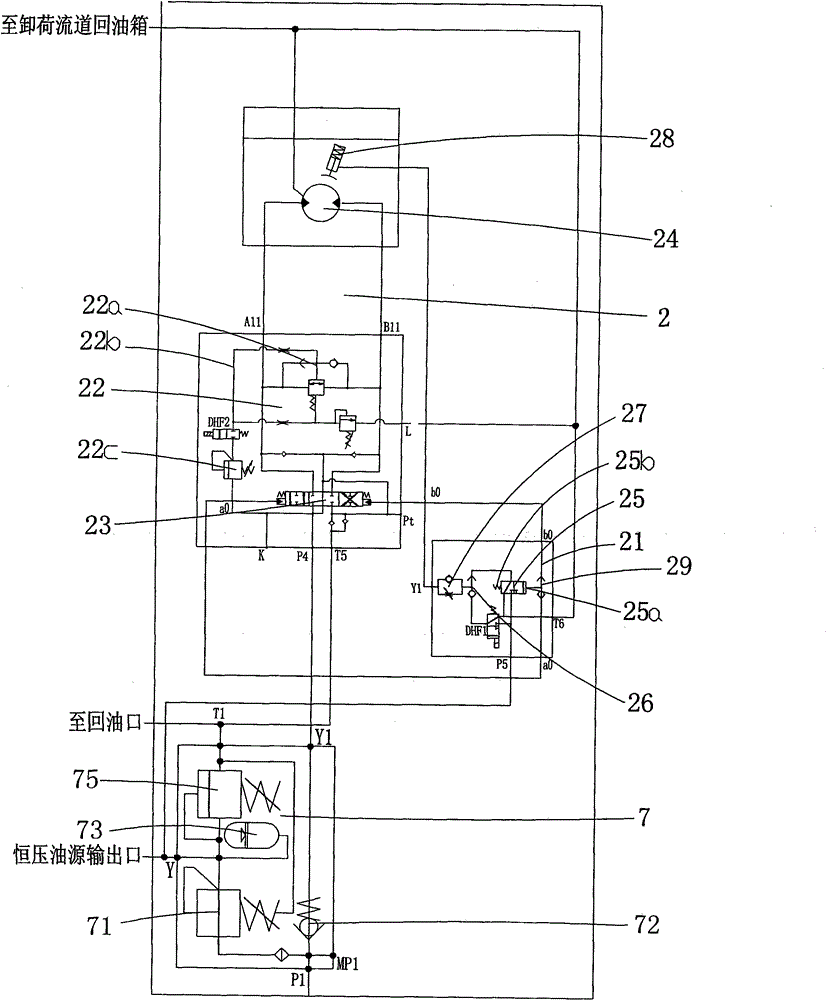

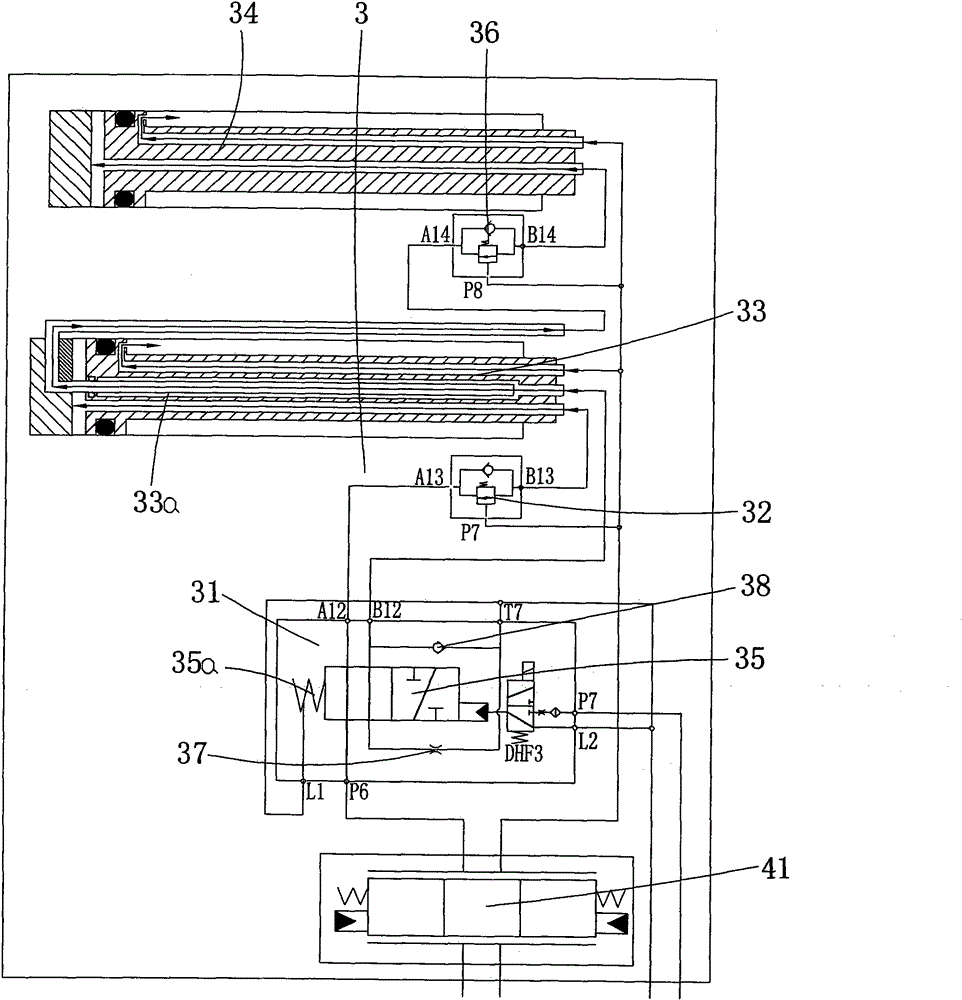

Hydraulic operation triple pump hydraulic system

ActiveCN101863421AReduce pipelineEliminate pressure shocksLoad-engaging elementsControl mannerControl valves

The invention relates to a hydraulic operation triple pump hydraulic system, which comprises a first oil pump, a second oil pump, a third oil pump, a rotary hydraulic system, a hoisting arm extension and retraction system, a safety unload hydraulic system, a lifting hydraulic system, a hoisting arm amplitude variation hydraulic system, a pressure reduction pilot oil source valve group and a control valve group, wherein the starting and closing characteristics of a rotary braking device, a main hoisting braking device and a sub hoisting braking device adopt the constant-pressure oil source control mode without additional external force operation, and the control on the braking devices can be intelligently and automatically realized according to the operation of each action. The invention realizes the fast-opening slow-closing control mode on a rotary structure and the slow-opening fast-closing control mode on main and sub hosting mechanisms according to different starting and closing characteristics of each mechanism, and effectively eliminates the pressure impact on the system. A flow distribution valve adopts the flow distribution mode irrelevant with a load, so slow action or noaction of executing mechanisms with high load pressure caused by pressure interference among all executing mechanisms can be effectively prevented. Each element in the whole vehicle system has high integration and modularization, and the maintenance is convenient.

Owner:卢宇

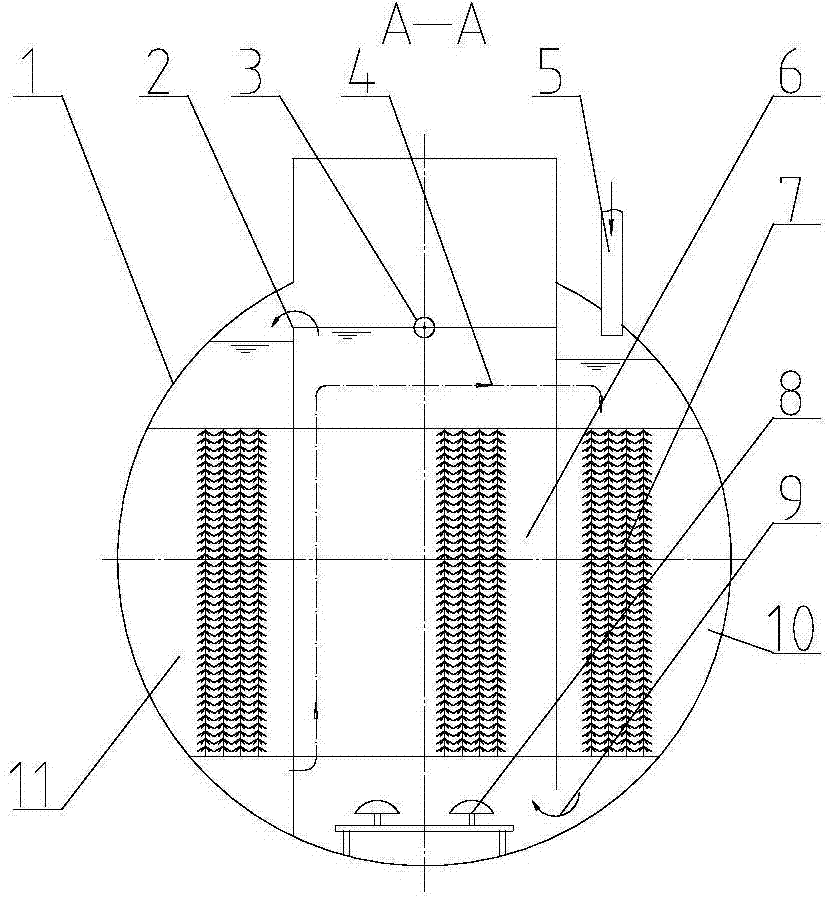

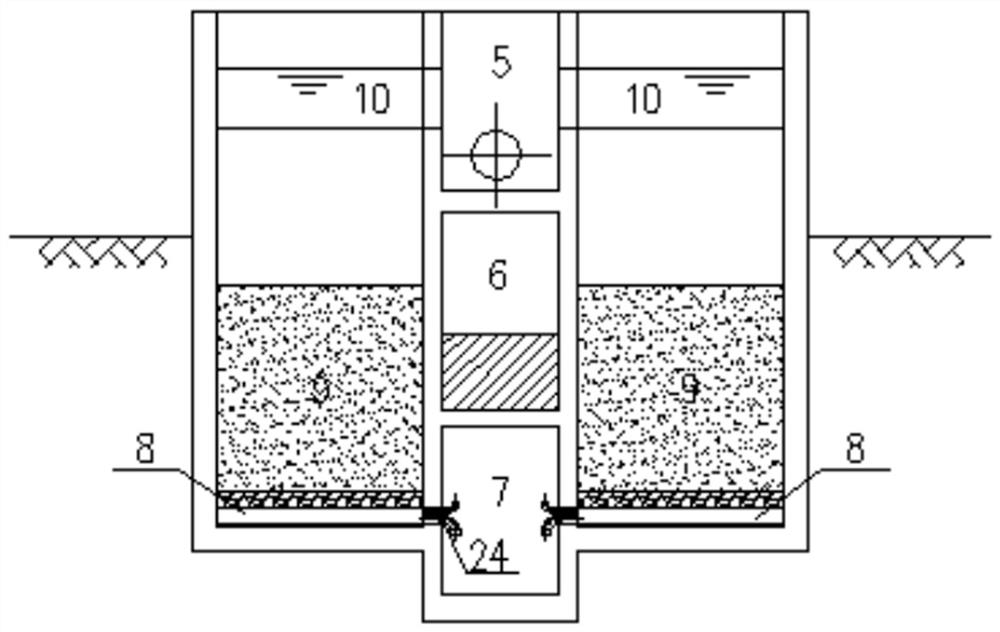

Integrated deep domestic sewage treatment facility and sewage treatment method thereof

ActiveCN103936157ASufficient hypoxiaFully anaerobic biochemical processTreatment with aerobic and anaerobic processesBiochemical engineeringOxygen

The invention discloses an integrated deep domestic sewage treatment facility which comprises a tank body, and an anoxic biochemical region, an aerobic biochemical region and an anaerobic biochemical region which are respectively distributed on the left, in the middle and on the right of the cross section of the tank body, wherein the anaerobic biochemical region and the aerobic biochemical region are communicated with each other only through the bottoms; the top liquid level of the aerobic biochemical region is higher than the top liquid level of the anoxic biochemical region; the top of the aerobic biochemical region is provided with a water outlet pipe extending into the aerobic biochemical region, and an overflow weir communicated with the anoxic biochemical region; the upper part liquid level of the anoxic biochemical region is higher than the upper part liquid level of the anaerobic biochemical region; the bottom of the anoxic biochemical region is communicated with the upper part of the anaerobic biochemical region through a gravity pipeline; the tank body is provided with a water inlet pipe communicated with the anaerobic biochemical region; the bottom of the aerobic biochemical region is provided with an aerator; the top of the aerobic biochemical region is provided with a biochemical water outlet and a precipitation tank water inlet pipe which are communicated to a precipitation tank; the precipitation tank is communicated with a sand filter tank through a sand filtration lifting water pump mechanism; and a back flush dynamic drift sand filter is arranged in the sand filter tank. The invention also discloses a sewage treatment method using the facility.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

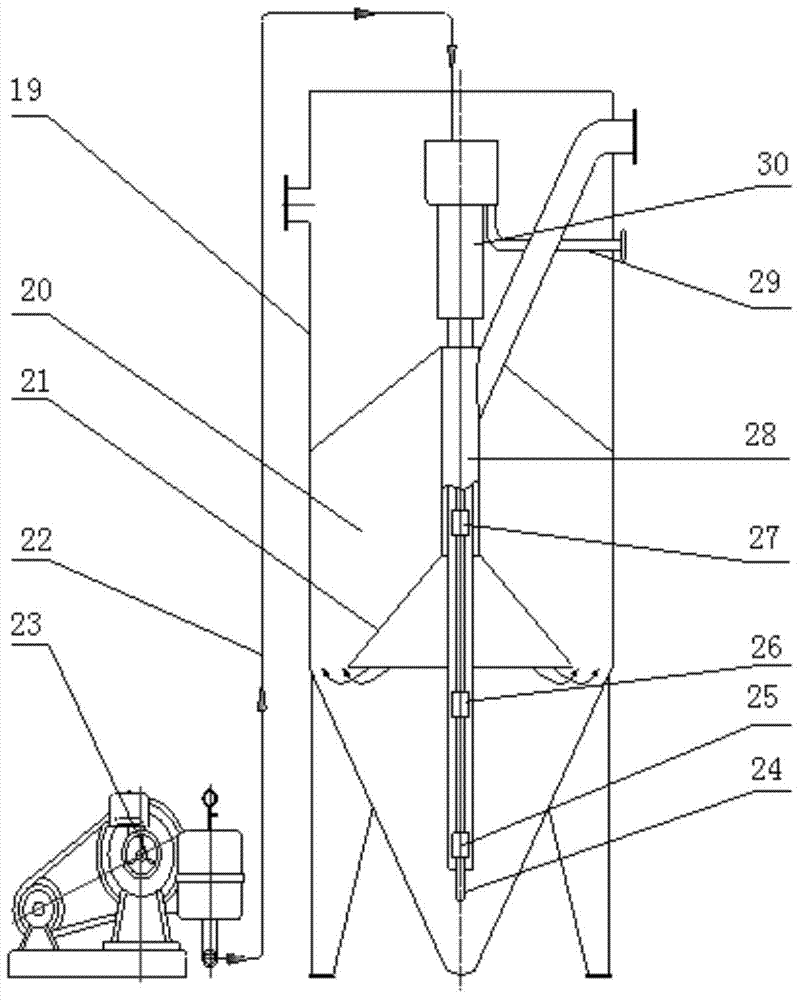

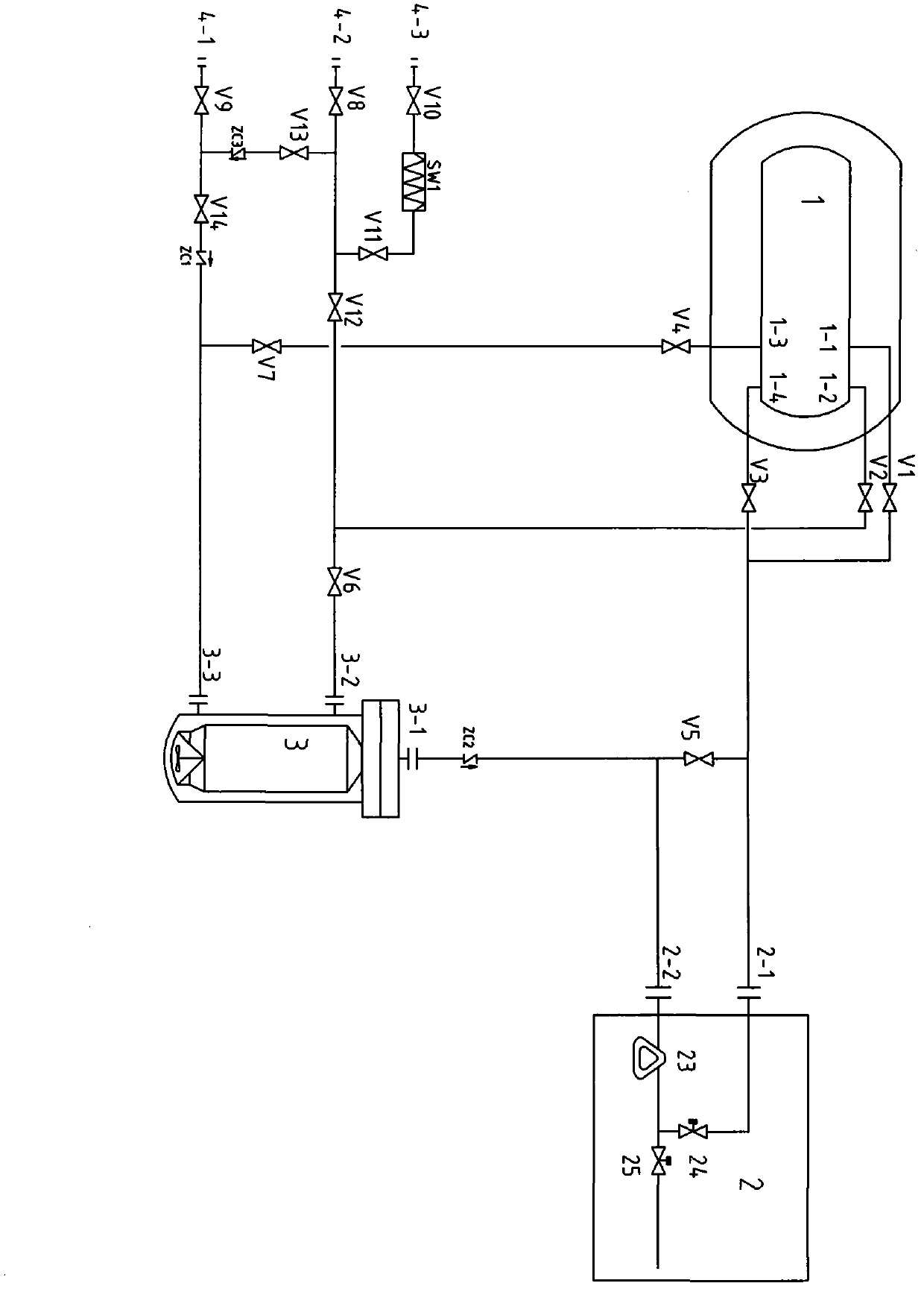

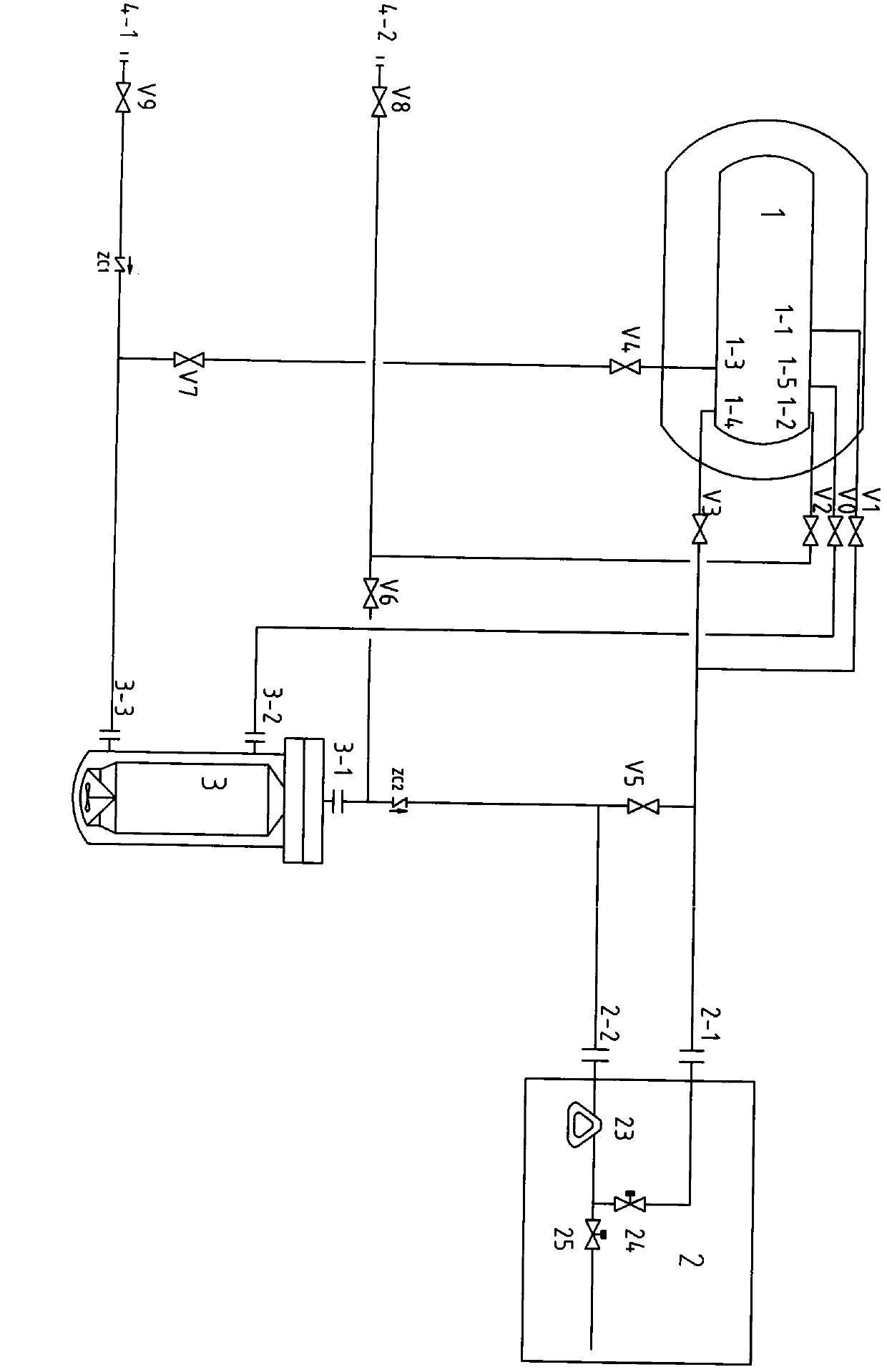

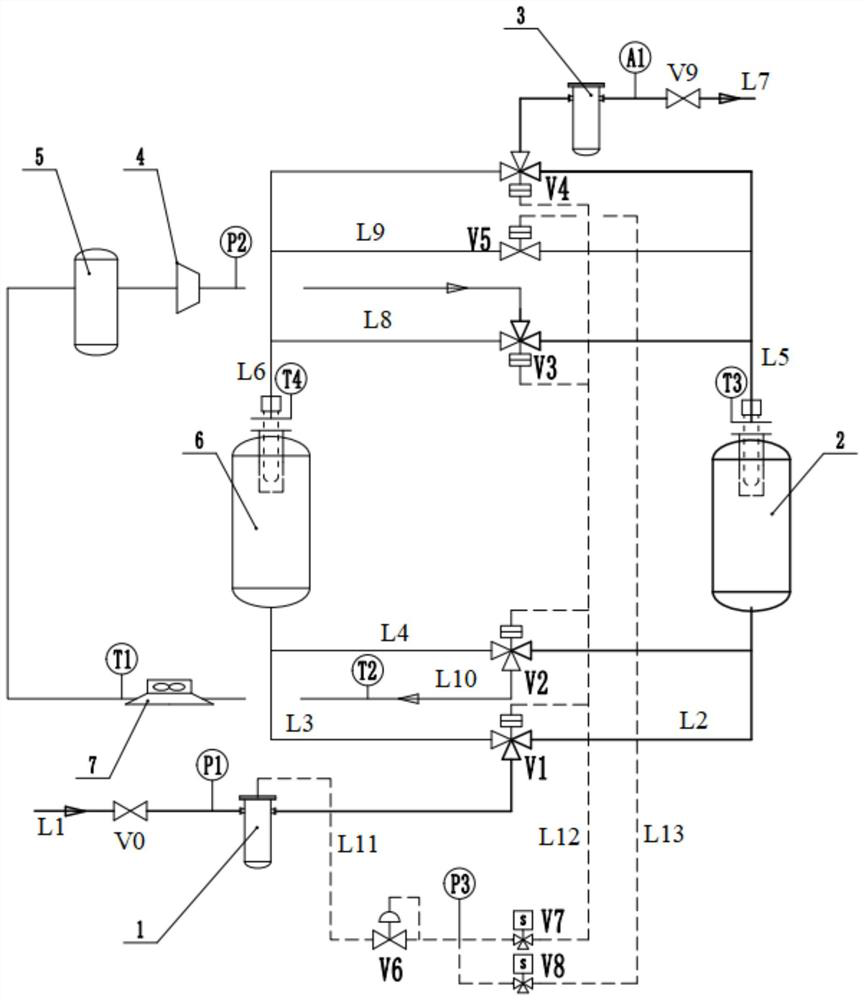

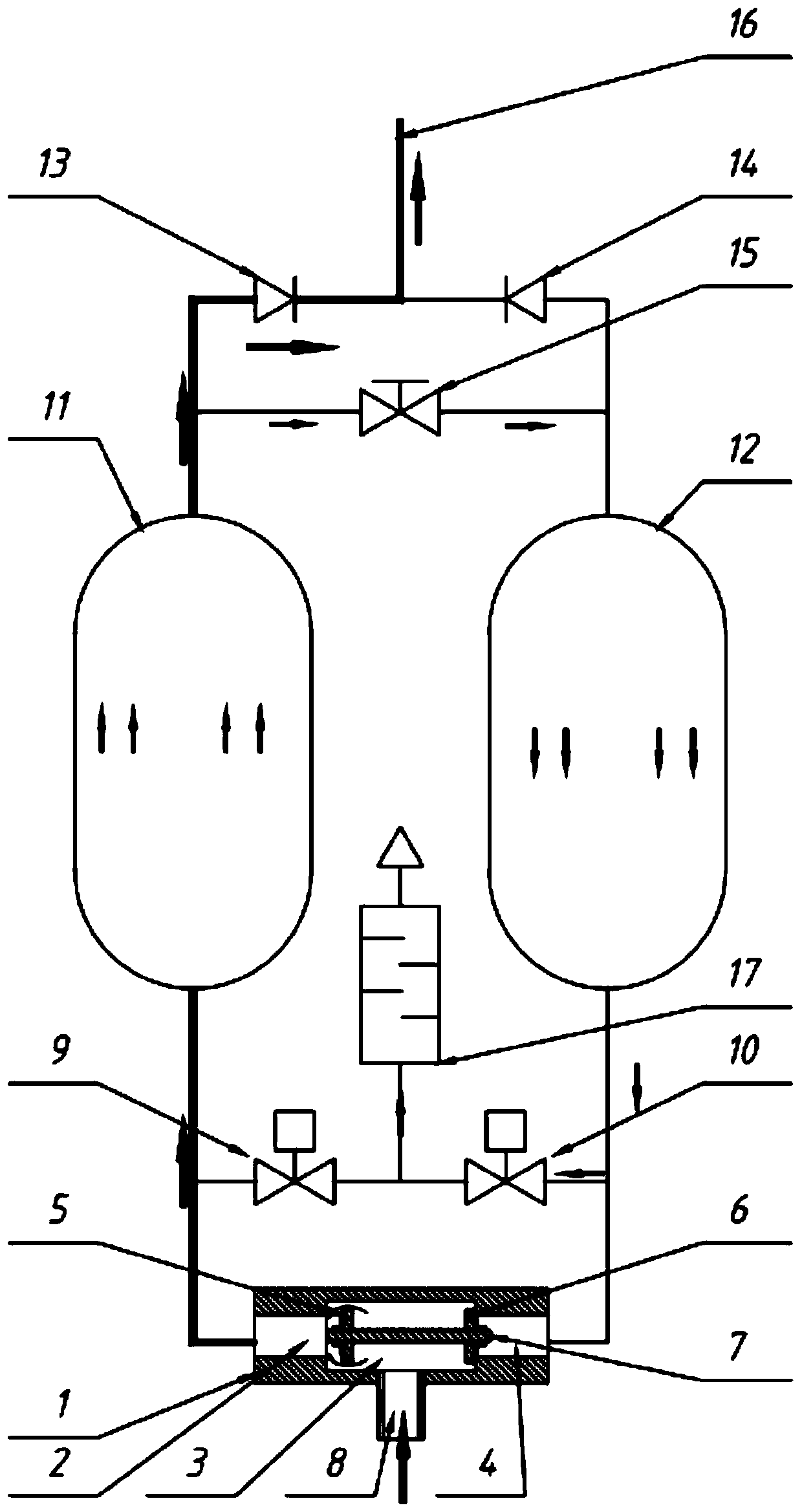

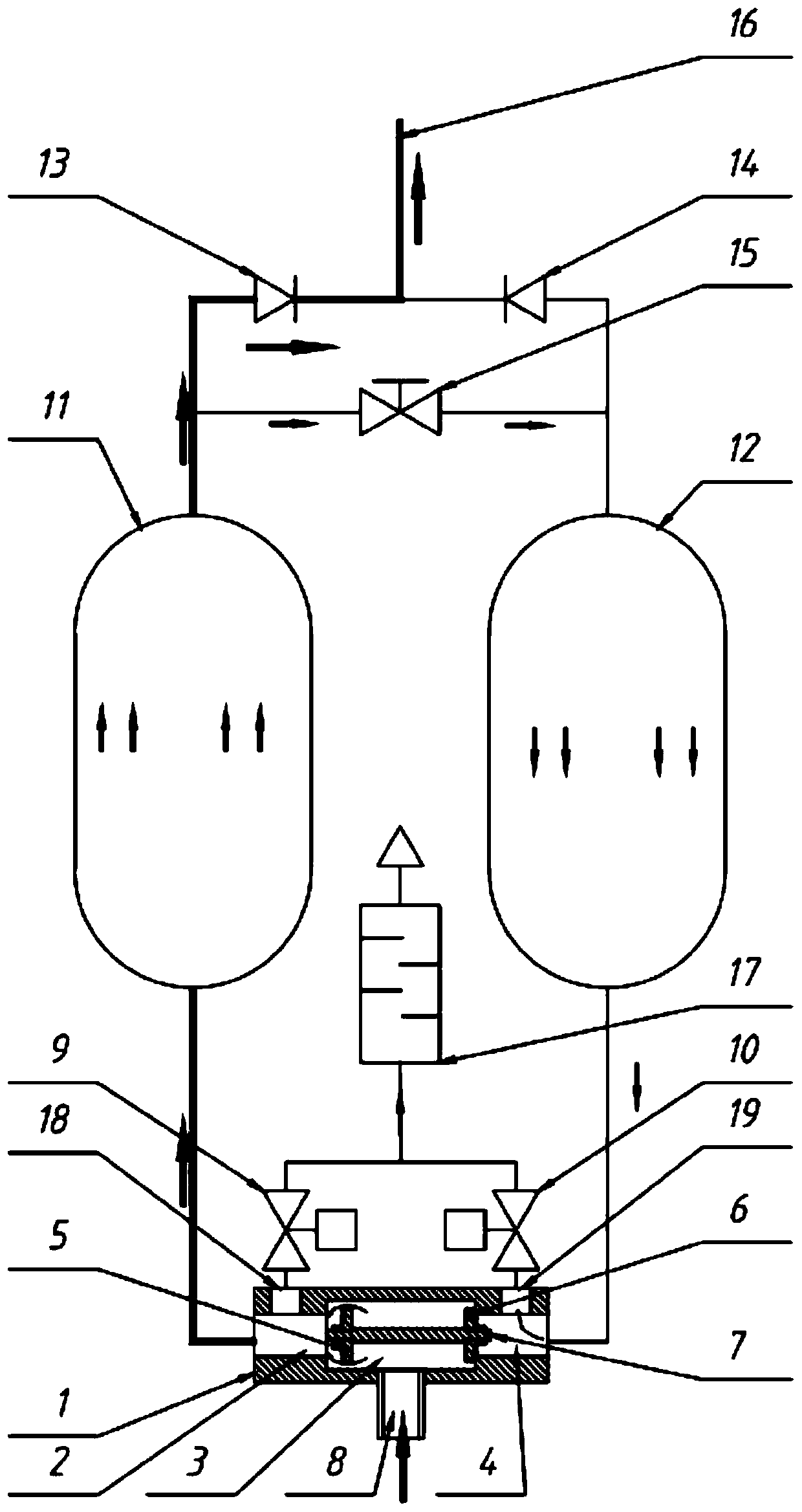

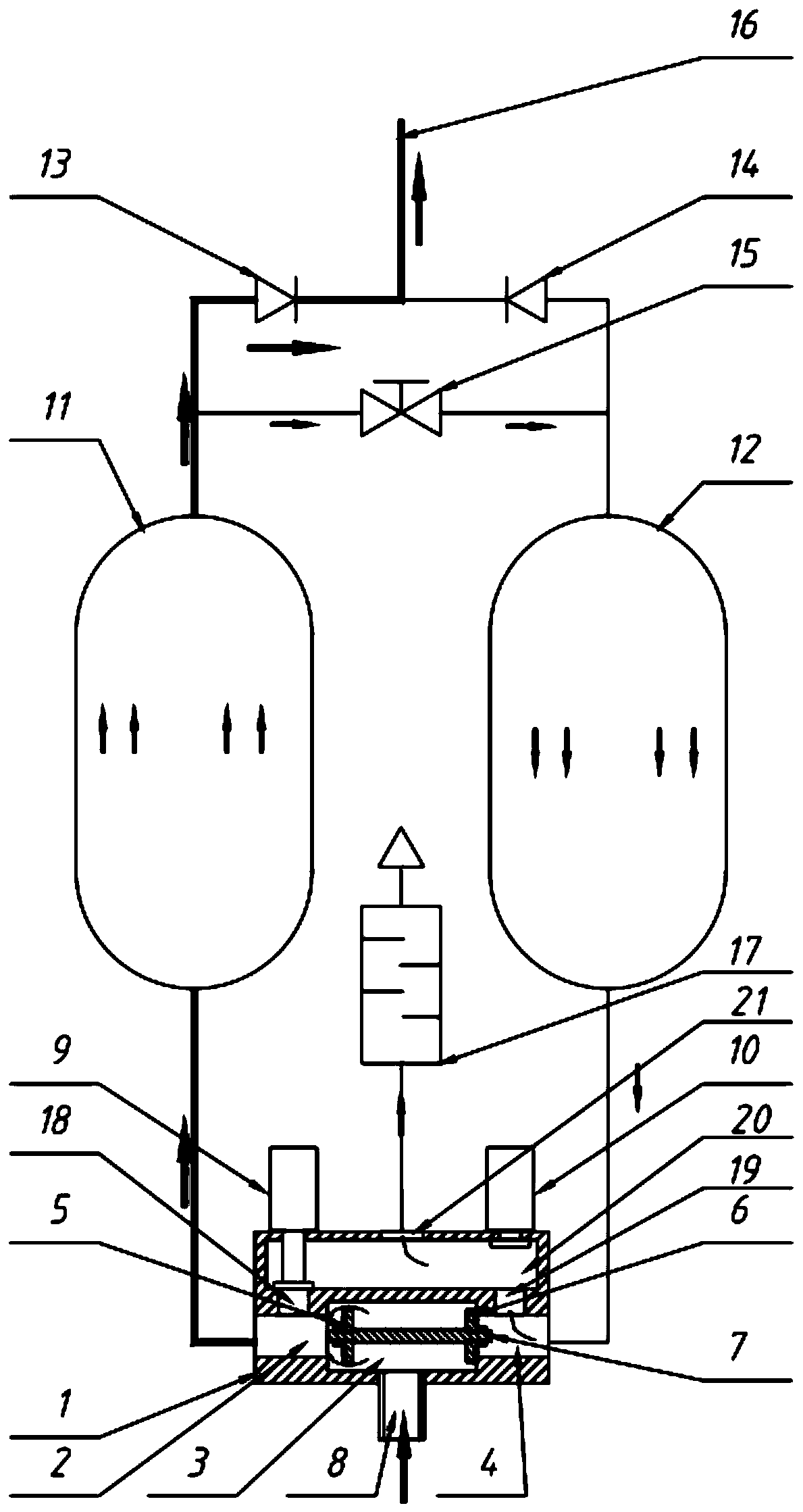

Liquefied natural gas station

ActiveCN102606883AReduce emissions and wasteSimple processPipeline systemsContainer filling under pressureGas phaseEngineering

A liquefied natural gas station comprises a storage tank, a pump, a gas dispenser, an electric control system, valves and pipelines, and is characterized in that an unloading liquid-phase opening, a liquid inlet of the pump and a liquid outlet at the bottom of the storage tank are connected by the valves and the pipelines, an unloading gas-phase opening, a gas return opening of the pump and a gas-phase opening on the upper portion of the storage tank are connected by the valves and the pipelines, after a liquid inlet and a liquid return opening of the gas dispenser are connected in parallel by a pipeline and a valve to form a parallel connection circuit, one end of the parallel connection circuit is connected with an upper liquid inlet and a lower liquid inlet of the storage tank in parallel by pipelines, and the other end of the parallel connection circuit is connected with a liquid outlet of the pump by a valve and a pipeline. Alternatively, the unloading liquid-phase opening, the liquid inlet of the pump and the liquid outlet at the bottom of the storage tank are connected by the valves and the pipelines, the unloading gas-phase opening, a liquid outlet of the pump and the gas-phase opening of the upper portion of the storage tank are connected by the valves and the pipelines, the gas-phase opening of the storage tank is directly connected with the gas return opening by a valve and a pipeline, after the liquid inlet and the liquid return opening of the gas dispenser are connected in parallel by pipelines and a valve to form a parallel connection circuit, one end of the parallel connection circuit is connected with the upper liquid inlet and the lower liquid inlet of the storage tank in parallel by pipelines, and the other end of the parallel connection circuit is connected with the liquid outlet of the pump by a valve and a pipeline.

Owner:沈军

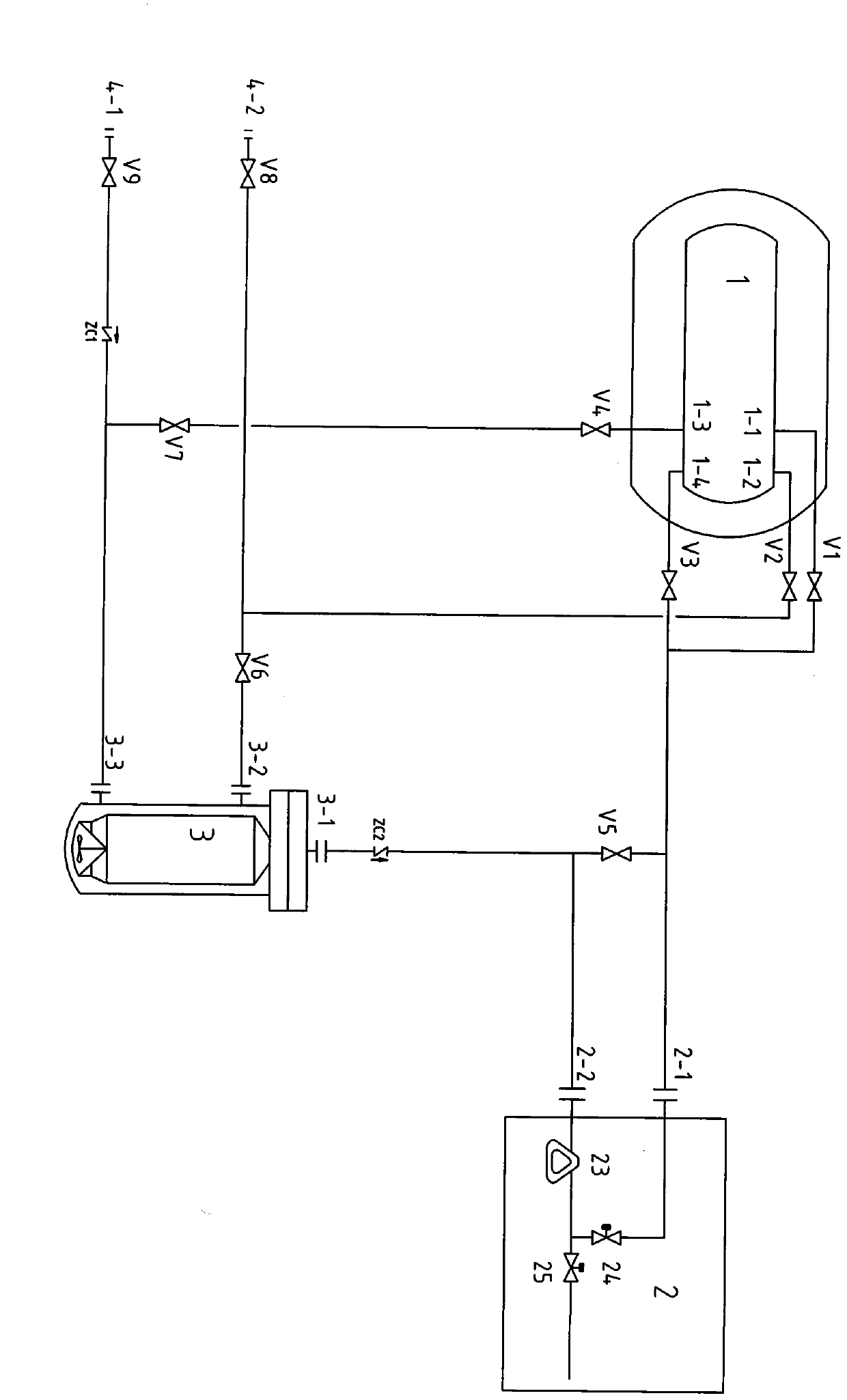

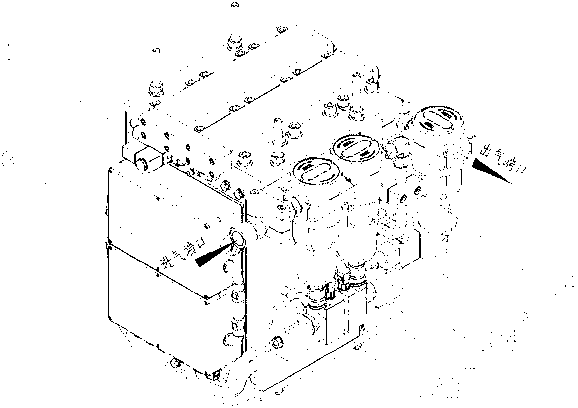

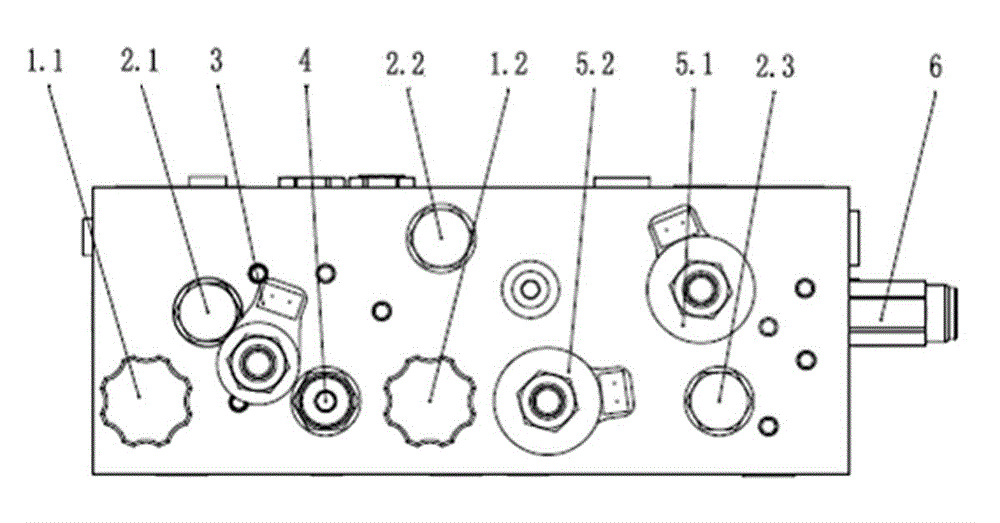

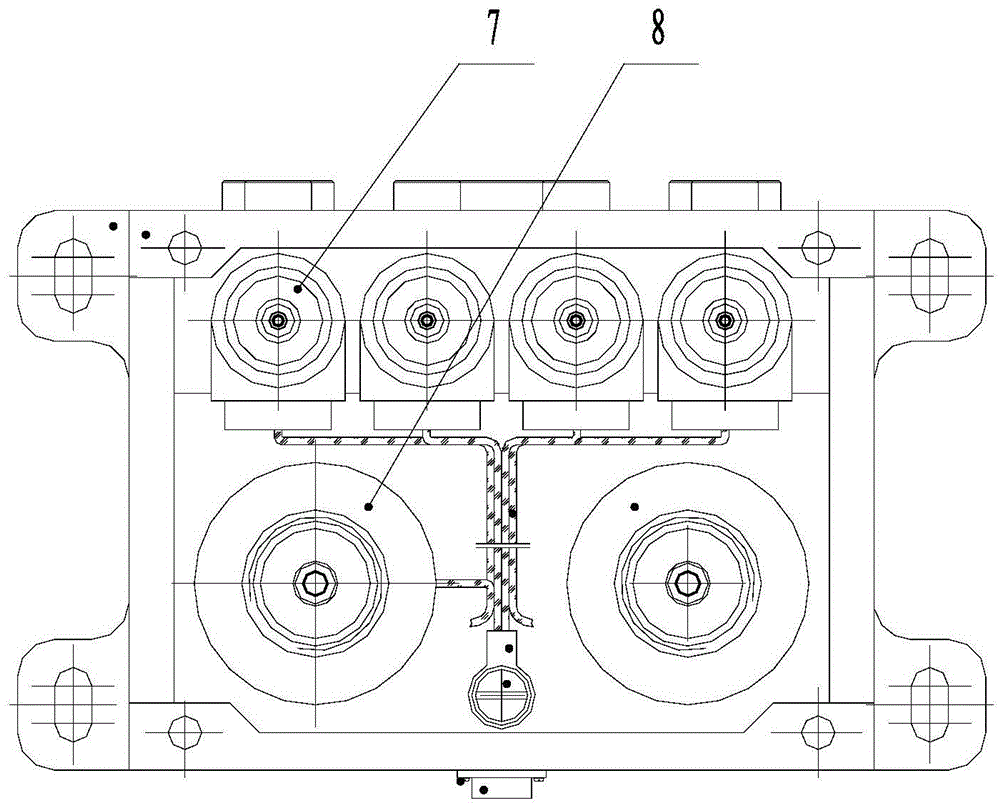

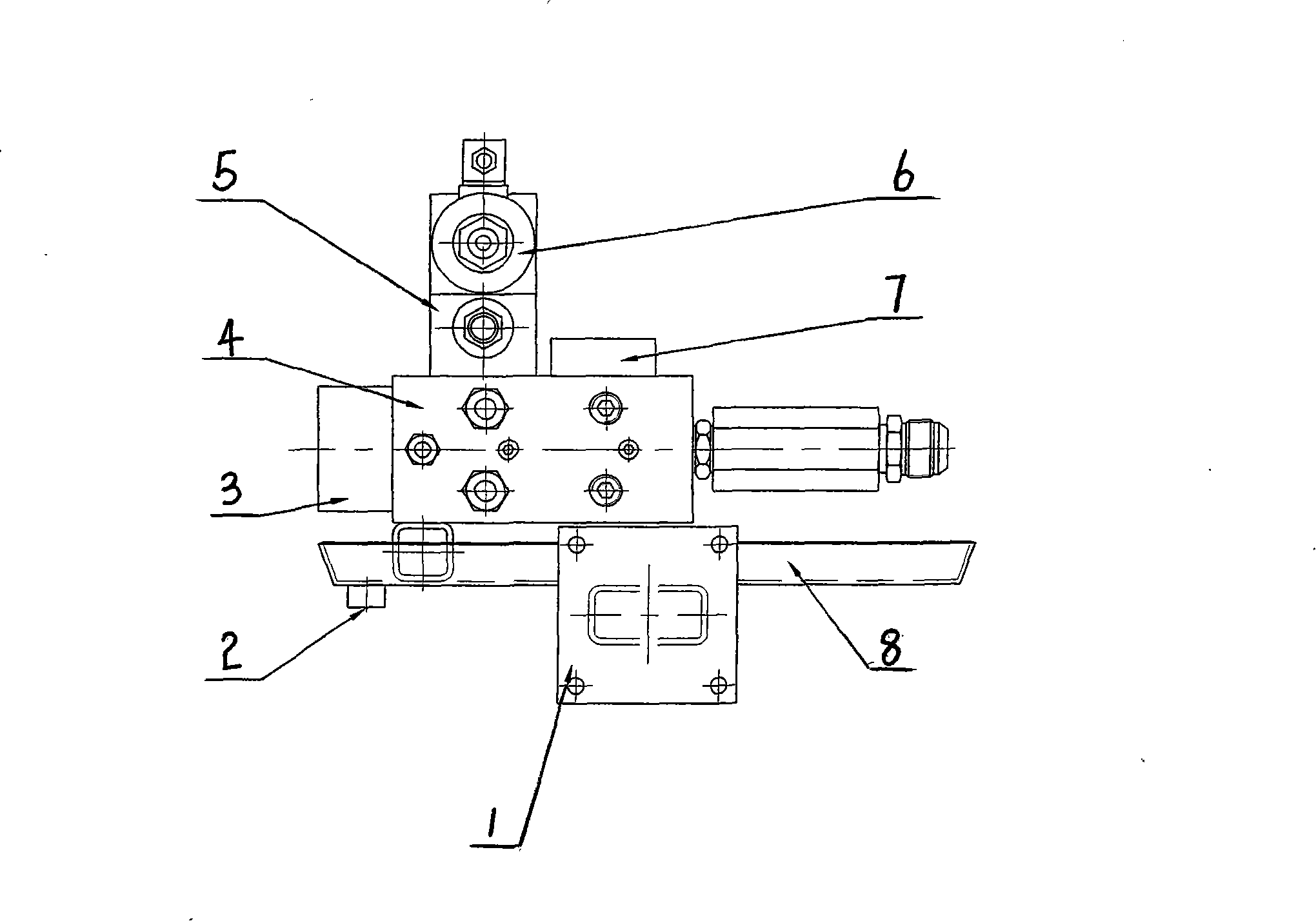

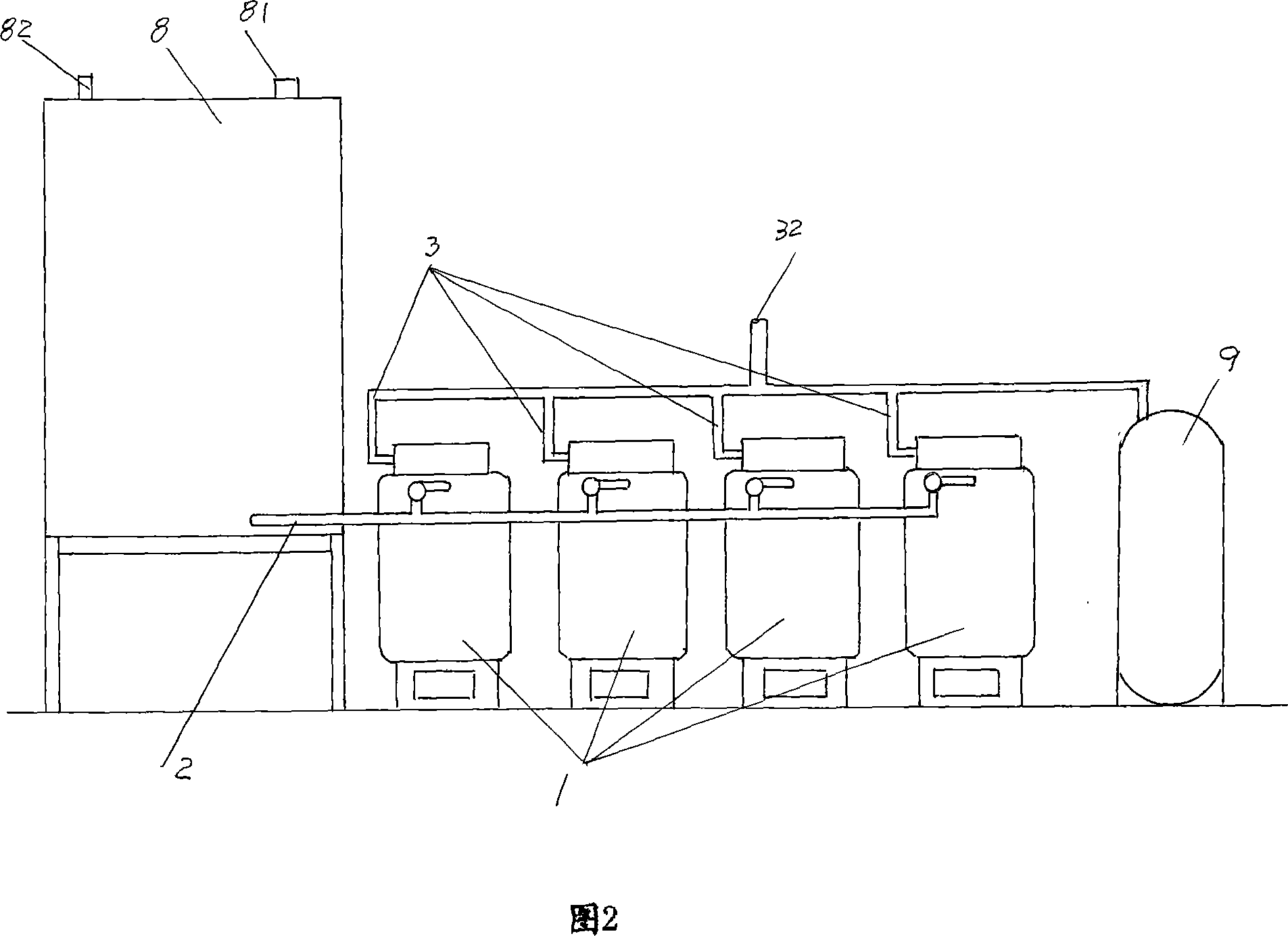

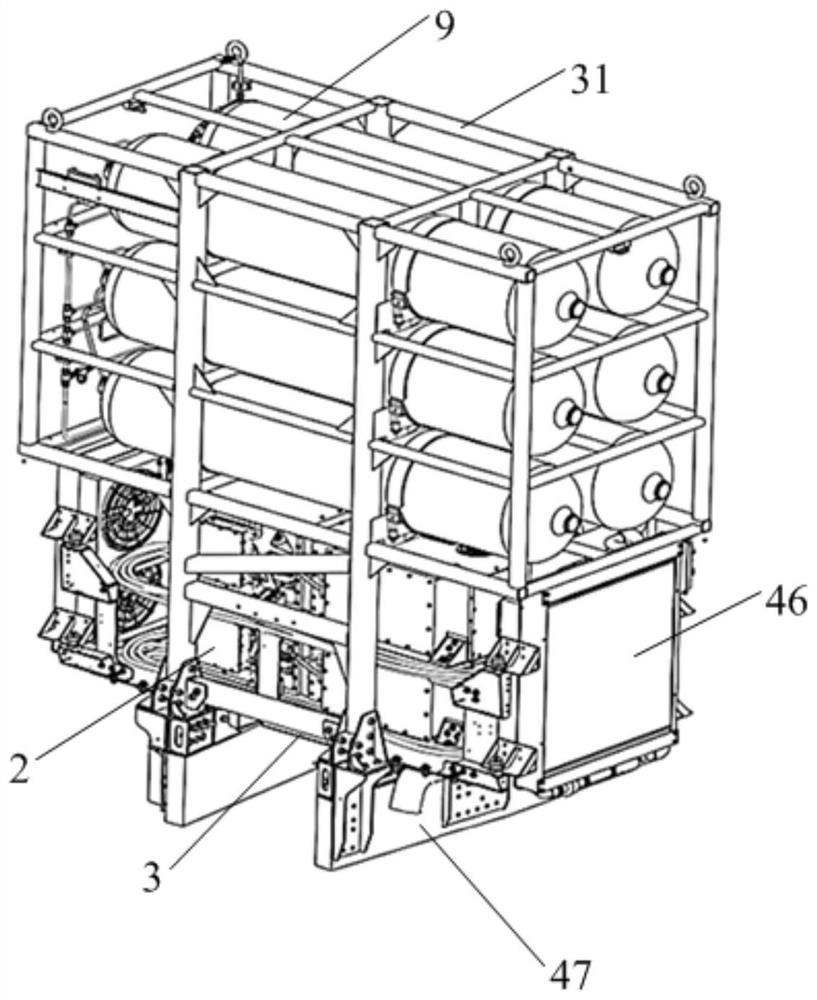

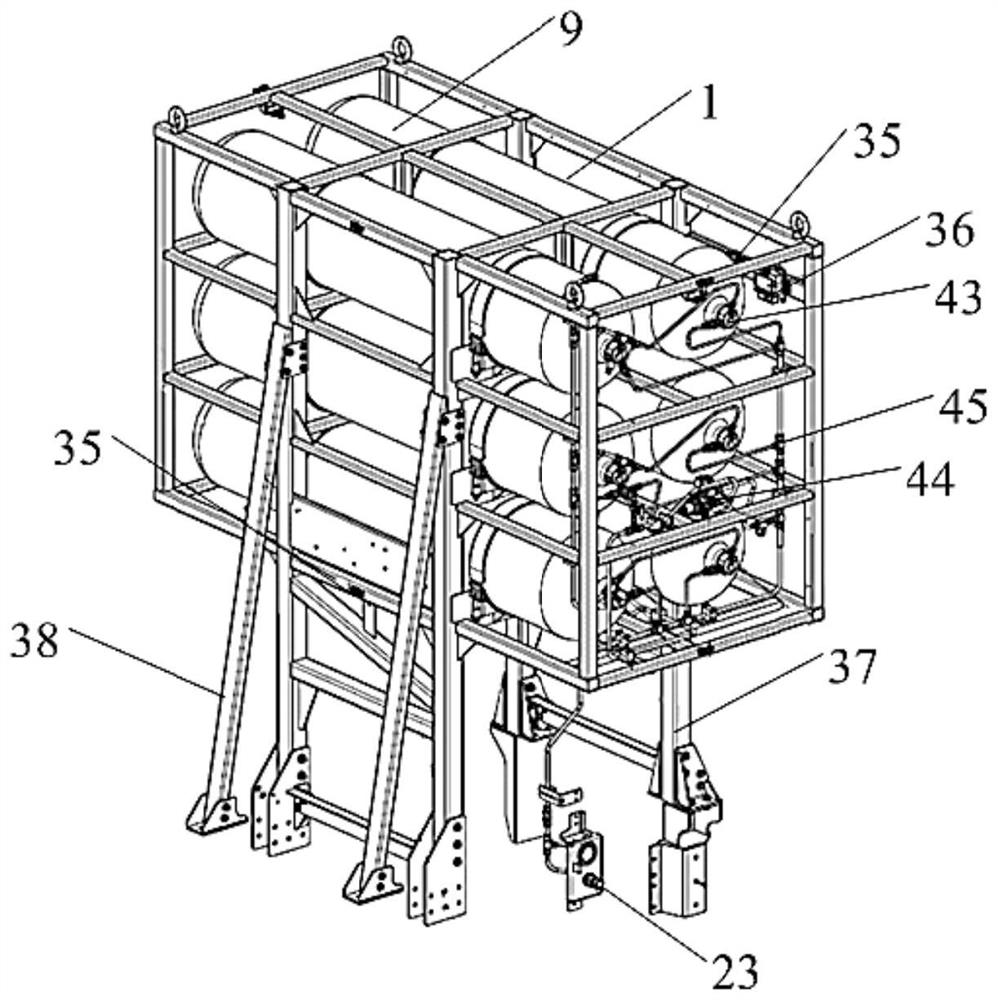

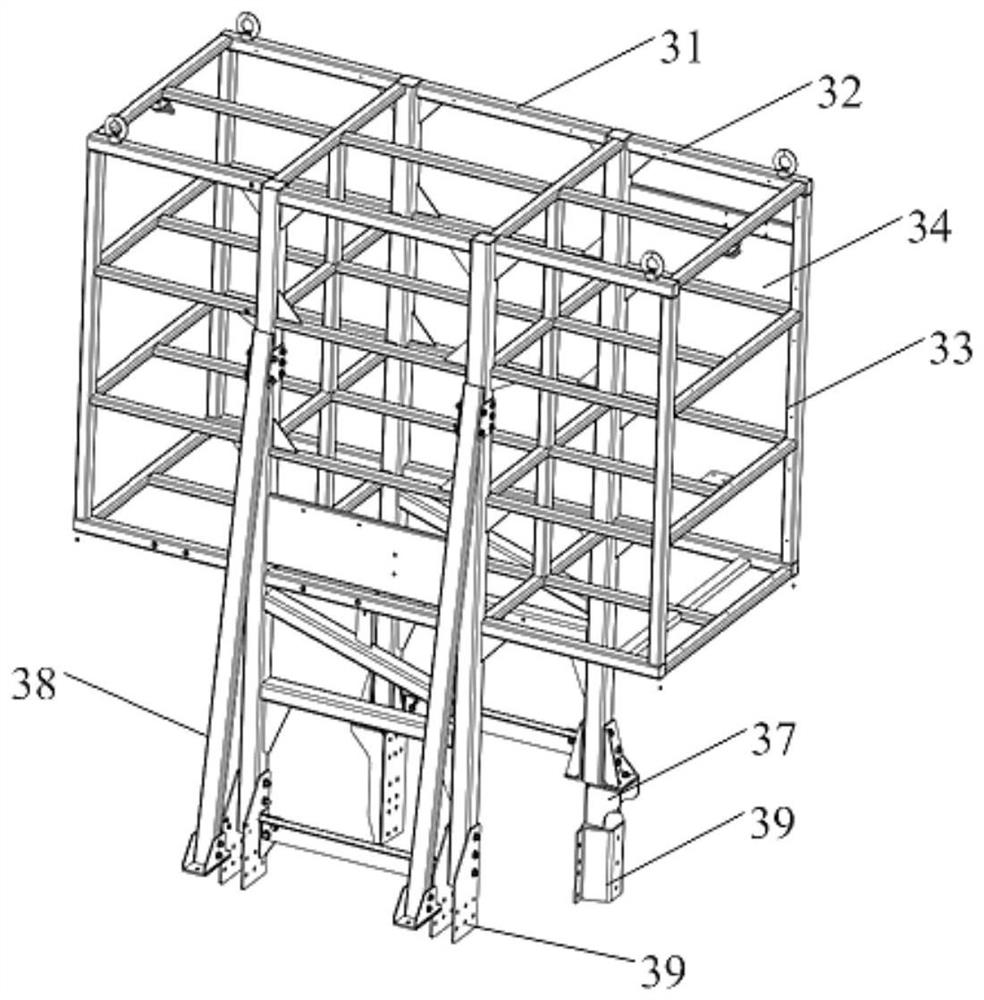

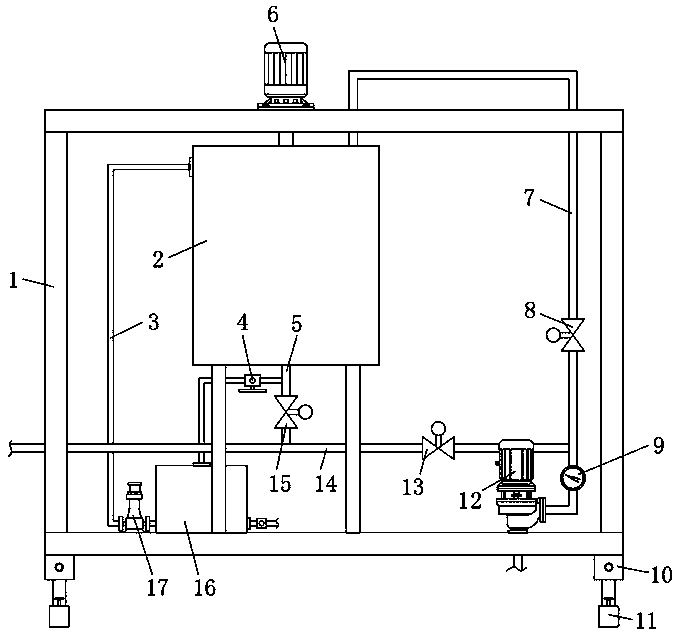

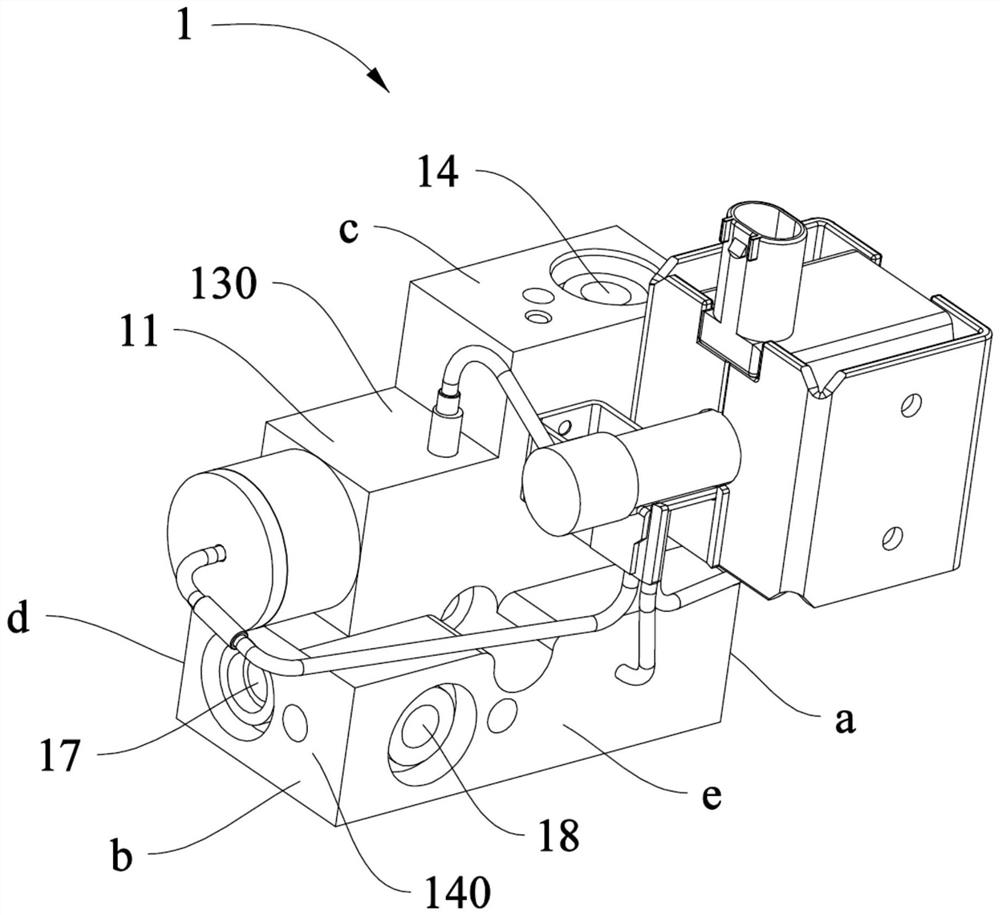

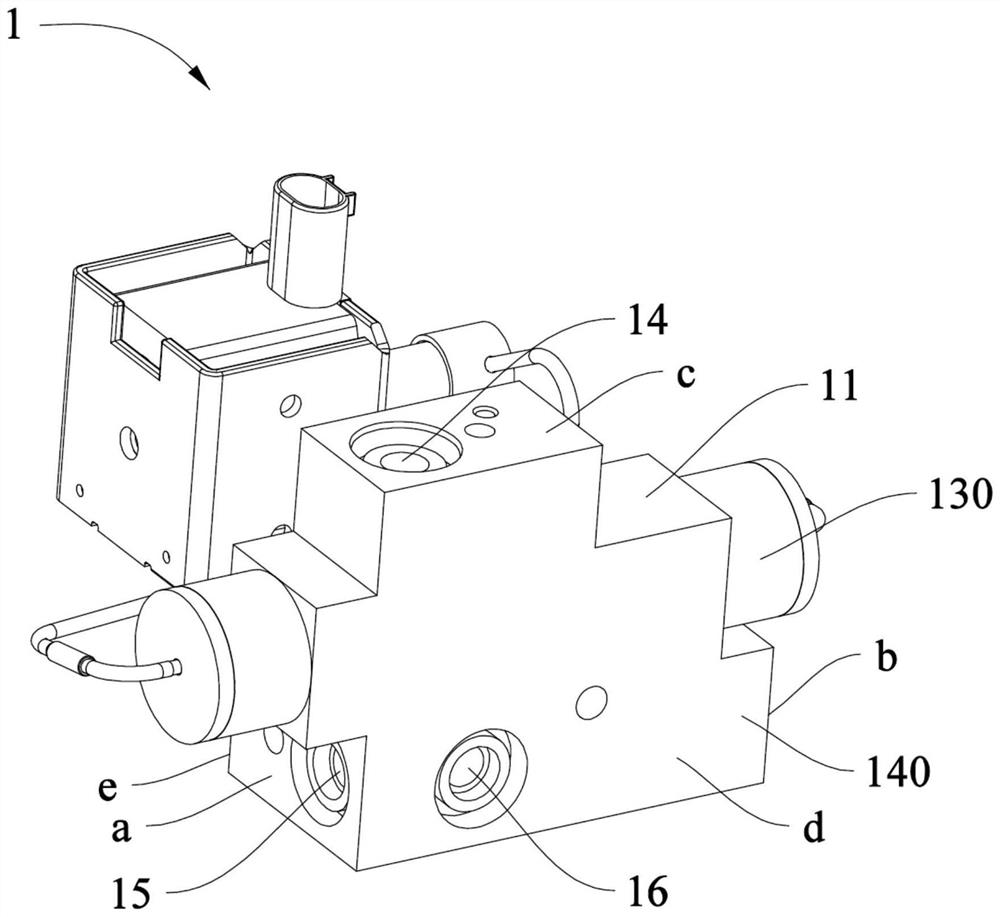

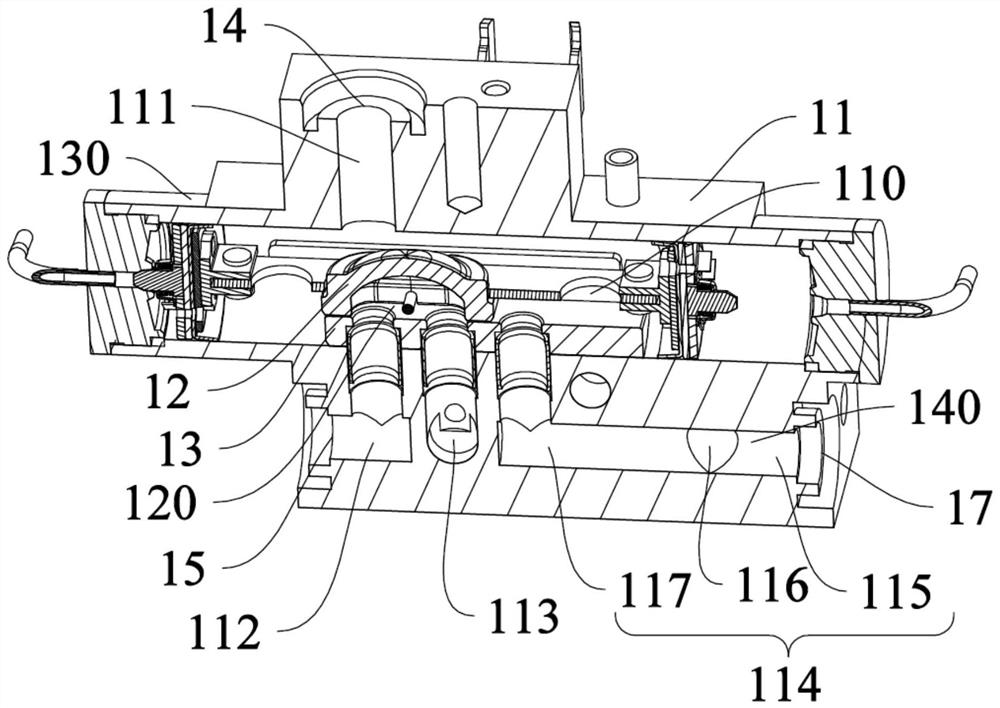

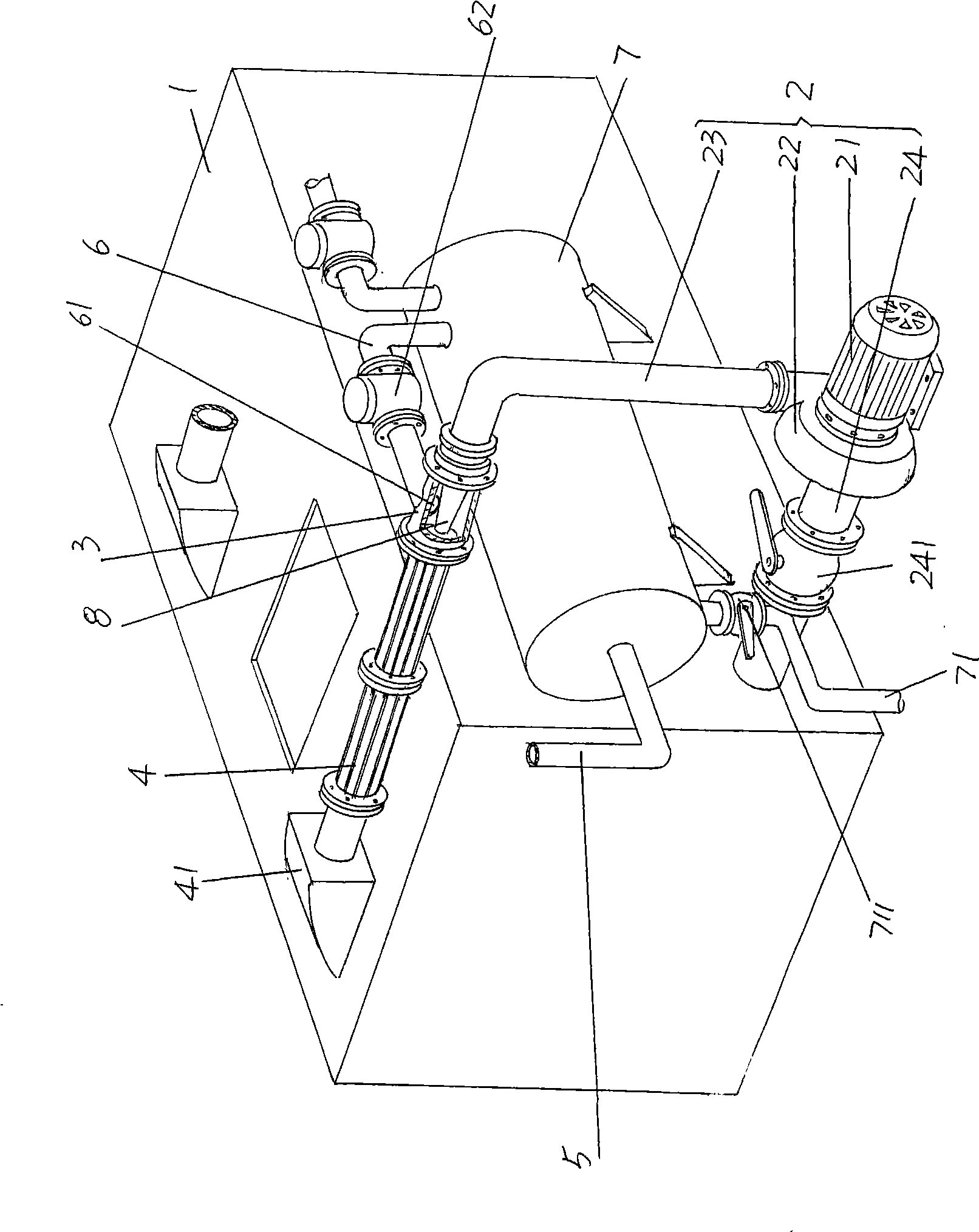

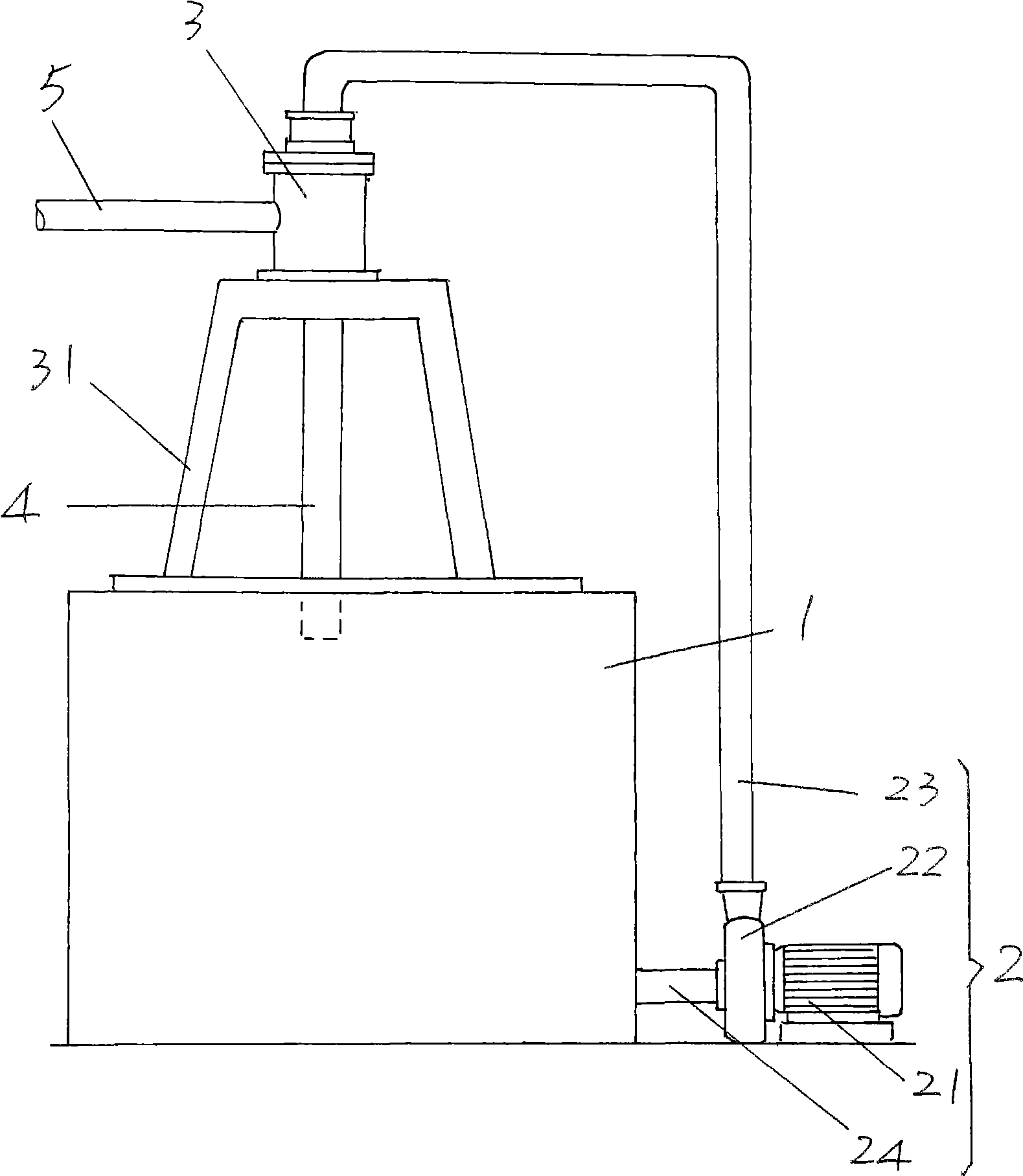

Modular integrated compressed air purification device

ActiveCN103100285ACompact and reasonable structureReduce pipelineCombination devicesOil–water separatorEnergy consumption

The invention discloses a modular integrated compressed air purification device, and aims to provide the modular integrated compressed air purification device characterized by a more compact structure, a small space occupation rate, more convenient installation and maintenance, and small energy consumption. The modular integrated compressed air purification device comprises a dryer (1), an oil-water separator (2) disposed on a side wall of the dryer (1), a high efficiency filter (3), and a dust filter (4). The unpurified compressed air output from an upstream air compressor is treated by the oil-water separator (2), the high efficiency filter (3), the dryer (1) and the dust filter (4) in order, and is then delivered to downstream gas consumption equipment. The modular integrated compressed air purification device provided in the invention can be widely applied in the field of compressed air purification.

Owner:ZHUHAI HECA PURIFICATION TECH

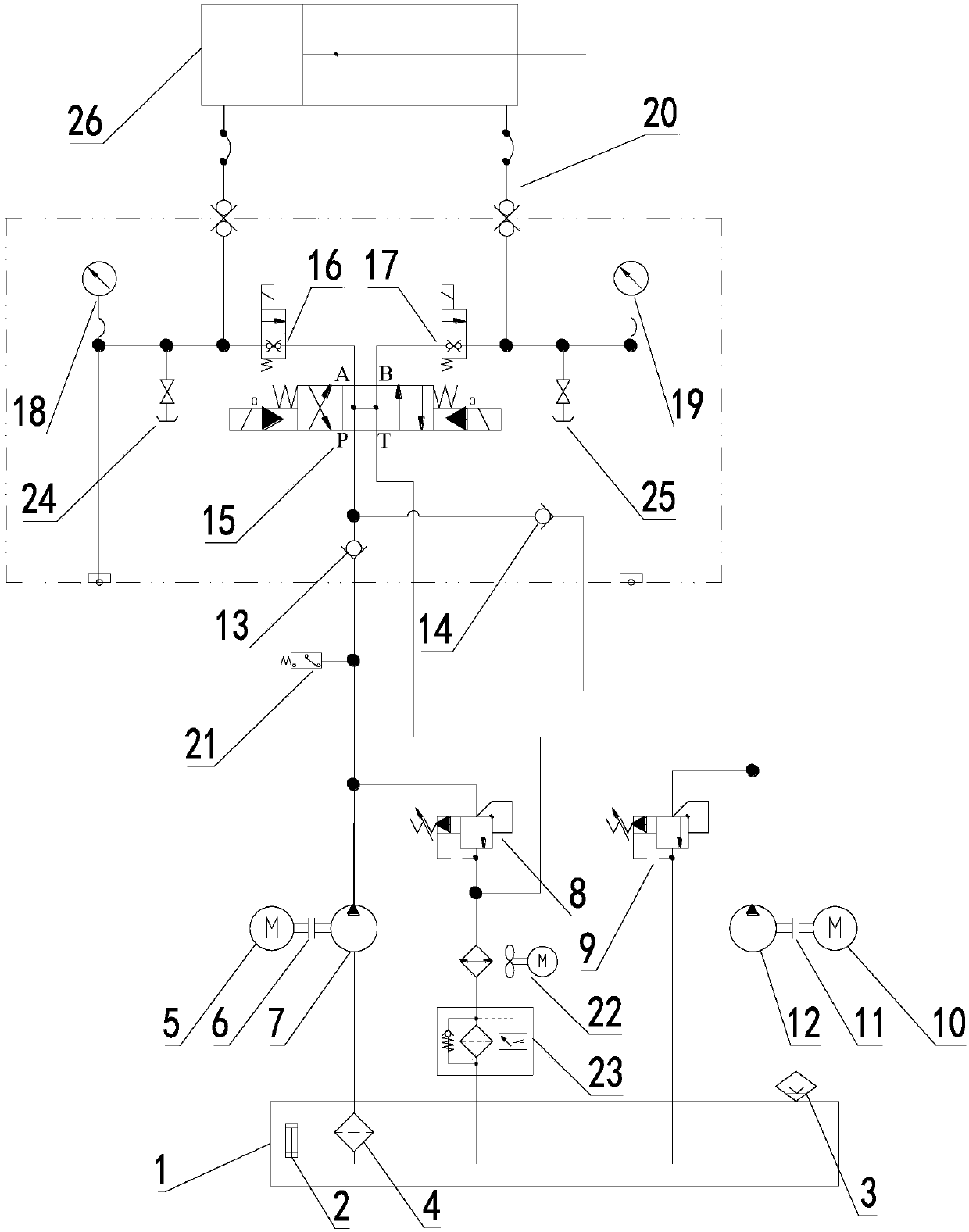

Mining dump truck hydraulic brake control integrated system with large electric wheel

ActiveCN104401306AHigh working reliabilityHigh level of integrationFluid braking transmissionHigh pressureShuttle valve

The invention discloses a mining dump truck hydraulic brake control integrated system with large electric wheel. The mining dump truck hydraulic brake control integrated system with large electric wheel comprises a variable pump, an oil tank, a high-pressure oil filter, a front wheel brake, a rear wheel brake, a parking brake, a brake pedal valve, a front guide control valve, a rear guide control valve, a first energy accumulator, a second energy accumulator, a second shuttle valve, the mining dump truck hydraulic brake control integrated system with large electric wheel further comprises a brake control integrated valve group provided with a plurality of cartridge valves, the variable pump is connected with the brake control integrated valve group via the high-pressure oil filter. The mining dump truck hydraulic brake control integrated system with large electric wheel is high in work reliability, simple in manufacture, low in use cost, the standard general hydraulic components are integrated into the hydraulic brake control system, the elements are concentrated with high integration degree, small space usage, little pipeline and convenient maintenance; the operation is simple, the function is strong, the automation control degree is high, the action interlocking relationship is perfect, the safety performance is high for brake control for large mining dump truck equipment.

Owner:HUNAN XD HEAVY EQUIP

Hydraulic oil cylinder loading test hydraulic system

InactiveCN107725536AReduce installed powerReduce manufacturing costFluid-pressure actuator testingEngineeringHigh pressure

The invention discloses a hydraulic oil cylinder loading test hydraulic system which includes an oil tank body, a test system, a power system and a tested oil cylinder. The test system includes an H-type functional electromagnetic reversing valve, a plug-in mounting type left electromagnetic ball valve connected with a port A, a plug-in mounting type right electromagnetic ball valve connected witha port B, two manual ball valves and two pressure gauges. The power system includes a liquid filling unit and a loading unit. The upper part of the liquid filling unit is provided with a pressure switch and a one-way valve in turn, is connected to a port P of the electromagnetic reversing valve, and is in parallel connection with a low pressure overflow valve. The loading unit is connected to theport P of the electromagnetic reversing valve through the check valve, converges with the liquid filling unit, and is in parallel connection with a high pressure overflow valve. The installed power of the system is reduced by double-pump converging configuration, the pressure switch is adopted to detect loading pressure, the operation is convenient and reliable, and no energy waste is caused.

Owner:四川坤成润科技有限公司

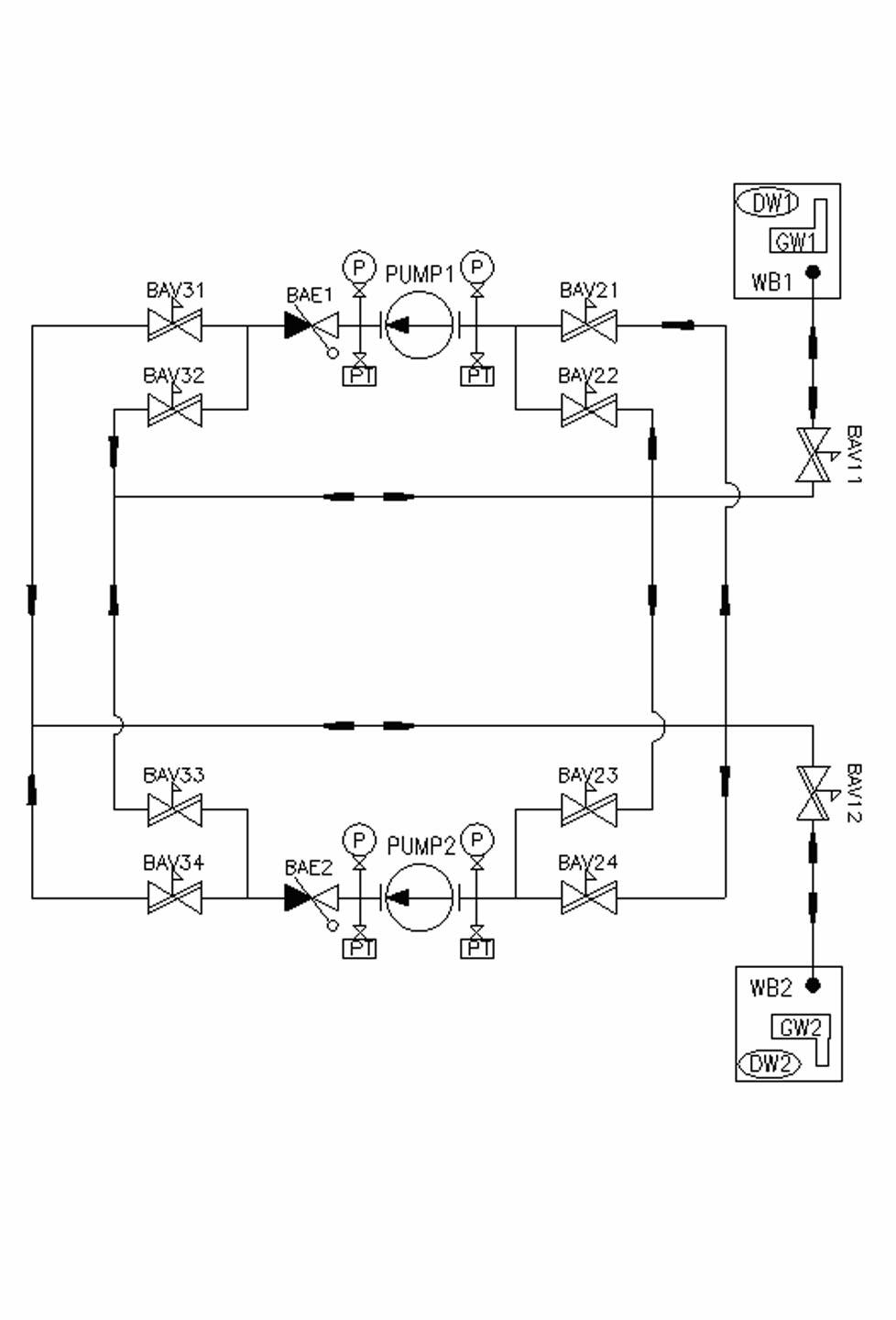

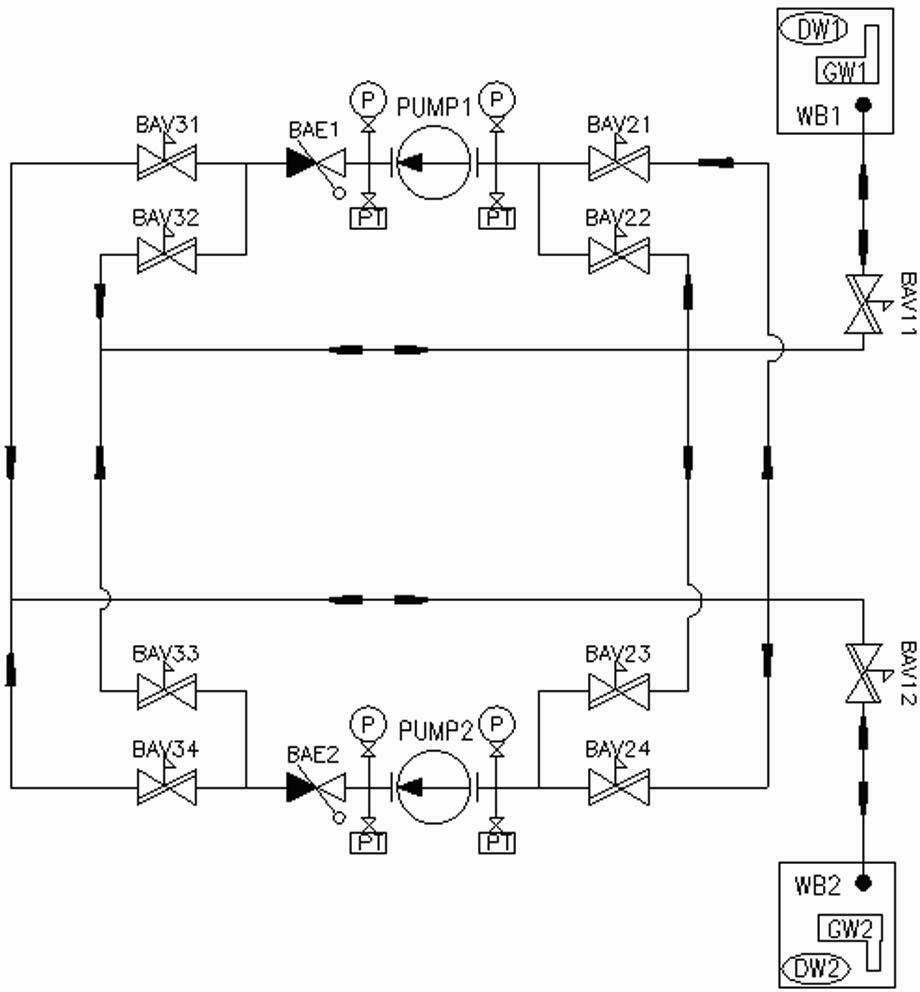

Automatic anti-heeling system for ballast pump

The invention discloses an automatic anti-heeling system for a ballast pump, belonging to the technical field of ships. The system comprises a control system, an inclinometer, instruments, a ballast pump, remote-control butterfly valves, plate-type check valves, ballast tanks, a high liquid-level sensor and a low liquid-level sensor, wherein the instruments are installed at two sides of the ballast pump; the plate-type check valves are installed at the left side of the ballast pump; two paths of pipelines comprising an interior pipeline and an exterior pipeline are connected in parallel between the two plate-type check valves; two paths of pipelines comprising an interior pipeline and an exterior pipeline are connected in parallel at the right side of the ballast pump; two interior pipelines and the remote-control butterfly valve BAV11 are communicated via a pipeline and then connected into the ballast tank WB1; two exterior pipelines and the remote-control butterfly valve BAV12 are communicated via another pipeline and then connected into the ballast tank WB2; and the high liquid-level sensor and the low liquid-level sensor are installed in the ballast tanks. The control system controls the operations of the ballast pump and the remote-control butterfly valves by outputting signals via the inclinometer, the high liquid-level sensor and the low liquid-level sensor. Through the system, a large number of separately-arranged anti-heeling devices and pipelines, the corresponding installation space and the production cycle are saved.

Owner:YANGFAN GROUP

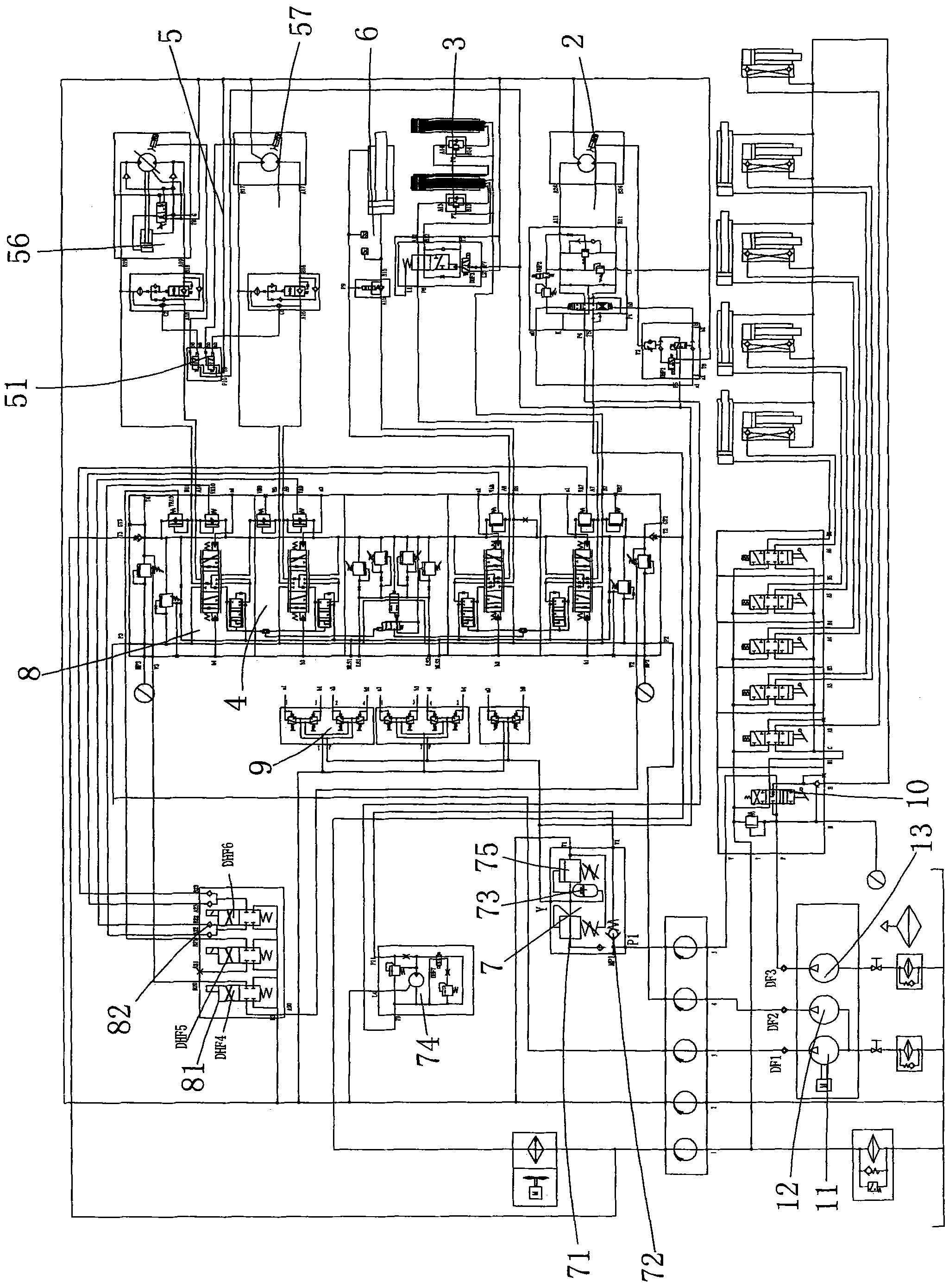

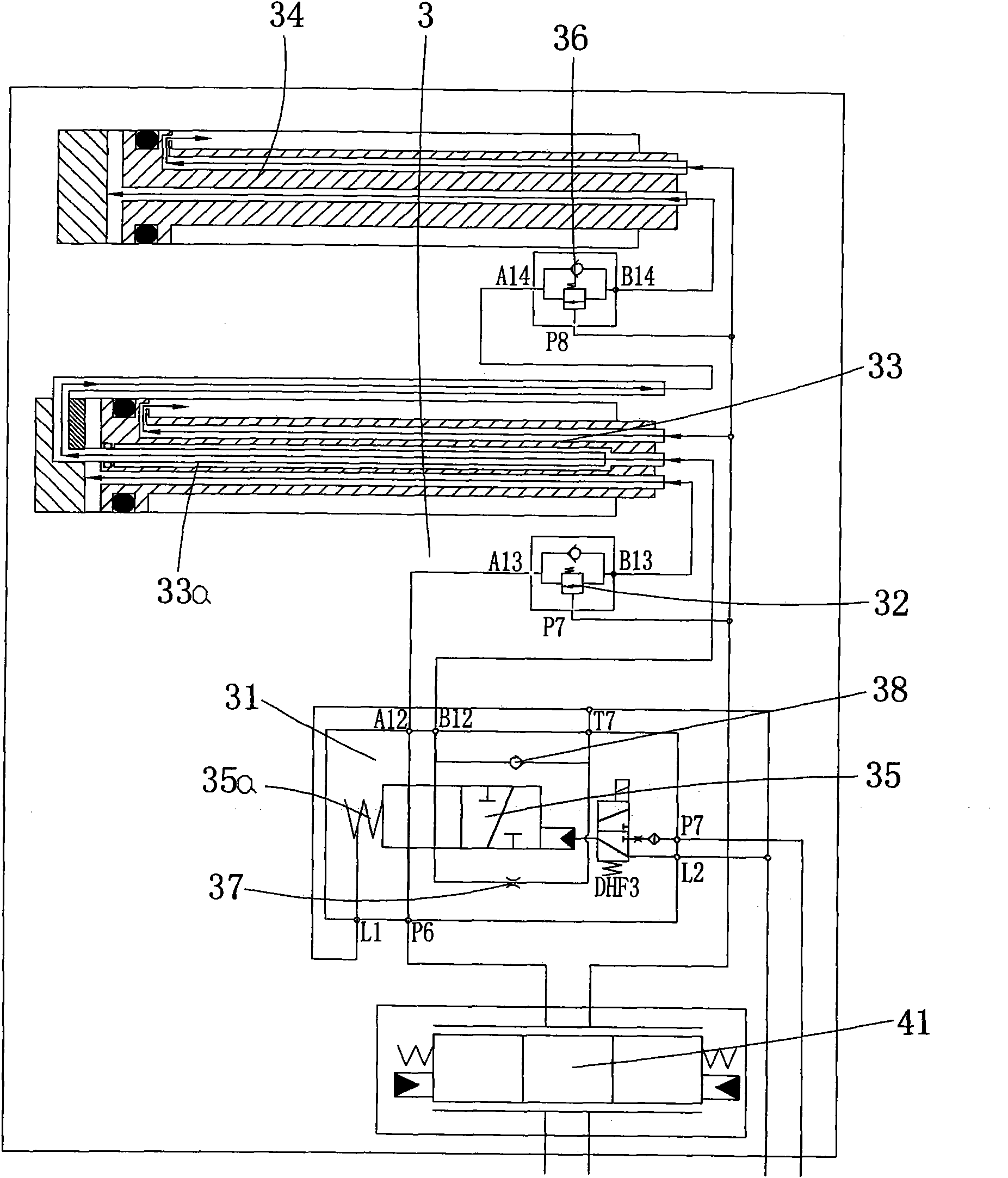

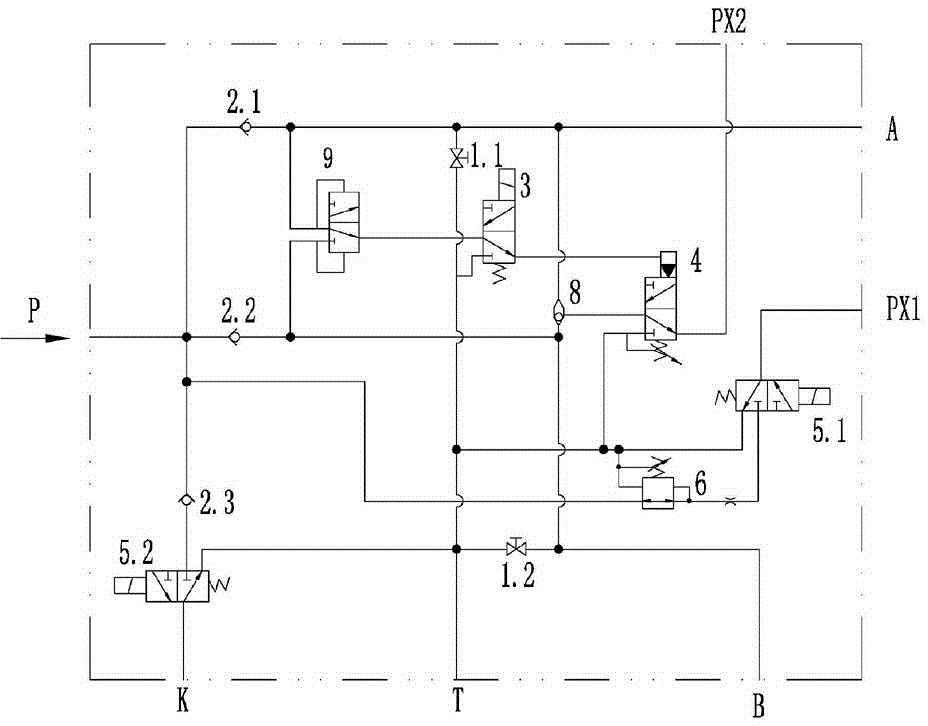

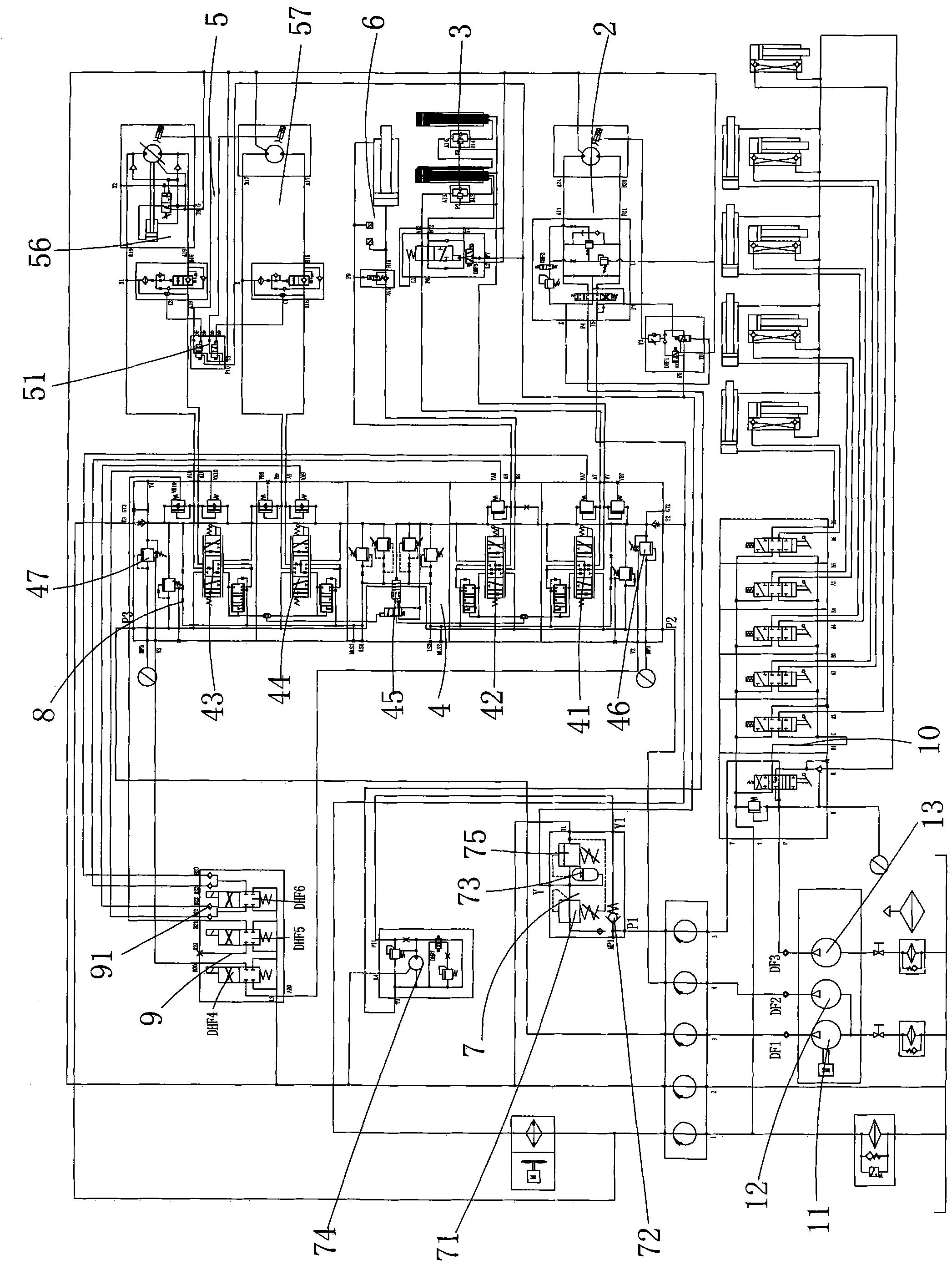

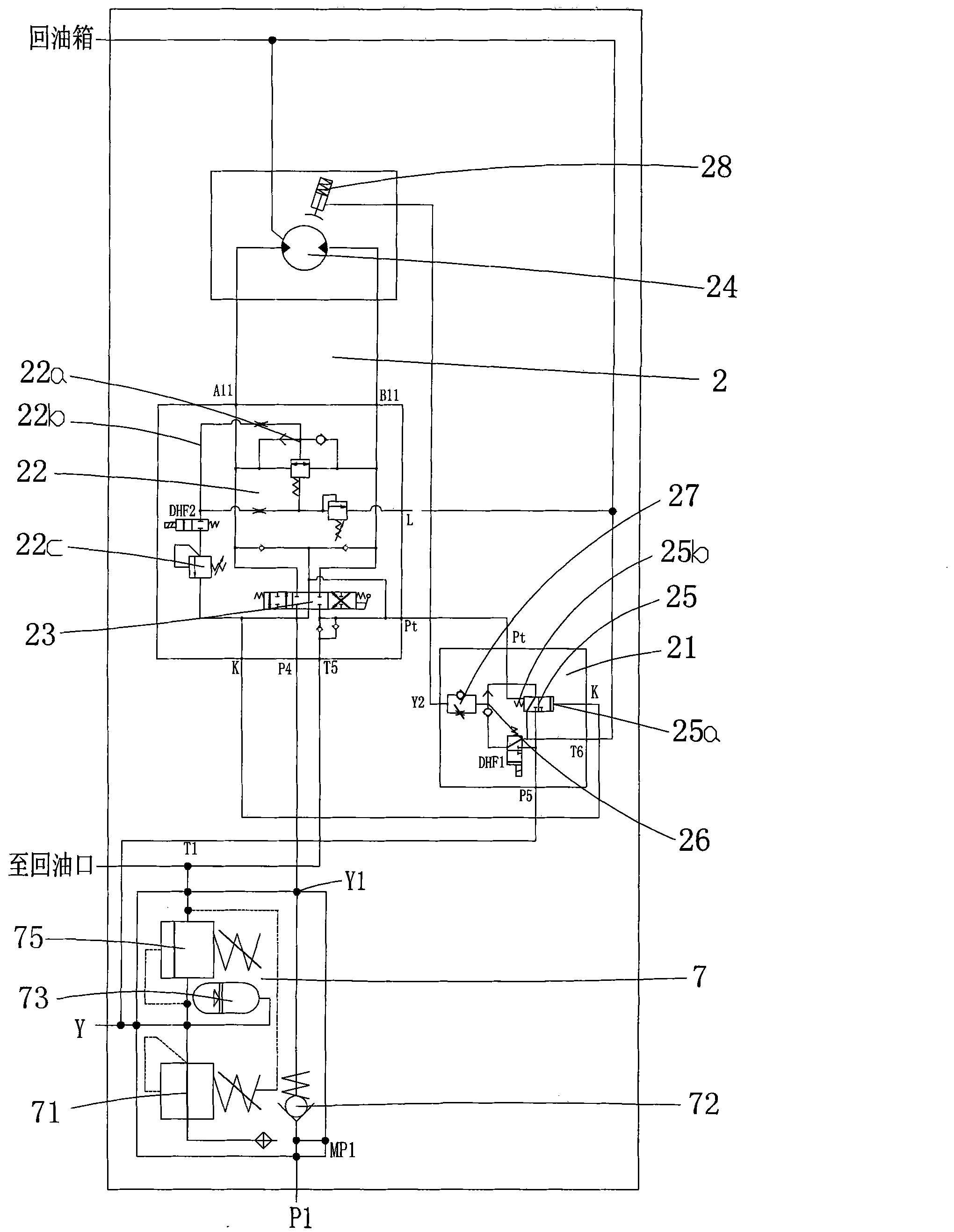

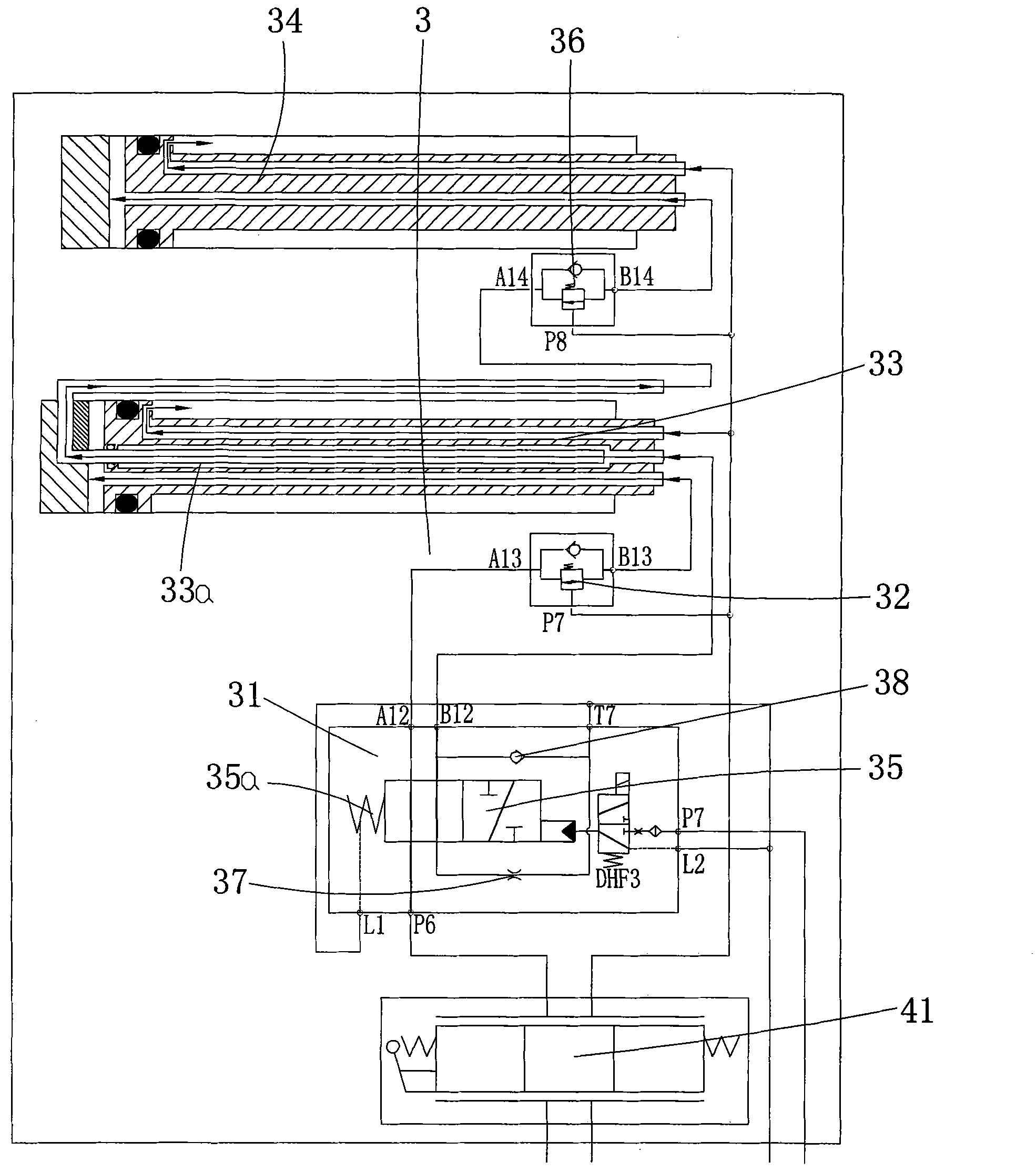

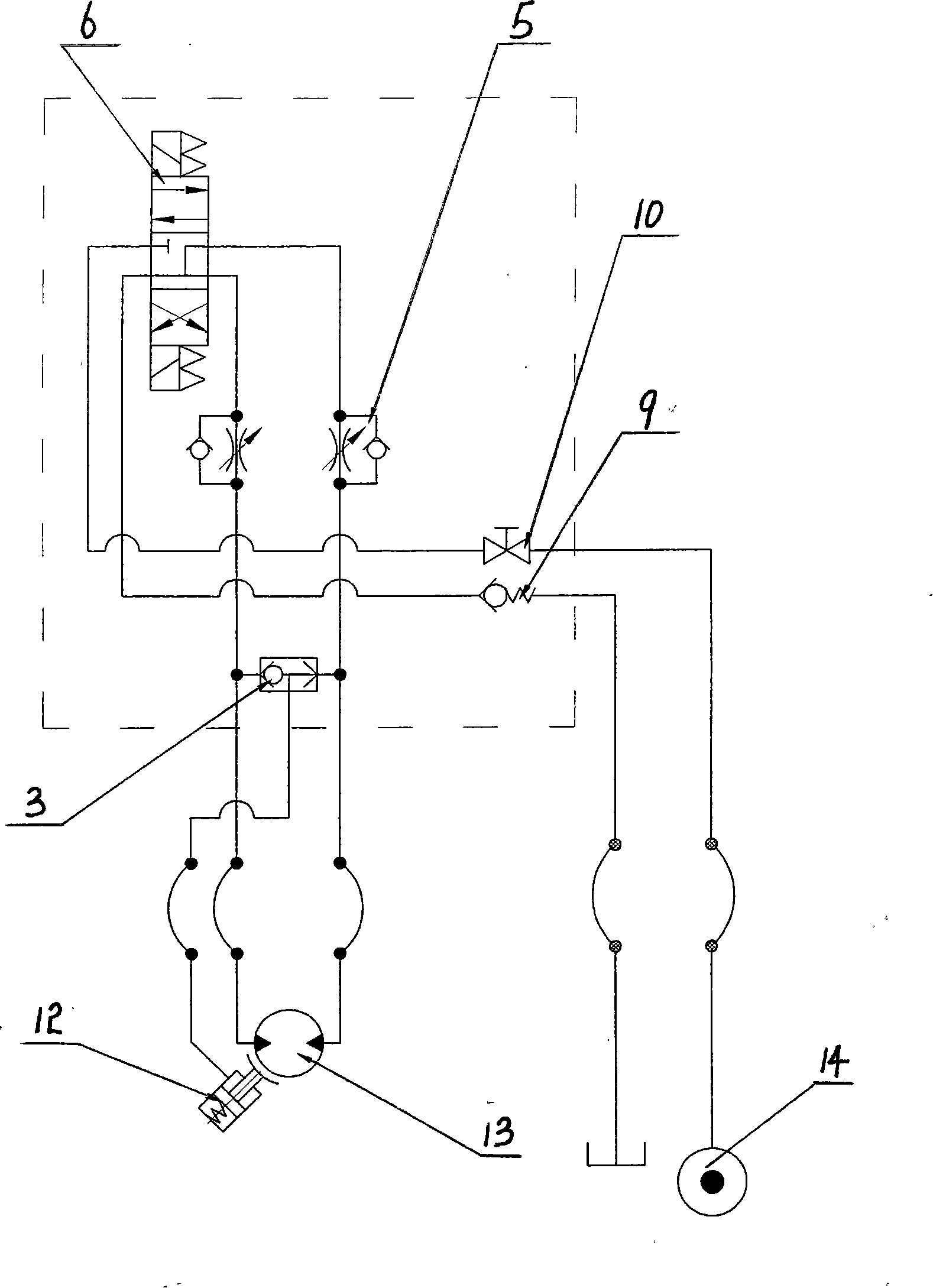

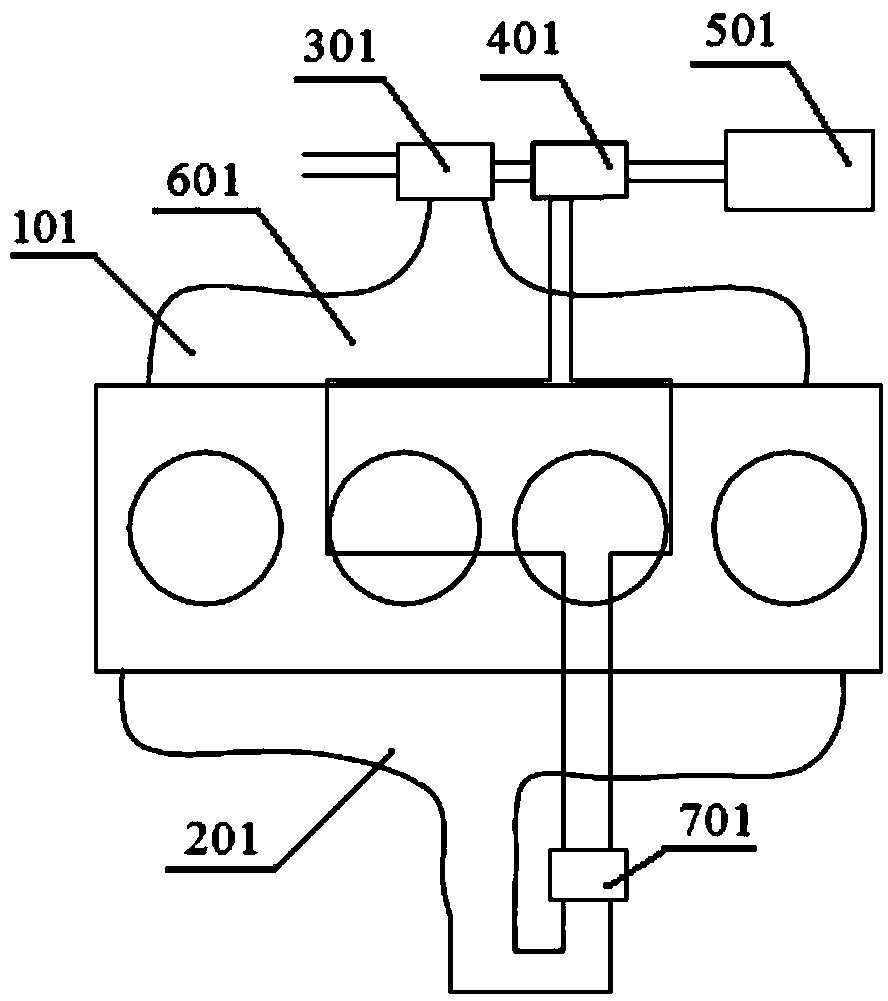

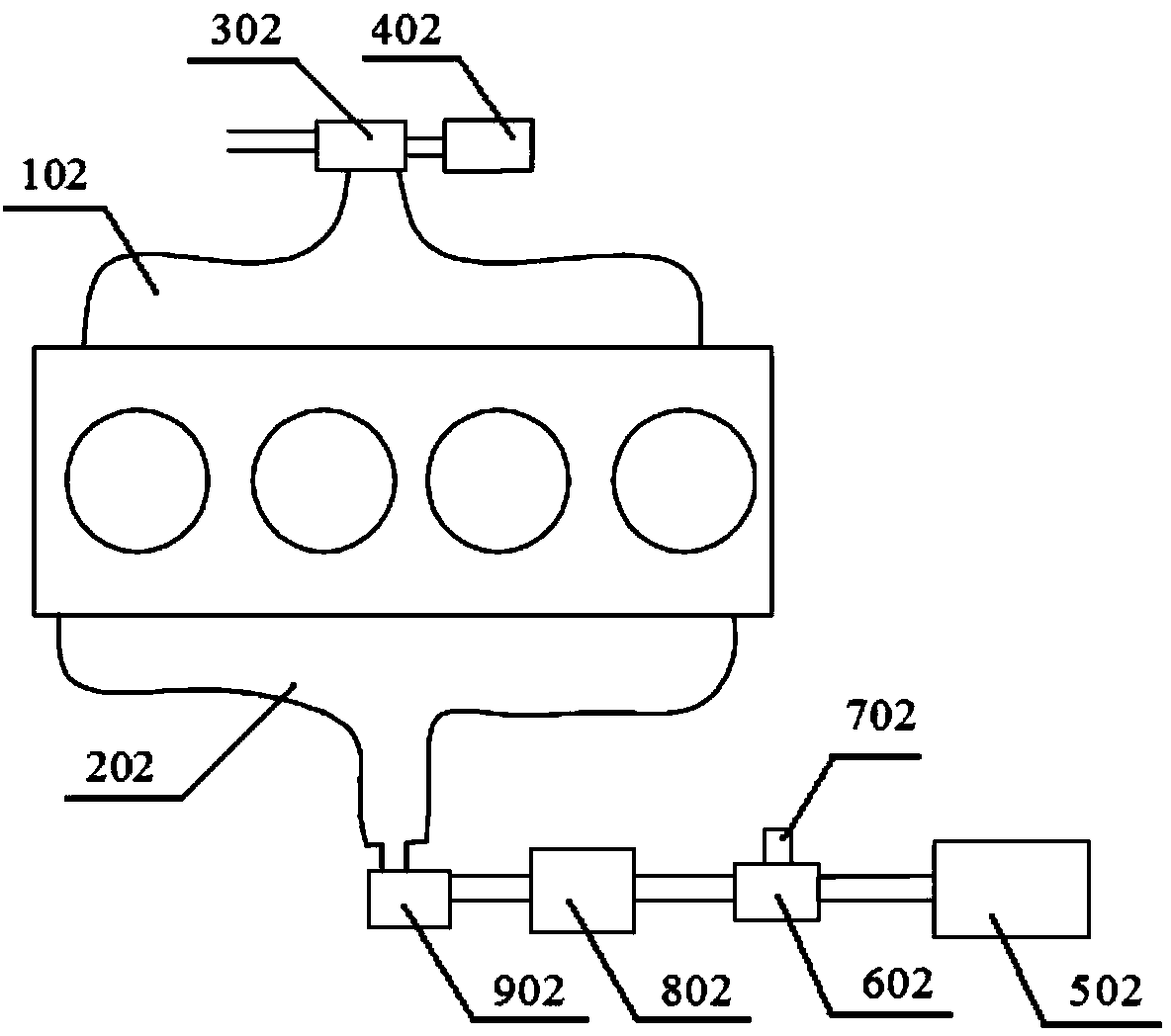

Hydraulic system of mechanically operated triple pump

ActiveCN101857174AEliminate pressure shocksReduce pipelineLoad-engaging elementsRemote controlControl manner

The invention relates to a hydraulic system of a mechanically operated triple pump, comprising a first oil pump, a second oil pump, a third oil pump, a rotary hydraulic system, a boom expansion hydraulic system, a safe unloading hydraulic system, a lifting hydraulic system, a boom amplitude hydraulic system and a decompression pilot oil-source valve group; the opening and closing characteristics of a rotary brake and main and accessory hoisting brakes all adopt a constant-pressure oil-source control mode and intelligently and automatically control the brakes according to the operation of various actions without the need of additional external force operation; according to the different opening and closing characteristics of each mechanism, a rotary structure is in a quick-opening slow-closing control mode, main and accessory hoisting mechanisms are in a slow-opening quick-closing control mode, and the pressure impaction of the system is effectively eliminated, an overflow valve of each working port of a flow distribution valve and overflow valves of two oil-inlet working ports are provided with remote-control oil ports, are connected with a system unloading valve group and directly solve a safety control problem on a main valve; and in a complete vehicle system, elements are highly integrated and modularized, thereby reducing pipelines of the complete vehicle system and being convenient for maintenance.

Owner:YUZHOU HYDRAULIC EQUIP FACTORY

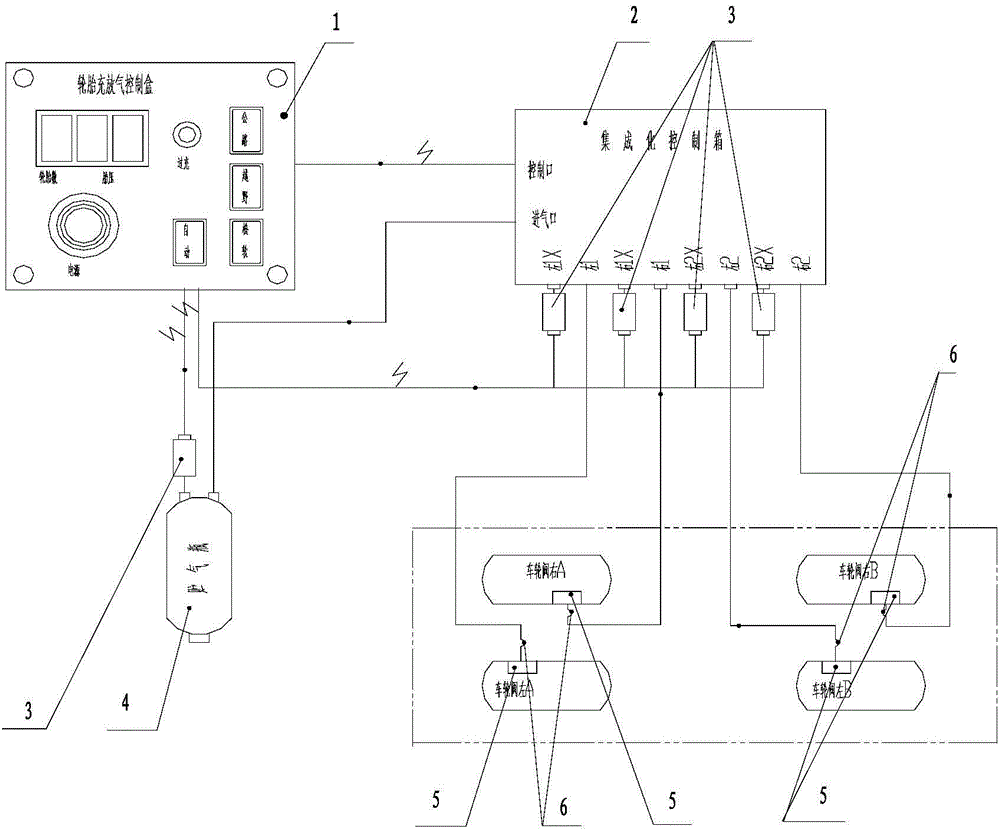

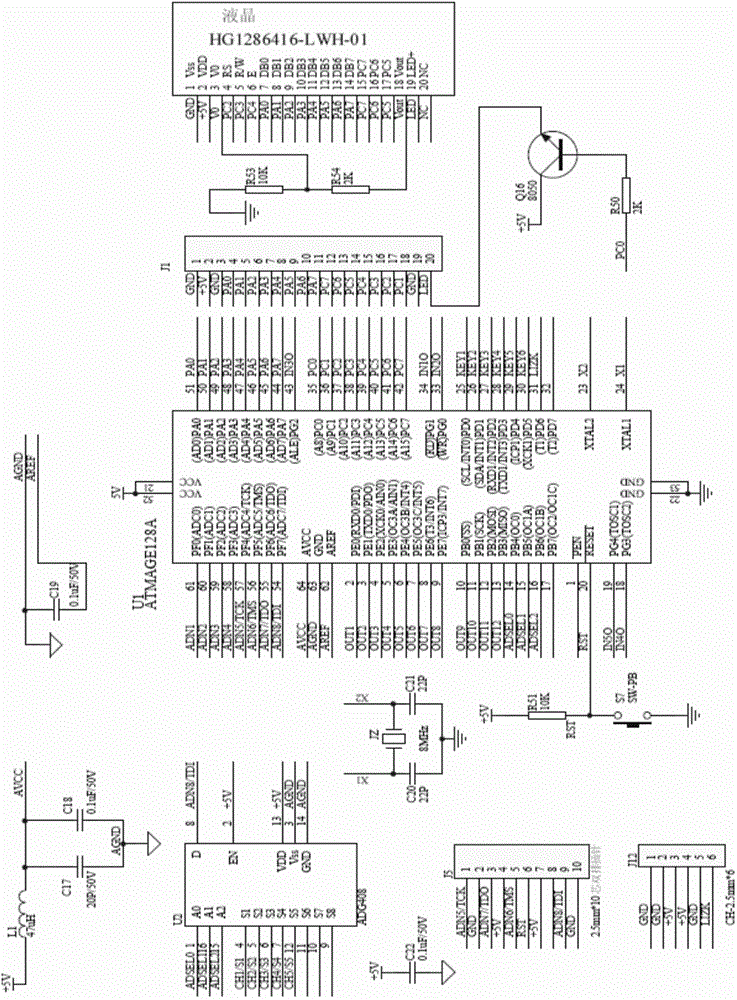

Central tire inflation/deflation system of military wheeled vehicle and wheeled off-road vehicle

InactiveCN104802607ARealize intelligent control requirementsHumanized goodTyre measurementsGas cylinderBottle

The invention discloses a central tire inflation / deflation system of a military wheeled vehicle and a wheeled off-road vehicle. The military wheeled vehicle and the wheeled off-road vehicle comprise N tires, wherein the N is a natural number larger than 1; the central tire inflation / deflation system at least comprises an air pressure signal acquisition terminal, a control terminal and a signal processing terminal; the air pressure signal acquisition terminal comprises a tire inner air pressure sensor for acquiring each tire inner air pressure signal, and a bottle inner air pressure sensor for acquiring an air storage bottle inner air pressure signal; the control terminal is used for sending a control command and displaying the working state of the system; the signal processing terminal is used for receiving command information sent by the control terminal, and carrying out an inflation / deflation / transient state command according to the command information; or the signal processing terminal receives information of the air pressure signal acquisition terminal and sends the received information to the control terminal to display. The central tire inflation / deflation system of the military wheeled vehicle and the wheeled off-road vehicle can regulate and control air pressure of each tire according to the road conditions.

Owner:天津市航翔科技发展有限公司

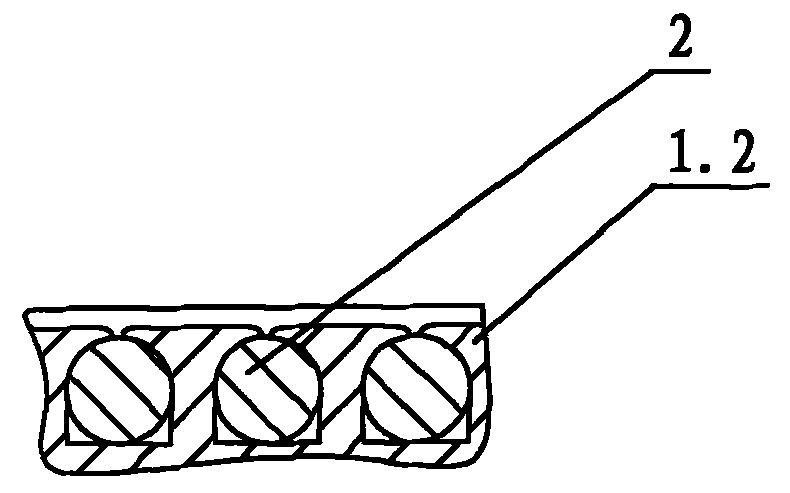

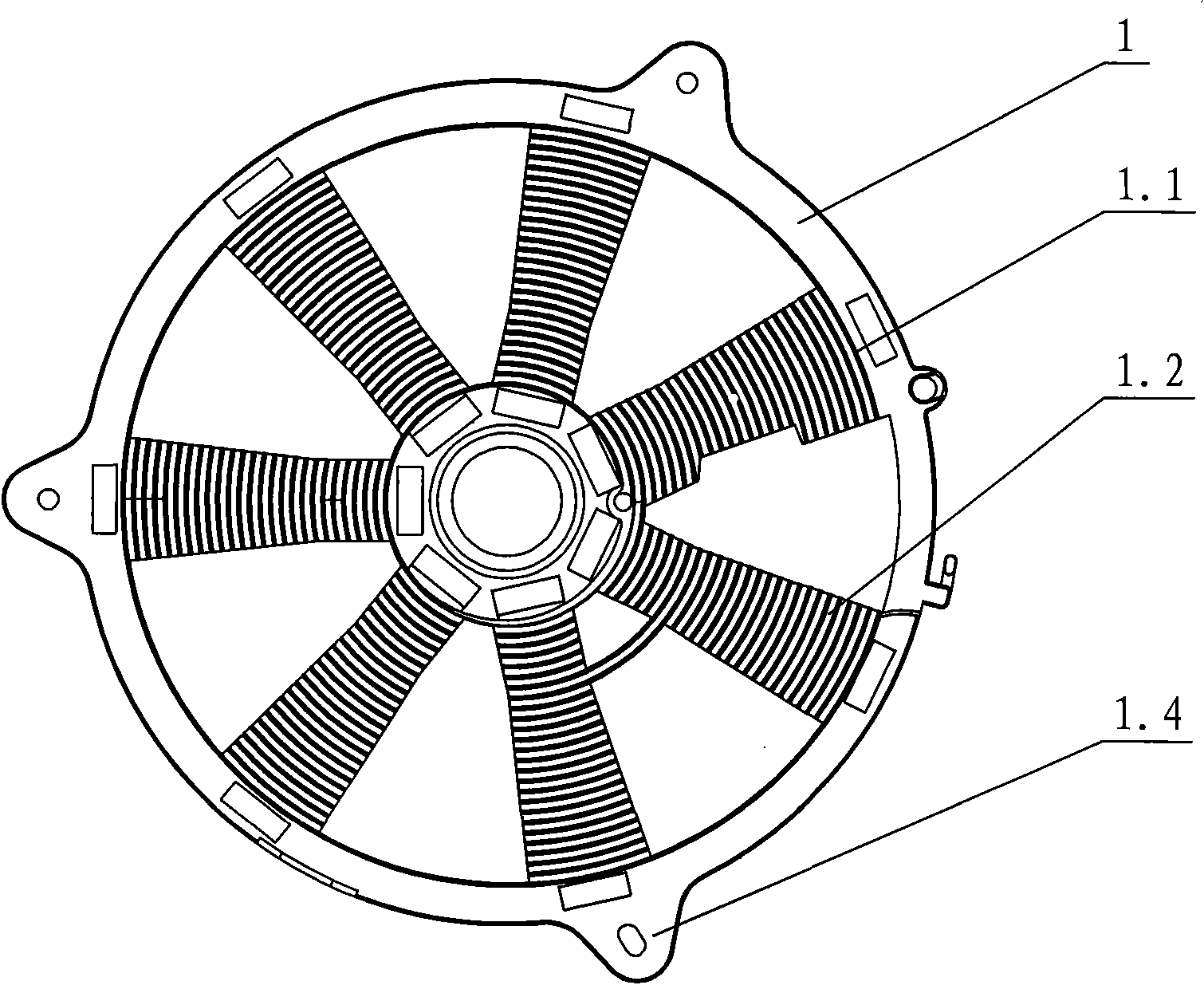

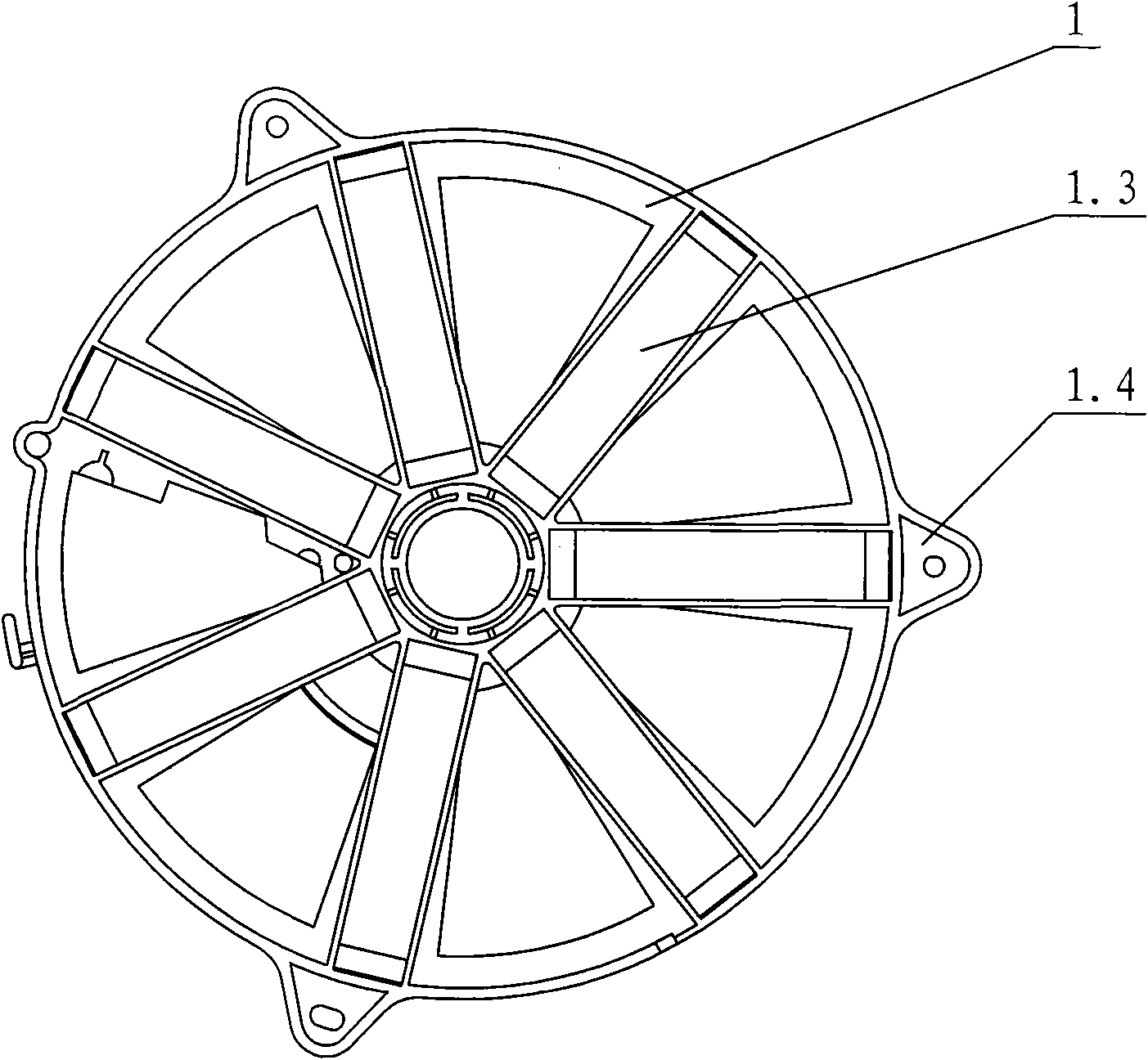

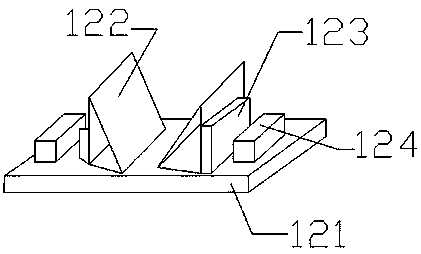

Electromagnetic oven wire coil, processing method thereof and hot-press forming device

ActiveCN101815375AShorten the timeReduce manufacturing costDomestic stoves or rangesCoil arrangementsEngineeringInduction cooking

The invention relates to an electromagnetic oven wire coil, a processing method thereof and a hot-press forming device. The electromagnetic oven wire coil comprises a wire spool made of fire resistant thermoplastic material, a coil and a coil groove wound at the top and a magnetic strip channel with a magnetic strip at the bottom, the coil is directly fixed by pressurizing and thermally melting the edge material of the coil groove; the wire spool is provided with a support rib, the coil groove is arranged on top of the support rib, and the magnetic strip channel with the magnetic strip is arranged at the bottom, and at least two ear clips are also arranged at the periphery of the wire spool. The material of the coil groove, which is higher than the coil part, is hot-pressed and deformed by the hot-press forming device and covers the top of the coil so that the coil is tightly pressed in the coil groove. In the invention, the coil or / and the magnetic strip is fixed by a hot-press die controlled by the hot-press forming device to greatly shorten the time for fixing the coil and the magnetic strip on a traditional electromagnetic oven wire coil, greatly improve the production efficiency and the rate of good products and greatly decreases the production cost of enterprises.

Owner:FOSHAN SHUNDE CHANGXING ELECTRONICS MFR

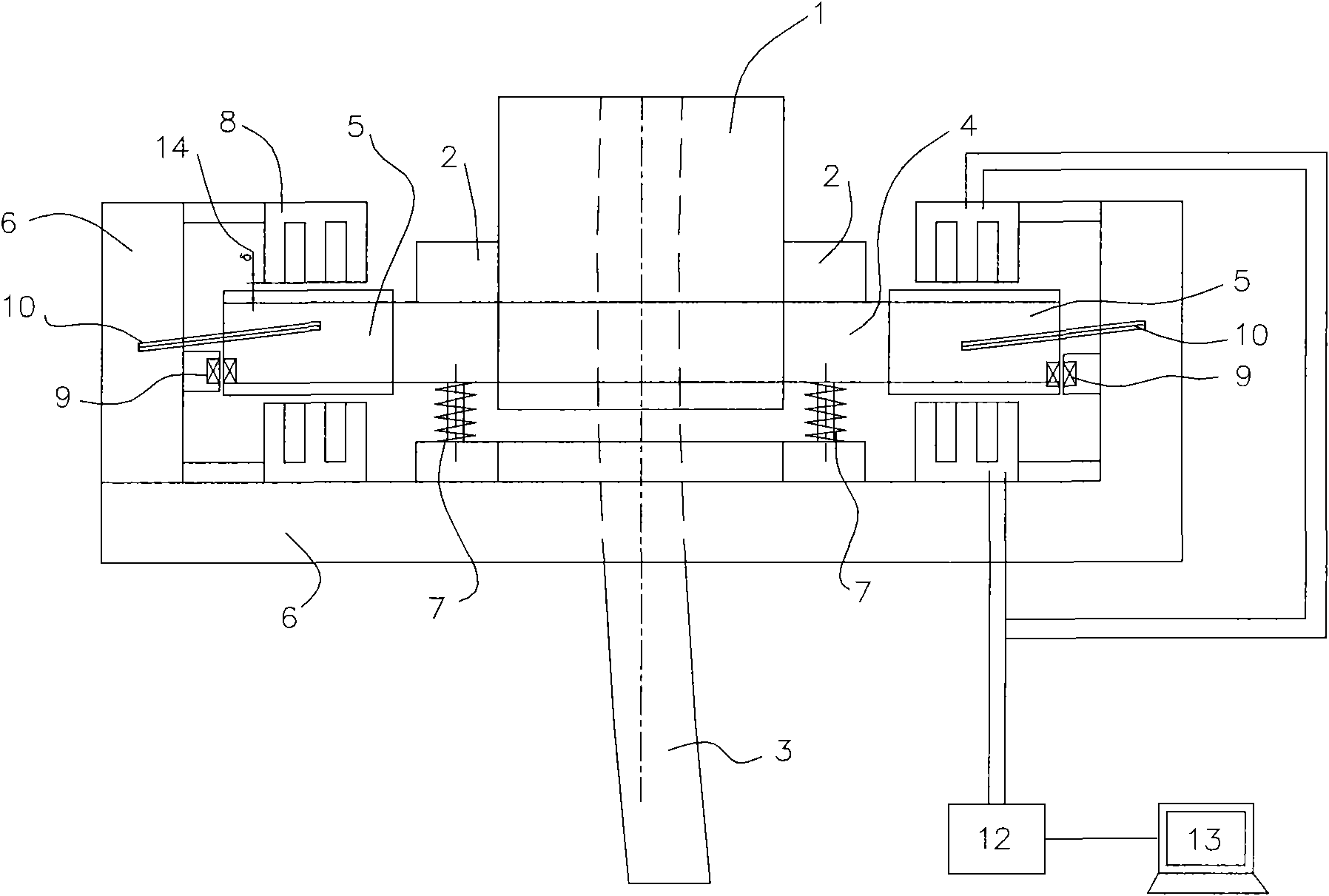

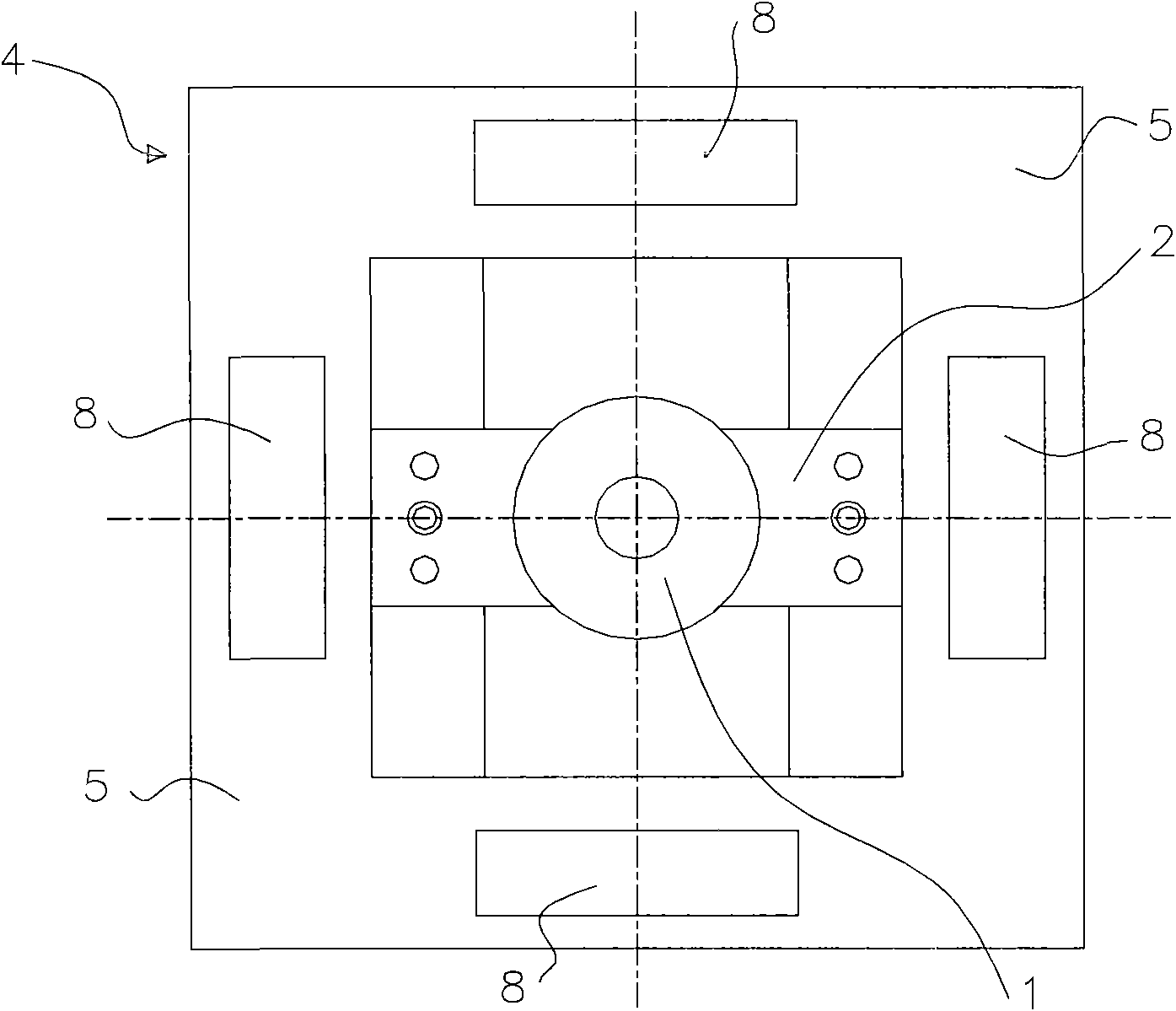

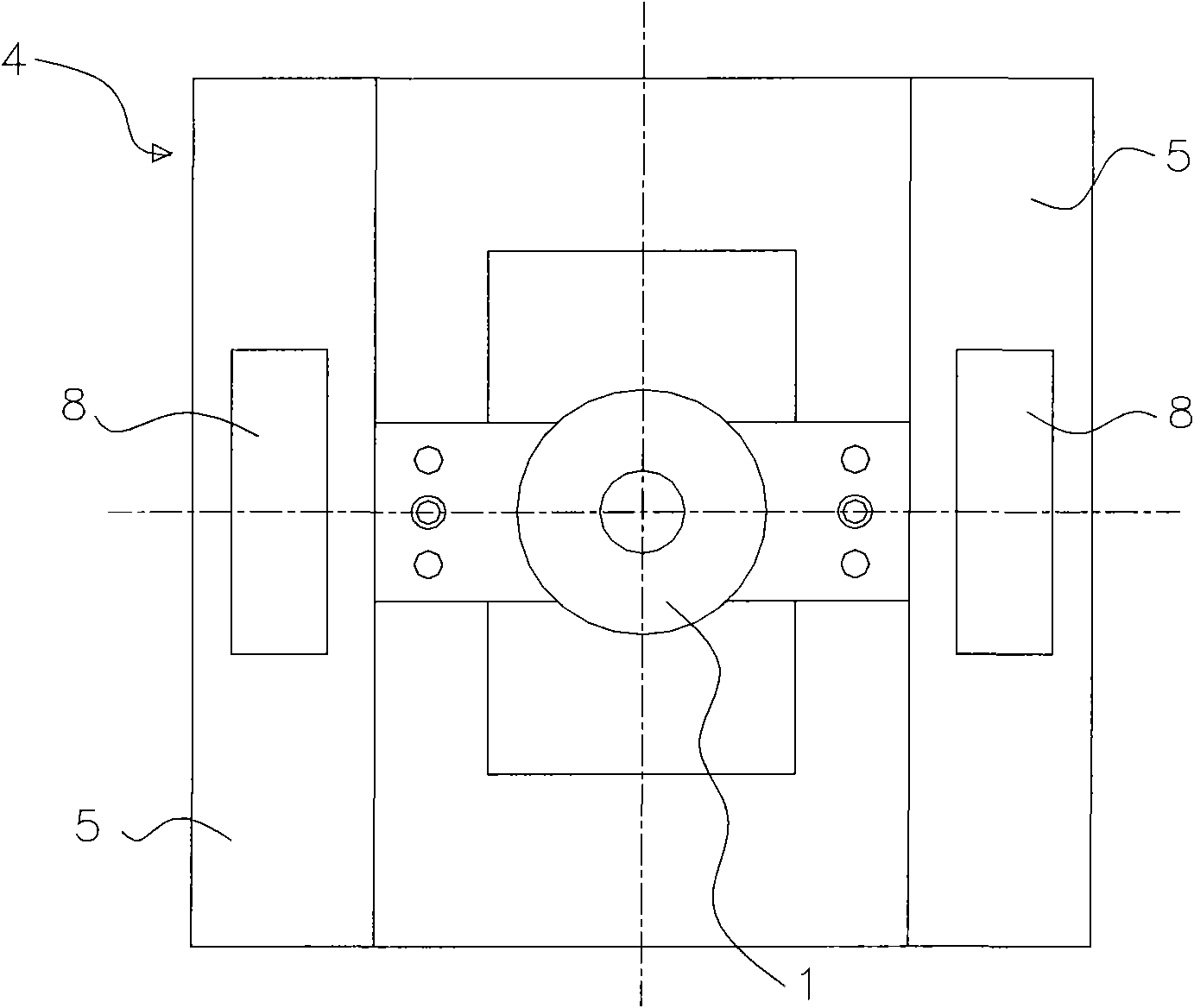

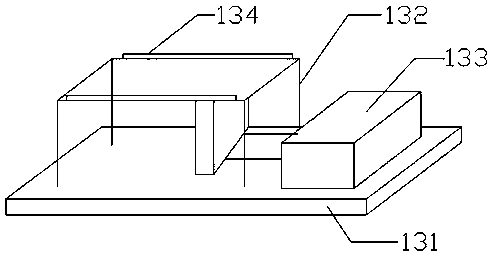

Multi-waveform electromagnetic excitation device of continuous casting crystallizer

ActiveCN102139357AReduce consumptionHigh vibration precisionComputer control systemAudio power amplifier

The invention discloses a multi-waveform electromagnetic excitation device of a continuous casting crystallizer, wherein a crystallizer extension end (2) of the multi-waveform electromagnetic excitation device is fixedly arranged on a movable frame (4); the movable frame is arranged at a fixing frame (6) through an elastic support assembly; the upper side and the lower side of the periphery of the movable frame are equipped with a plurality of armature iron mechanisms (5); a plurality of groups of coupled suspension electromagnets (8) are arranged on the fixing frame; the suspension electromagnets are vertically arranged and vertically correspond to one armature iron mechanism; the suspension electromagnets are connected with a power amplifier (12) through cables; a computer control system (13) is connected with the power amplifier to differentially control the suspension electromagnets in couples; and a guide-plate spring (10) is arranged between the side face of the movable frame and the fixing frame to ensure that the crystallizer (1) fixedly arranged on the movable frame can be vibrated in an arc shape according to a continuous casting arc line. In the invention, the coupled differential suspension electromagnets are controlled through the computer control system; the forced vibration of arbitrary waveforms of the crystallizer can be realized; and the vibration precision of the continuous casting crystallizer can be enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

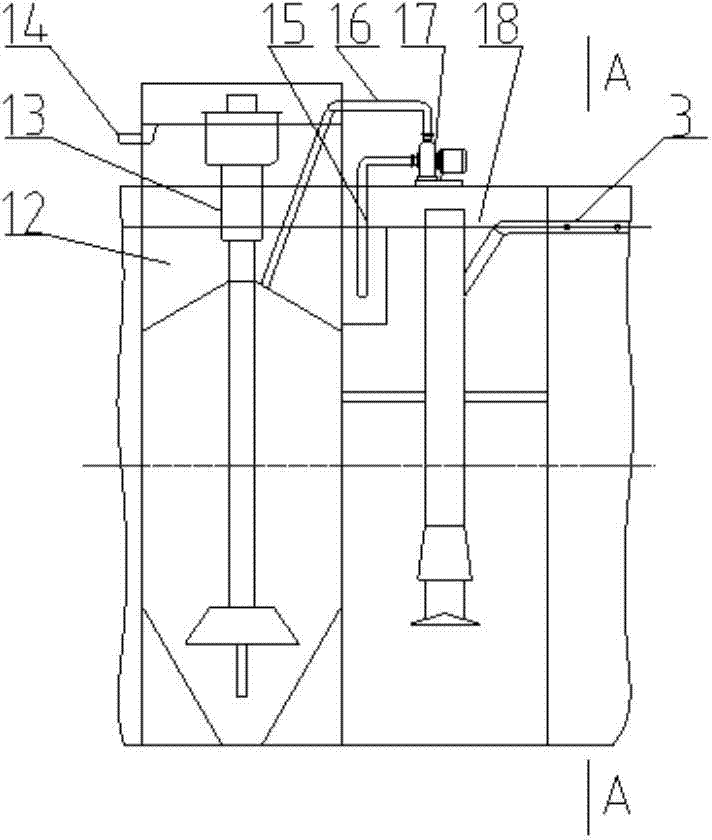

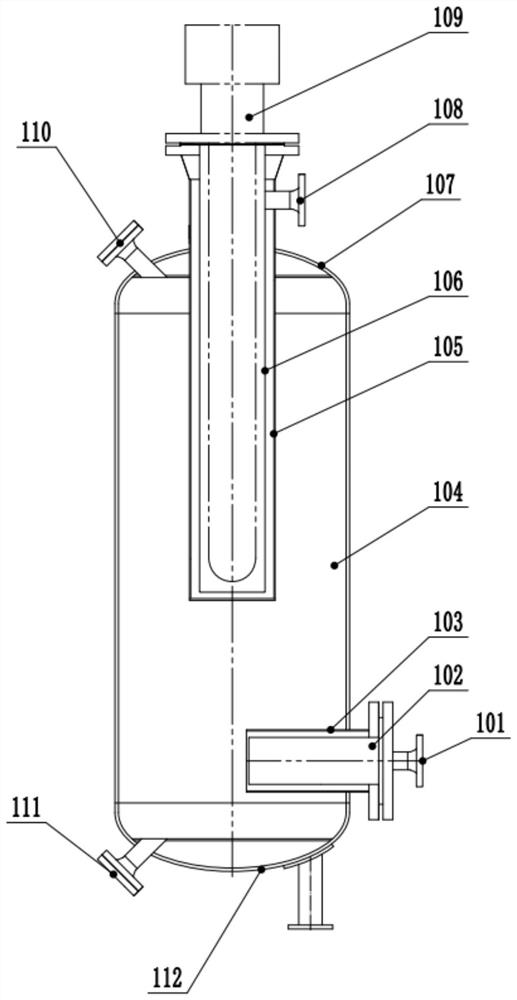

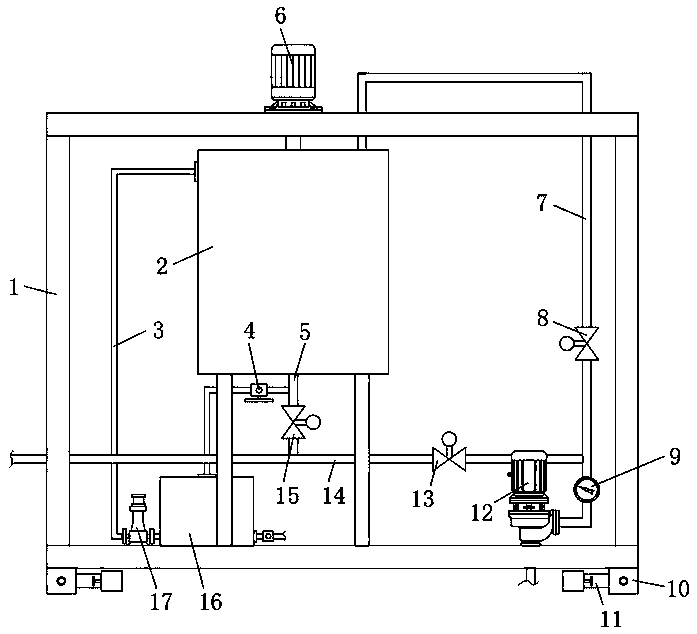

Natural gas heating and regeneration integrated dehydration device and method

PendingCN114231327ASatisfy the function of zero emissionMeet the requirements of transportationGas treatmentDispersed particle filtrationAir compressionVapor–liquid separator

The invention relates to a natural gas heating and regeneration integrated dehydration device and method, the device comprises an inlet filter (1), a first dehydration tower (2), a second dehydration tower (6), an outlet filter (3), a circulating compressor (4), a gas-liquid separator (5) and a cooler (7), and the first dehydration tower (2) and the second dehydration tower (6) are switched for adsorption and regeneration. According to the device disclosed by the invention, the heater and the drying tower are designed in a built-in manner, the inlet and the outlet of the tower adopt a filter element form and can be randomly disassembled, assembled and replaced, the structure meets a larger flow area, the device does not need an additional instrument air compression system, air filtered at the inlet can meet instrument air source conditions, energy consumption is avoided, and the gas quality is clean.

Owner:XINDI ENERGY ENG TECH

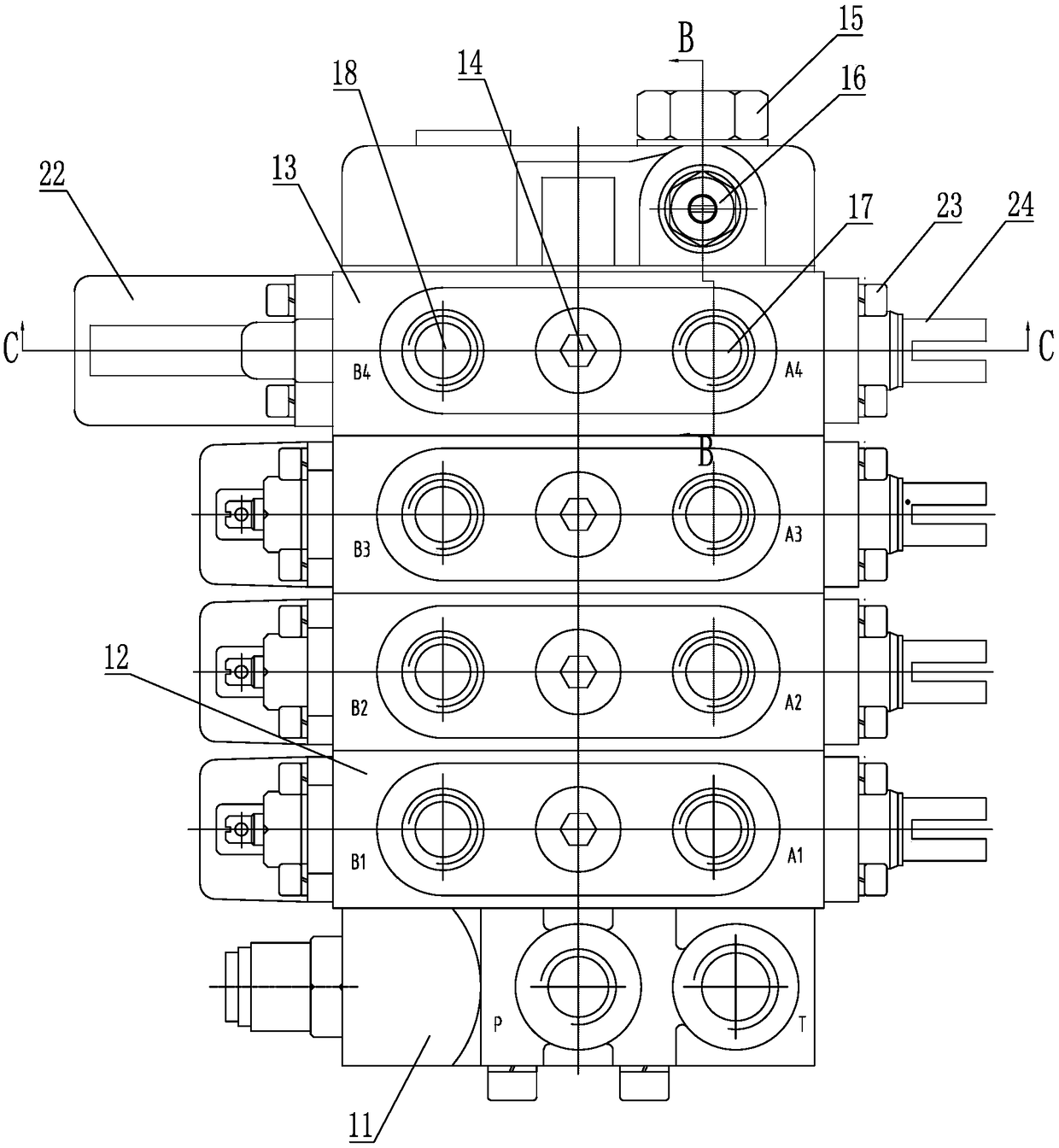

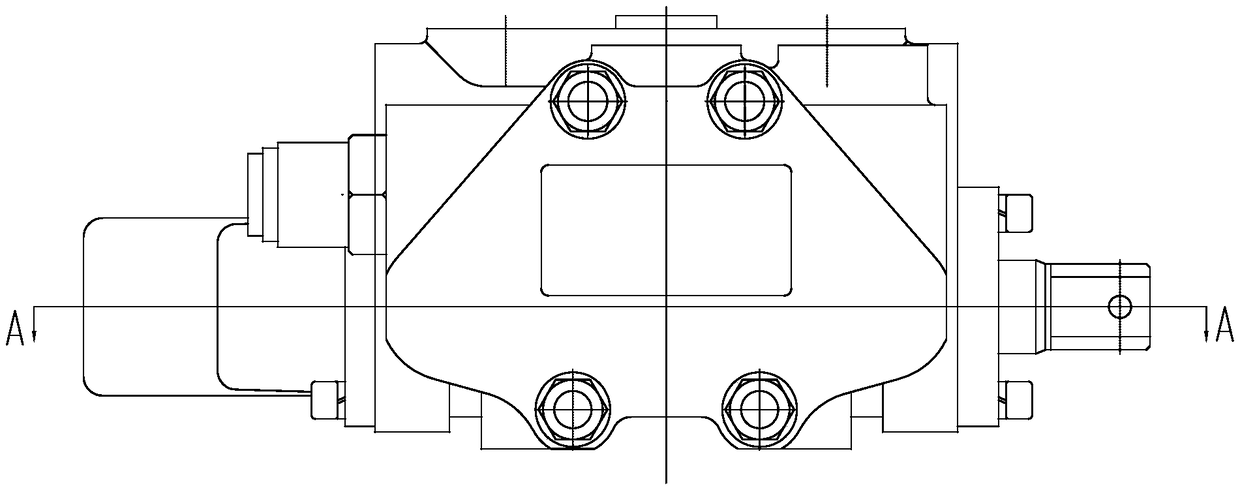

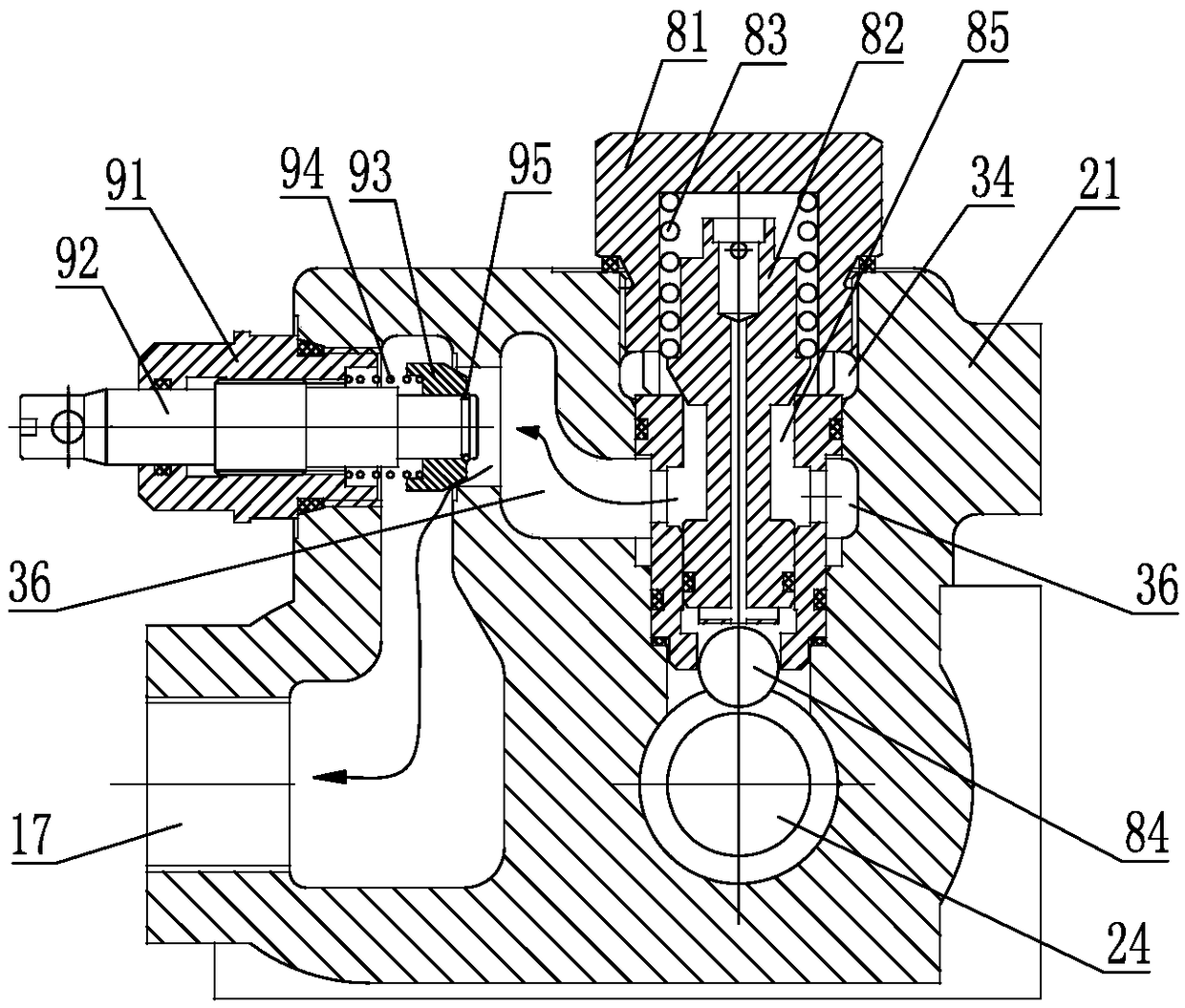

Multi-way valve for tractor and integrated with auto-skip distributor function

PendingCN109162979AReduce pipelineEliminate the problem of unequal area of return oil back pressureServomotor componentsCheck valvesDistribution controlEngineering

The invention discloses a multi-way valve for a tractor and integrated with an auto-skip distributor function. The multi-way valve comprises an oil inlet body, and the oil inlet body is provided withan oil inlet P and an oil returning opening T. A plurality of working valve plates are connected in parallel on the oil inlet body in sequence, and the outermost working valve plate is connected witha distribution control valve. The distribution control valve includes a valve body, and a valve rod is installed in the valve body. A skip adjustment device is installed in the inner cavity of the valve rod, and a set screw for blocking the inner cavity of the valve rod is installed at the end of the valve rod. A valve rod positioning device is installed between the valve rod located between the set screw and the skip adjustment device, and a valve rod reset device is installed between the set screw and the valve rod positioning device. The multi-way valve is compact in structure, lightens theweight, saves pipelines between the multi-way valve and a distributor, and is convenient to install, arrange and maintain; and the skip adjustment device eliminates the problem of unequal return oilback pressure acting areas on a valve rod assembly system, so that the valve rod has automatic skip of secondary pressure in the strong-lifting position, and simplicity and reliability are achieved.

Owner:青州博信华盛液压科技有限公司

Automatic construction rebar bending mechanism

The invention provides an automatic bending mechanism for building steel bars, which includes a feeding device, a cutting device, a steel bar bending device, and a receiving bin arranged on the front side of the steel bar bending device; the steel bar bending device includes a Feeding device, the bending device on the right side of the feeding device; the feeding device includes a gantry, a silo, a feeding lifting component, and a feeding pushing component; the bending device includes a bending frame, a bending component, and a bending component for matching Auxiliary parts for bending steel bars; auxiliary parts include a material plate, a plurality of bending parts, a discharge power assembly arranged on the side of the material plate and a horizontal moving assembly for adjusting the position of the material plate; the invention has a simple structure , other processes can continue to work when the steel bar is bent; multiple automatic bending of the steel bar material can be realized, and the bending angle of the steel bar material can be adjusted at any time; the bent steel bar material is pushed to the receiving bin through the discharging power component , shorten the processing time and improve work efficiency.

Owner:郑州众益德网络科技有限公司

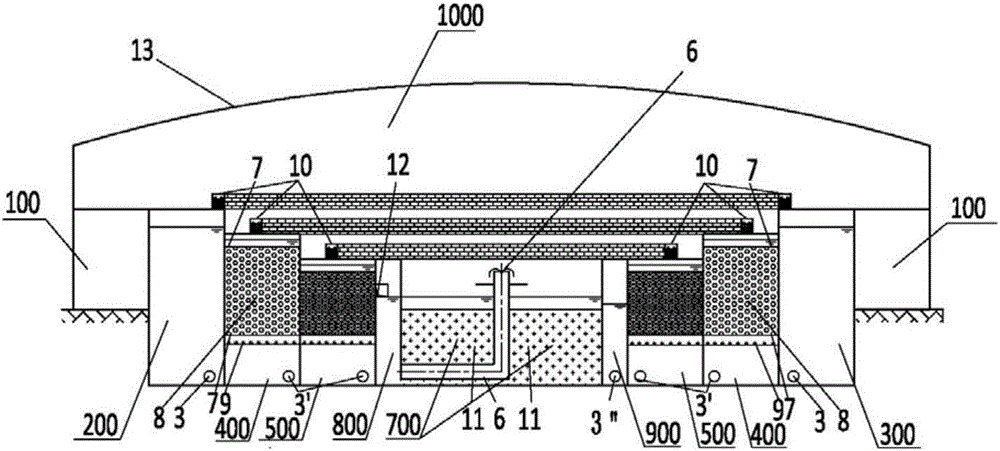

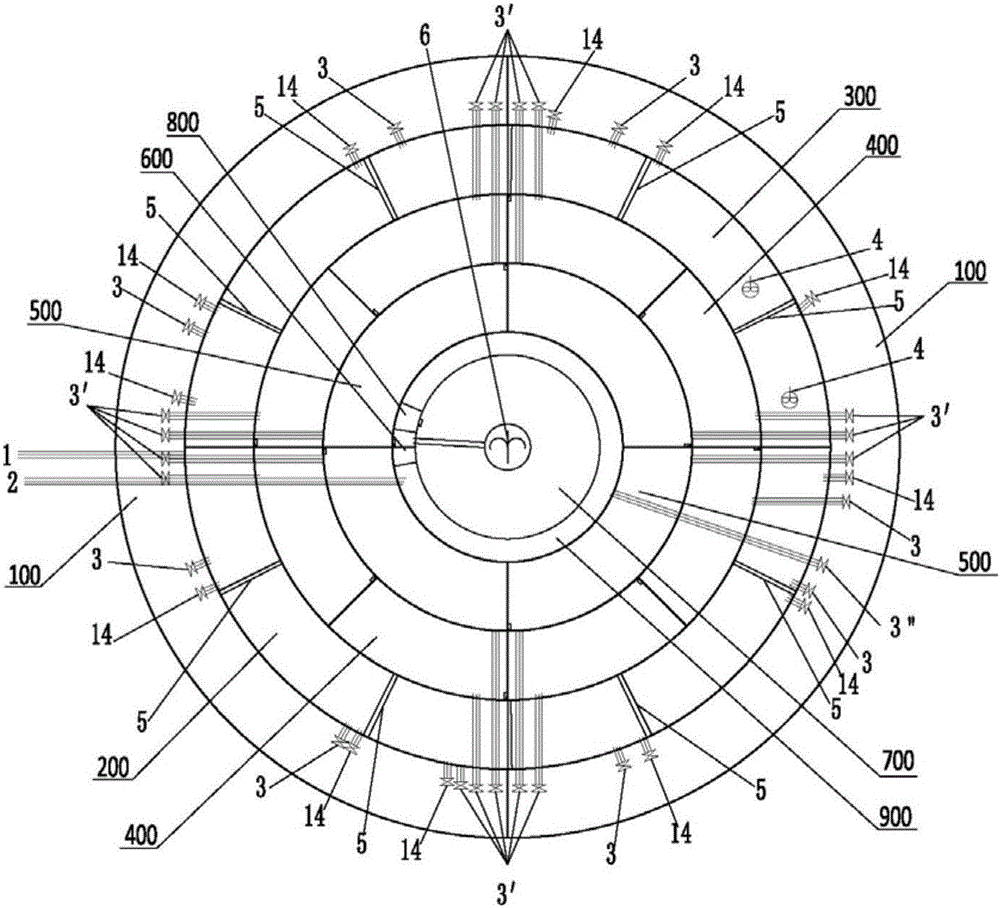

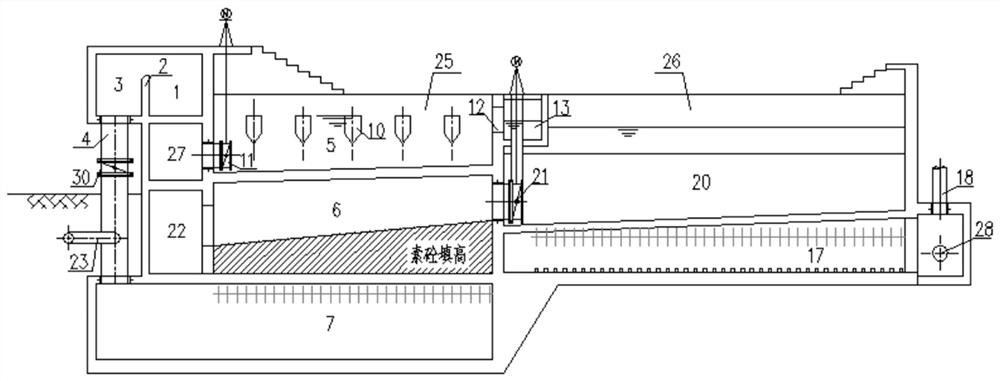

Ecological peristalsis bed reactor and method using same to treat waste water

ActiveCN105668937AInhibit swellingAvoid it happening againFatty/oily/floating substances removal devicesSpecific water treatment objectivesSludgeLandscaping

The invention relates to an ecological peristalsis bed reactor. The ecological peristalsis bed reactor comprises an equipment room unit, a greenhouse unit, a primary pretreating unit, a secondary biological treating unit and a tertiary deep treating unit, wherein an oil-insulation sedimentation area and a coagulation sedimentation area, a water pipe, an oil discharge pipe and a first sludge discharge pipe are arranged in the primary pretreating unit; a biological carrier, an aeration system, a first sludge sedimentation area and a second sludge discharge pipe are arranged in the secondary biological treating unit; a plant absorption area, a sterilizing area, a second sludge sedimentation area and a third sludge discharge pipe are arranged in the tertiary deep treating unit. To-be-treated waste water can reach the first-grade A standard after being treated by the primary pretreating unit, the secondary biological treating unit and the tertiary deep treating unit. The ecological peristalsis bed reactor has the advantages that a greenhouse is mounted at the top of a treating area, special aquatic plants are planted in the plant absorption area, aisle flower beds are designed, the temperature in the greenhouse is kept, linkage treatment by microorganisms and the plants is achieved, and integration, automation, deodorization and landscaping of waste water treatment are achieved.

Owner:北京中淏环保科技有限公司

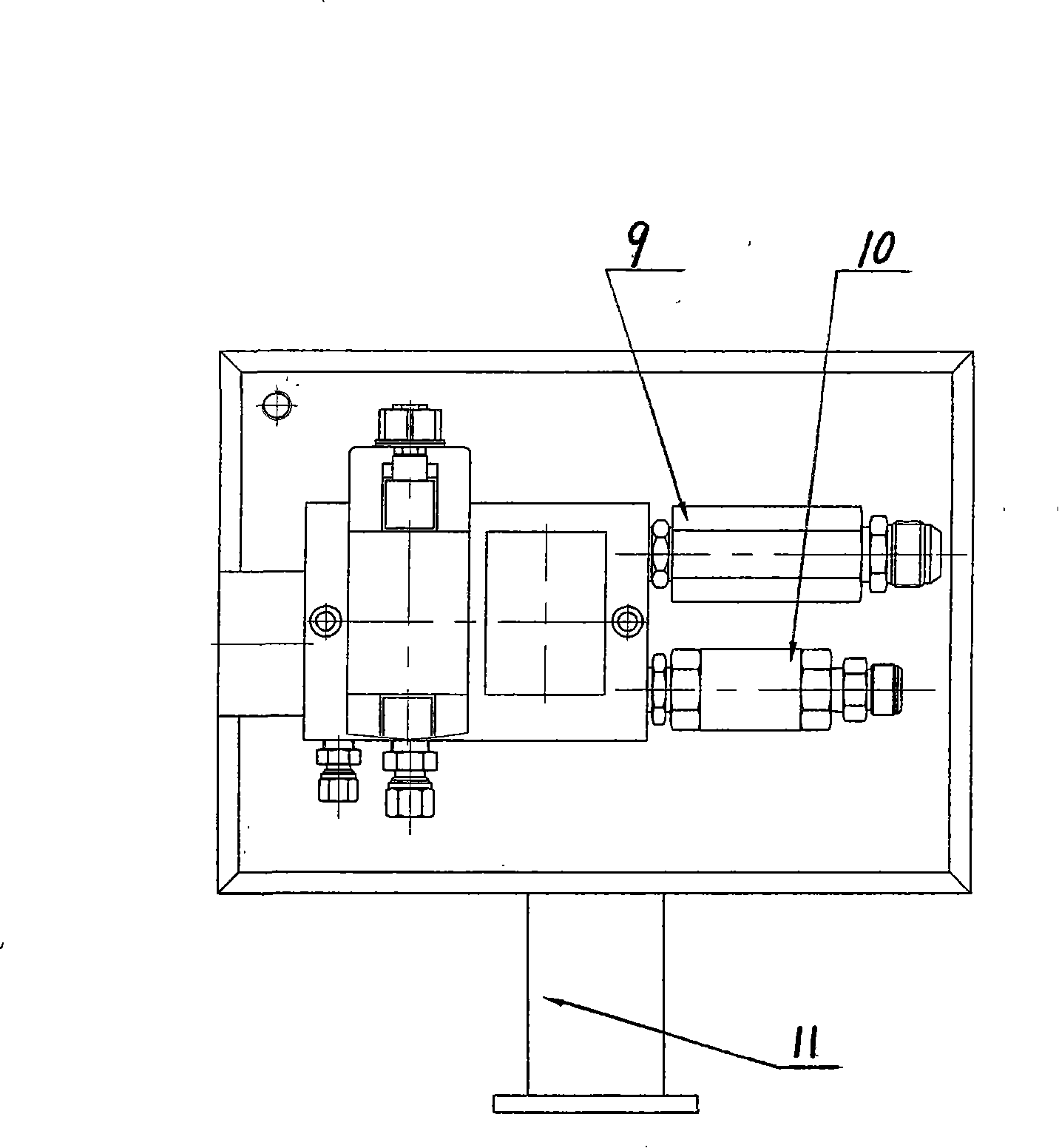

Novel hydraulic motor transmission control valve group

InactiveCN101251133AReduce energy consumptionReduce pipelineServomotor componentsHydraulic motorControl valves

The invention discloses a novel hydraulic motor transmission control valve bank which comprises an electromagnetic directional valve, a one-way throttle valve, a shuttle valve, an overlapped valve, a one-way valve and a ball valve, wherein each control valve is arranged on a junction valve block; a braking oil cylinder control valve adopts a shuttle valve built-in type two-way cartridge valve cover board; the junction valve block is arranged on the upper part of a drip pan; the inside of the junction valve block has a plurality of channels and oil holes; moreover, one side of the drip pan is provided with a fixing device. The novel hydraulic motor transmission control valve bank which has a simple structure can be arranged near the transmission device of a hydraulic motor, thereby reducing pipes and energy consumption.

Owner:康凤明

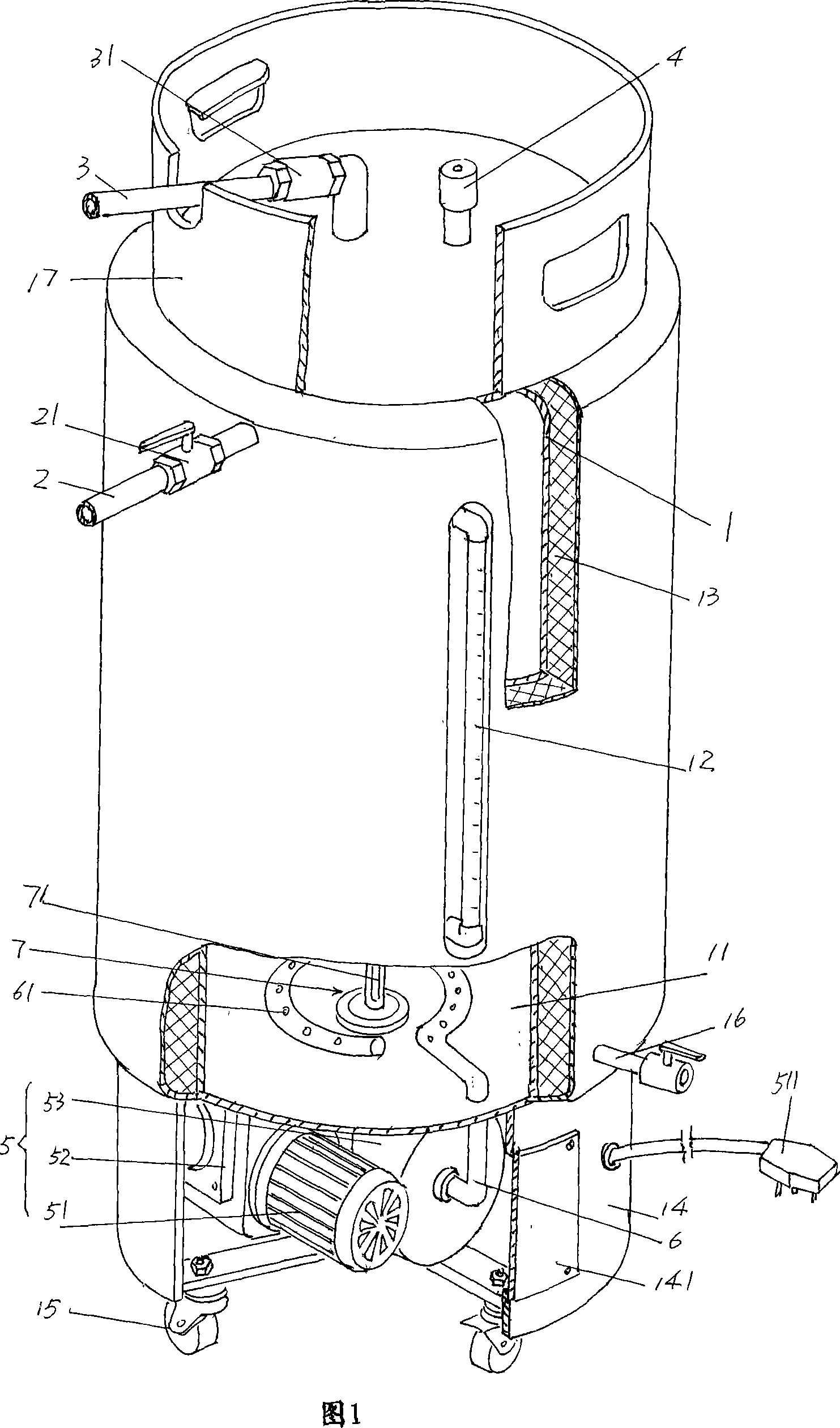

Liquid C5 vaporisation apparatus

InactiveCN101059204AInsulation helpsMobile saves effortContainer filling methodsPressure vesselsLiquid stateCombustible gas

A liquid C 5 gasification device gasifies liquid C 5 as fuel into the gas which can be used in the site needing a great amount of combustion. It includes a tank with tank cavity; a feeding interface is linked with tank and connected with the tank cavity and used for transmitting liquid C 5 raw material for gasifying into the tank cavity; one gas guiding interface is linked with tank and connected with the tank cavity and used for leading the gasified combustible gas out in the tank cavity; one snuffle valve is installed on the tank and used for releasing the pressure in tank cavity; one gas generating device; one vent pipe is used for leading the gas generated by the gas generating device into the tank cavity, one end of it is connected with the gas generating device and another end is inserted into the tank cavity. The advantages: less pipes; concise overall structure; it can control the feeding amount; energy-saving and improving gasifying effect; it is helpful for the gas generating device on the bottom of tank; the moving of tank is labor-saving; accommodation area-saving; it can ensure the tank cavity not plot sewage and can meet the gasifying requirement when the winter environmental temperature is lower than 14 deg.C.

Owner:何小华

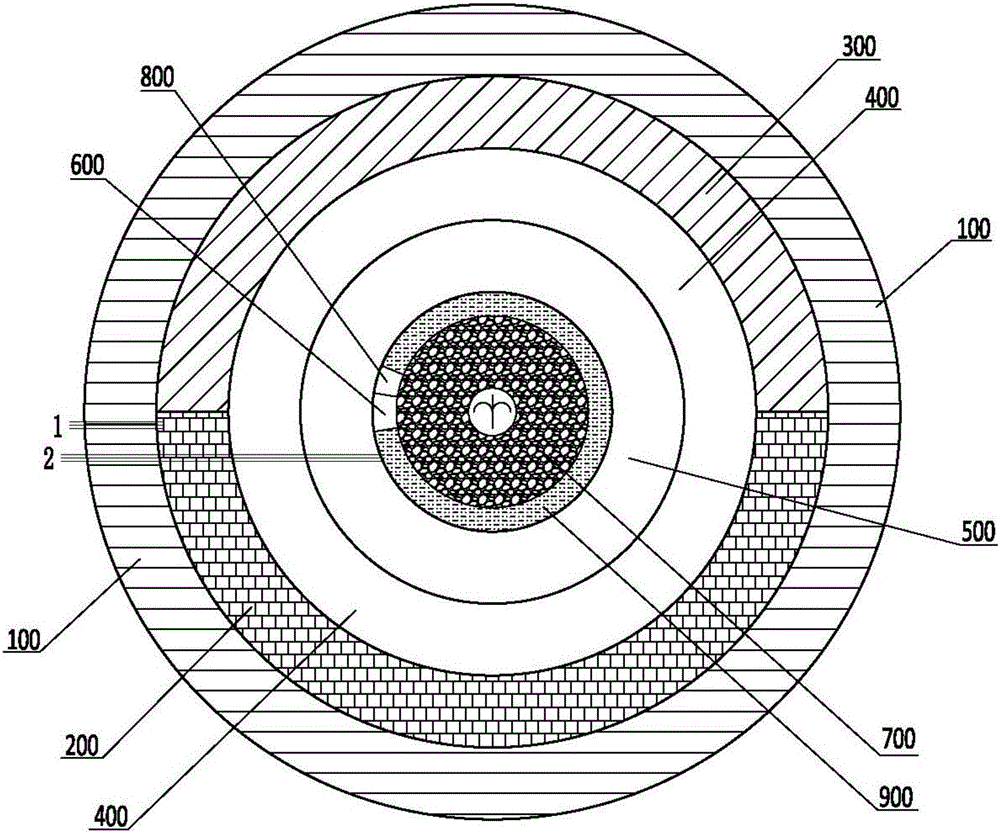

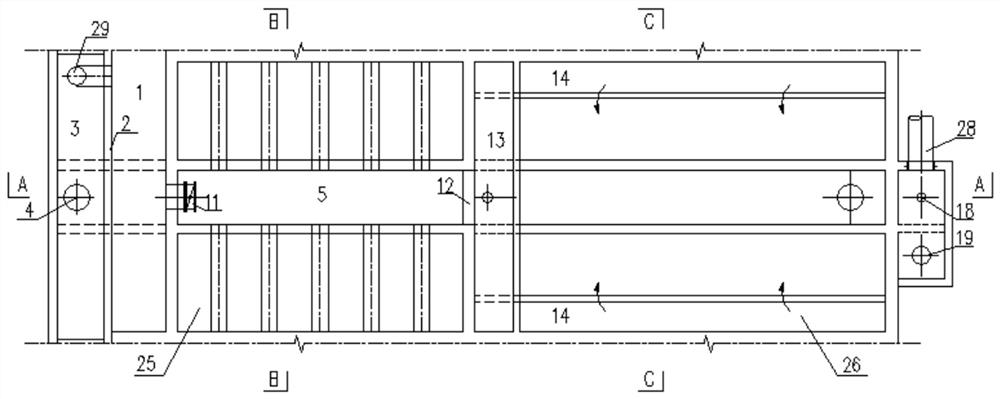

Carbon-sand double filter tank with central canals

PendingCN112408617AReduce lossesSimple structureSpecific water treatment objectivesTreatment involving filtrationActivated carbonSmall footprint

The invention provides a carbon-sand double filter tank with central canals. Three layers of central canals, namely an upper-layer produced water drainage channel, a middle-layer sand tank drainage channel and a lower-layer carbon tank water inlet channel, are arranged in the center of a carbon tank, and the lower-layer carbon tank water inlet channel is also used as a back-washing gas distribution channel; two layers of central channels, namely an upper-layer drainage channel and a lower-layer back-washing water and gas distribution channel, are arranged in the center of a sand tank; and thecarbon tank and the sand tank are separated by a partition wall and are communicated only through upper-layer water passing holes of the central channels. After entering, the water to be treated is treated by an upward flow activated carbon adsorption tank, then enters the sand tank from the water passing holes in the partition wall, is filtered in the sand tank and then is discharged. The carbon-sand double filter tank with central canals provided by the invention is reasonable and feasible in tank type combination, compact in arrangement, simple in structure, low in manufacturing cost, few in pipelines and small in occupied area.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

High-power fuel cell and vehicle-mounted hydrogen integration system and method

The invention provides a high-power fuel cell and vehicle-mounted hydrogen integration system and method. The high-power fuel cell and vehicle-mounted hydrogen integration system comprises a vehicle-mounted hydrogen supply subsystem, two sets of fuel cells, a heat dissipation assembly, a DC / DC module and an air filter, the vehicle-mounted hydrogen supply subsystem is respectively connected with the two sets of fuel cells and respectively provides hydrogen for the two sets of fuel cells; the heat dissipation assembly is attached to the two sets of fuel cells and is used for dissipating heat of the two sets of fuel cells respectively; the output ends of the two sets of fuel cells respectively supply power to the vehicle through the DC / DC module; the air input ends of the two sets of fuel cells are respectively connected with outside air through an air filter, and the exhaust ends of the two sets of fuel cells are respectively connected to the atmosphere through exhaust pipelines. The system can monitor the running state of the fuel cell and the state of the hydrogen cylinder, and if leakage occurs, a driver can be reminded of the hydrogen leakage state. A driver can be reminded of the collision state of the hydrogen cylinder; the stable operation of the system is ensured, and the safety of the large commercial vehicle is further ensured.

Owner:SINO TRUK JINAN POWER

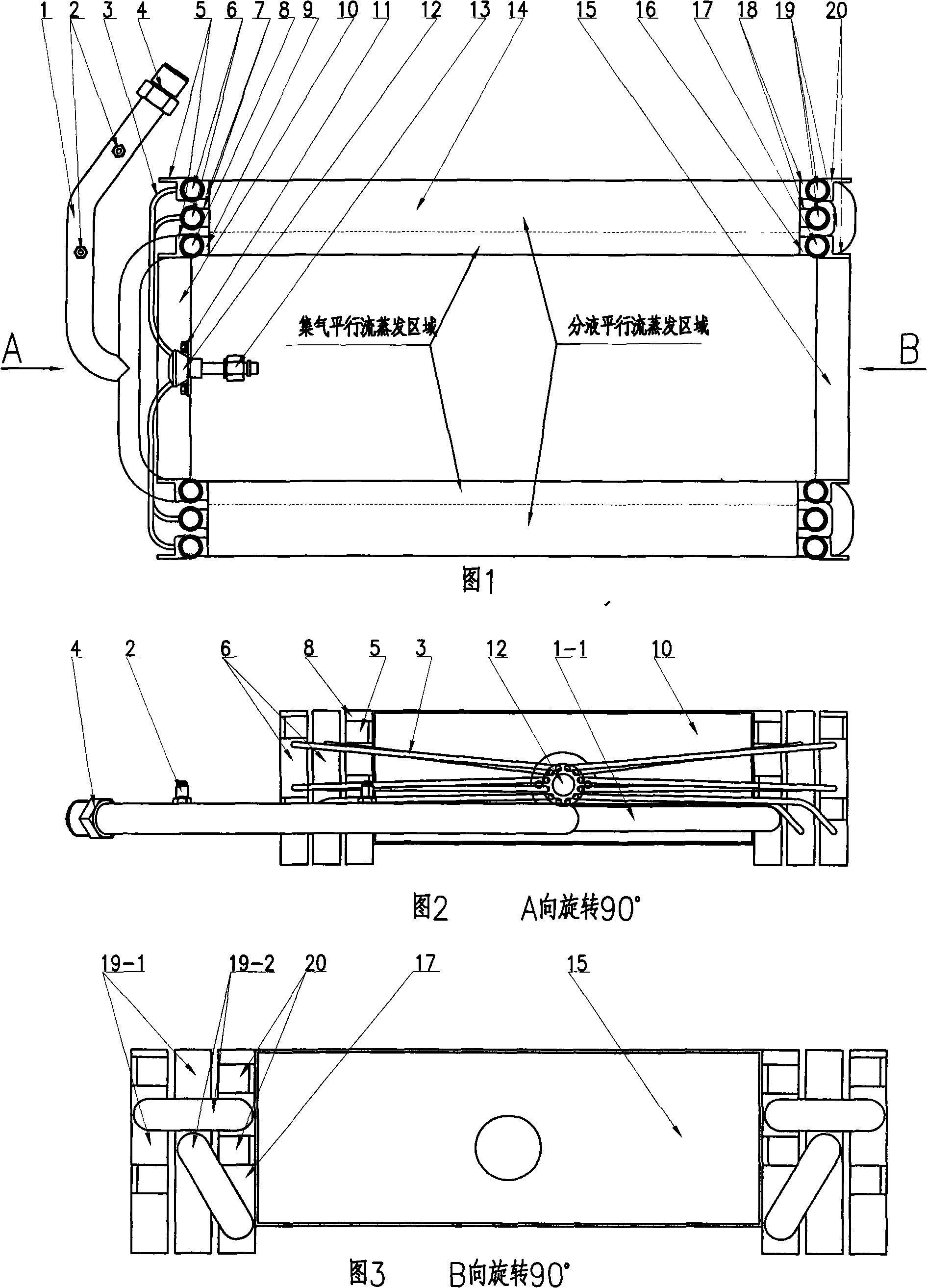

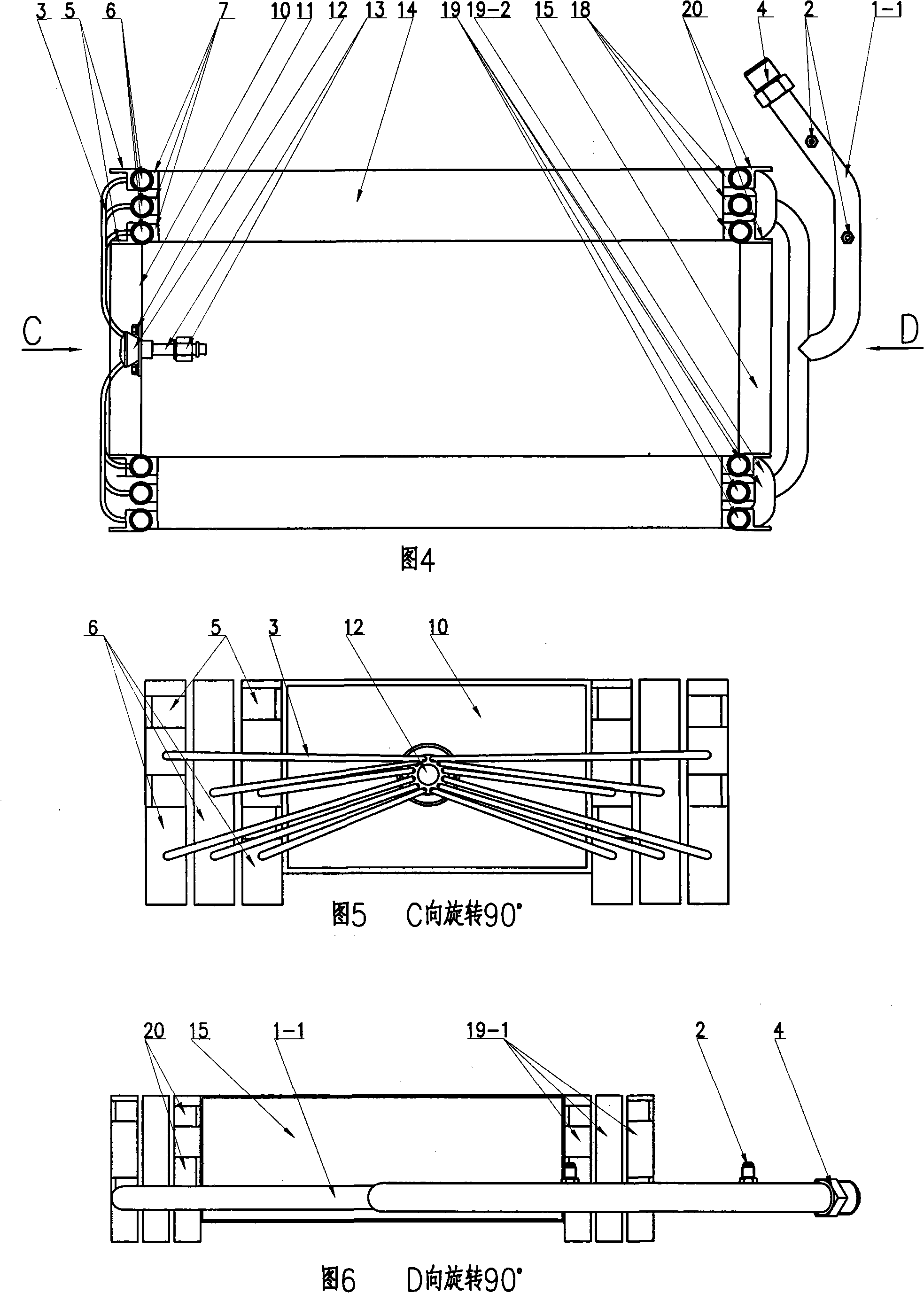

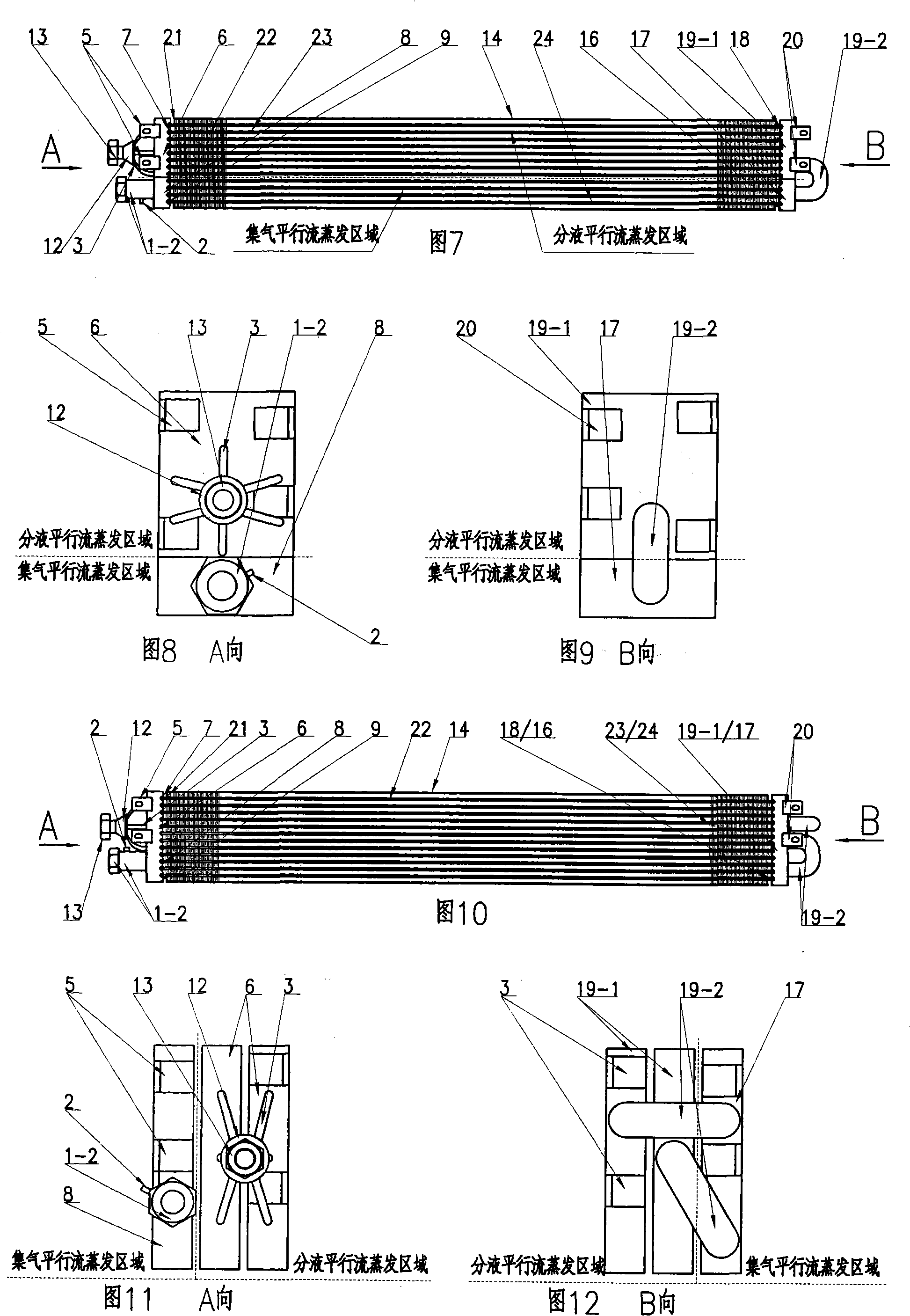

Parallel flow evaporator core structure

InactiveCN101493272AReduce pipelineImprove cooling effectEvaporators/condensersEvaporationEconomic benefits

The invention provides a parallel flow evaporator core structure. A single parallel flow evaporator core thereof is equipped with a radiator, a tritorium, a gas collector and a reverse communicating gas separating tank and a return pipe and also uses a thin-wall parallel flow pipe band; a parallel type parallel flow evaporator core is formed by integrating a plurality of single parallel flow evaporator cores. Full liquid separation-gas collection, non-reverse parallel circulating refrigerant can be carried out in a full liquid separation parallel flow evaporation area, or, liquid separation-gas collection and gas separation-gas collection, reverse refrigerant circulating among parallel flow evaporating areas by the reverse communicated gas separating tank can be carried out in liquid separating parallel flow evaporating area and gas collecting parallel flow evaporating area according to the collecting-separating ratio. The invention effectively shortens the pipeline of the circulating refrigerant, increases the pipeline number, total cross sectional area and gross evaporation area of the circulating refrigerant, thus obviously improving the evaporation efficiency and reducing the production cost and energy consumption for the evaporator core. The technique scheme not only can further improve and upgrade the air conditioner evaporator technology and product, but also can improve economic benefit and save energy.

Owner:HANGZHOU SUNHOLD INDAL

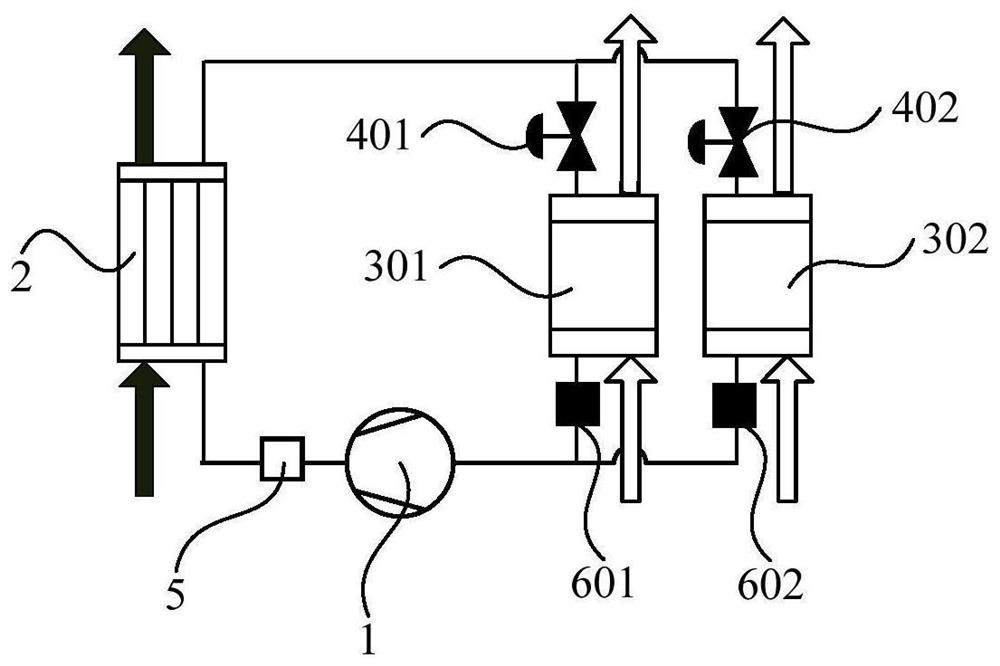

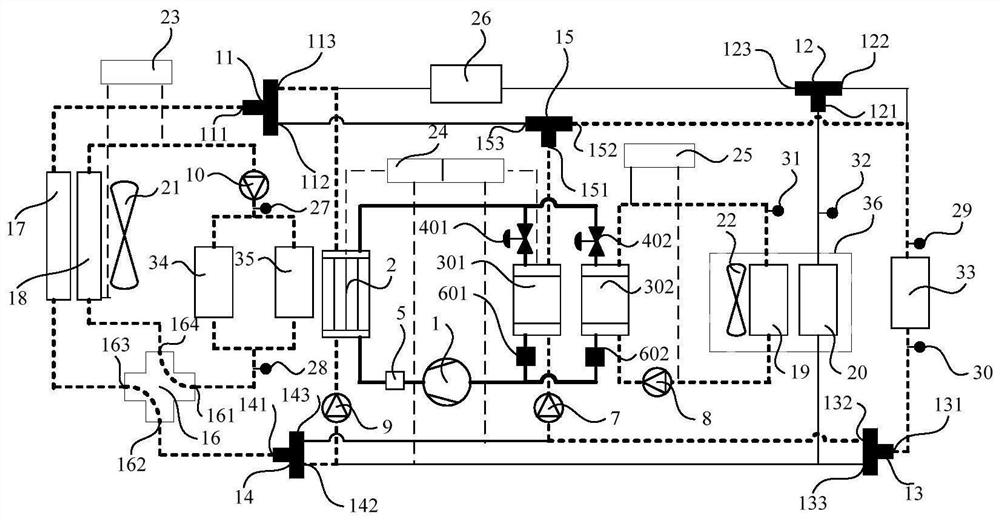

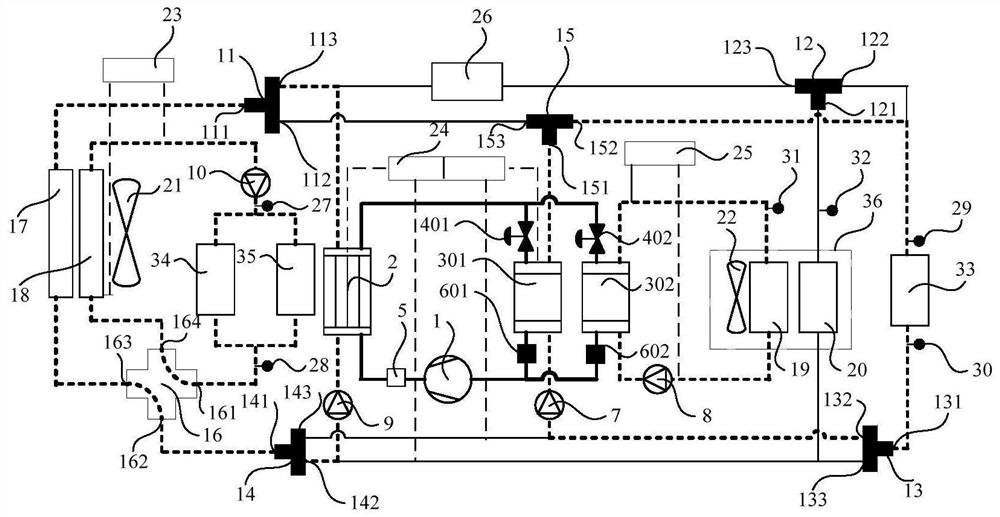

Refrigerant heat management module, heat management system and vehicle

PendingCN113547888ASimple control logicReduce pipelineAir-treating devicesElectric propulsion mountingPlate heat exchangerHeat management

The embodiment of the invention provides a refrigerant heat management module, a heat management system and a vehicle. By means of the mode that parts in the refrigerant heat management module are arranged in a centralized mode, pipelines for connecting the parts are shortened, the refrigerant flowing resistance is reduced, the working performance of a refrigerant loop is improved, and platform design is achieved through the modular design mode. Besides, the function of refrigerating the vehicle function module is achieved in the mode that a plate heat exchanger in the refrigerant loop absorbs heat from a cooling liquid loop of the vehicle function module, and the function of refrigerating the vehicle function module is achieved; in the mode that a condenser in the refrigerant loop releases heat to the cooling liquid loop of the vehicle function module, the function of heating the vehicle function module is achieved, whether the vehicle function module needs to heat or refrigerate, refrigerant flow in the refrigerant heat management module keeps circulation in the same direction, reversing is not needed, and the control logic of the refrigerant heat management module is greatly simplified.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Simple and accurate water metering device

PendingCN110497527AThe overall structure is simpleReduce pipelineHollow article cleaningLiquid ingredients supply apparatusA-weightingEngineering

The invention discloses a simple and accurate water metering device, and relates to the technical field of water metering devices. The simple and accurate water metering device comprises a frame body,a liquid storage tank and a water pump, wherein the liquid storage tank and the water pump are arranged inside the frame body, the water pump is located on one side of the liquid storage tank, the water pump is connected with the liquid storage tank through a first conveying pipe, and the side, close to the water pump, of the first conveying pipe is provided with a flow meter. According to the device, one solenoid valve and a weighting sensor of a container are omitted, so that the overall structure of the device is simple, pipelines are reduced, installation is facilitated, the installationefficiency of the device is greatly improved, and the cost is reduced at the same time; in addition, metering is carried out only through the flow meter, the weighing sensor is not needed, so that theflow meter can accurately measure, and the metering precision of the device can be conveniently improved; and meanwhile, a control circuit does not need the weighing sensor, so that fault points arereduced, and the reliability of the whole system is greatly improved.

Owner:QINGDAO DEX MACHINERY

Fluid control assembly

ActiveCN113175768ASmall flow resistanceReduce pipelineMechanical apparatusEvaporators/condensersFluid controlHeat management

The invention discloses a fluid control assembly. A fluid switching device comprises a base part and a switching part, the switching part is arranged in the base part, the switching part can switch the communication relation of a first connector, a second connector, a third connector, a fourth connector and a fifth connector, and a flow dividing part is an integrated piece. The flow dividing part and a main body part are fixedly installed together or the flow dividing part and the main body part are an integrated piece, a fourth hole channel of the flow dividing part comprises a first sub-hole channel and a second sub-hole channel which are communicated with each other, the first sub-hole channel is communicated with the fourth connector, the second sub-hole channel is communicated with the fifth connector, and the fourth connector and the fifth connector are not communicated on the outer wall face of the base part. The fourth hole channel of the fluid switching device can be communicated with inner cavities of two other parts, the flow dividing part of the fluid switching device has the function of a three-way component, a pipeline of a heat management system can be shortened, and fluid flow resistance can be reduced.

Owner:SANHUA HLDG GRP

Hydraulic operation triple pump hydraulic system

ActiveCN101863421BReduce pipelineEliminate pressure shocksLoad-engaging elementsControl mannerControl valves

The invention relates to a hydraulic operation triple pump hydraulic system, which comprises a first oil pump, a second oil pump, a third oil pump, a rotary hydraulic system, a hoisting arm extension and retraction system, a safety unload hydraulic system, a lifting hydraulic system, a hoisting arm amplitude variation hydraulic system, a pressure reduction pilot oil source valve group and a control valve group, wherein the starting and closing characteristics of a rotary braking device, a main hoisting braking device and a sub hoisting braking device adopt the constant-pressure oil source control mode without additional external force operation, and the control on the braking devices can be intelligently and automatically realized according to the operation of each action. The invention realizes the fast-opening slow-closing control mode on a rotary structure and the slow-opening fast-closing control mode on main and sub hosting mechanisms according to different starting and closing characteristics of each mechanism, and effectively eliminates the pressure impact on the system. A flow distribution valve adopts the flow distribution mode irrelevant with a load, so slow action or noaction of executing mechanisms with high load pressure caused by pressure interference among all executing mechanisms can be effectively prevented. Each element in the whole vehicle system has high integration and modularization, and the maintenance is convenient.

Owner:卢宇

Gas inlet structure for pressure swing adsorption drying machine and nitrogen oxygen generator

PendingCN110526217ALow costEasy to produceNitrogen purification/separationSpecific gas purification/separationNitrogenInlet valve

The invention provides a gas inlet structure for a pressure swing adsorption drying machine and nitrogen oxygen generator. The gas inlet structure comprises a valve body, a first adsorption tank and asecond adsorption tank; a second cavity is arranged in the valve body; two ends of the second cavity respectively communicates with a first cavity and a third cavity; the middle part of the second cavity communicates with a gas inlet; a valve core is slidably arranged in the second cavity; the first cavity communicates with an inner cavity of the first adsorption tank; the third cavity communicates with an inner cavity of the second adsorption tank; the first cavity is connected in parallel with a first exhaust device communicating with the outside; and the third cavity is connected in parallel with a second exhaust device communicating with the outside. According to the invention, two gas inlet valves are reduced, so that cost is saved; production and manufacturing are simple, valve bodies are few, pipelines are few, installation is simpler, control is simpler, and only two valves need to be controlled; and the structure of the gas inlet structure is compact.

Owner:FOSHAN TIANDI YUANYI PURIFICATION EQUIP

Horizontal evacuating device

The invention relates to a horizontal vacuuming device, which belongs to the technical field of negative pressure generating devices in production of chemical products. The horizontal vacuuming device comprises a water tank, a water circulation mechanism, a spray head pipe, a return pipe and a vacuum connecting pipe, wherein the water circulation mechanism comprises a motor, a water pump matched with the motor, and water inlet and outlet pipes; one end of the water inlet pipe is connected with the water tank, while the other end is connected with a water inlet of the water pump; one end of the water outlet pipe is connected with a water outlet of the water pump, while the other end is connected with the spray head pipe; and one end of the return pipe is connected with the spray head pipe, while the other end is connected with the water tank. The horizontal vacuuming device is characterized in that the side part of the water tank is provided with a vacuum tank, the vacuum connecting pipe is connected with the vacuum tank, the side part of the spray head pipe is connected with one end of a connecting pipe, the other end of the connecting pipe is connected with the vacuum tank, an air suction opening of the connecting pipe is communicated with a pipe cavity of the spray head pipe, and the return pipe is horizontally connected with the spray head pipe and the water tank respectively. The horizontal vacuuming device has the advantages that the delivery lift can be reduced, the pipeline can be shortened, energy saving can be achieved, the structure is reasonable, the spray head pipe can be not to be attacked by pollutants, the adaptability to a mounting place is strong.

Owner:江苏天泽新材料有限公司

Turbocharging system

InactiveCN103452601AExact responseSimple designMachines/enginesEngine componentsIntercoolerElectronic control unit

The invention discloses a turbocharging system and belongs to the technical field of an automobile engine. The turbocharging system comprises a turbine, an air filter, an air compressor, an intercooler, a generator and an electric motor, wherein the turbine is connected with an exhaust manifold; the generator is connected with the turbine; an outlet of the air filter is connected with an inlet of the air compressor; an outlet of the air compressor is connected with an inlet of the intercooler; an outlet of the intercooler is connected to a throttle valve of the engine; and moreover, the air compressor is also connected with the electric motor. According to the invention, the turbocharging system does not need to depend on air displacement; the air compressor is directly driven by the electric motor; the electric motor is controlled by an ECU (Electronic Control Unit) and is accurate and rapid to respond; surging and blockage of the air compressor do not need to be considered and blade design of the turbine is very simple; the air filter and the air compressor are arranged at the air inlet side nearby, so that an air inlet pipeline is greatly shortened; and a waste gate and a pressure protection valve are not required, the turbocharging system has a simple structure and is easy to match and the development period of the engine is greatly shortened.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

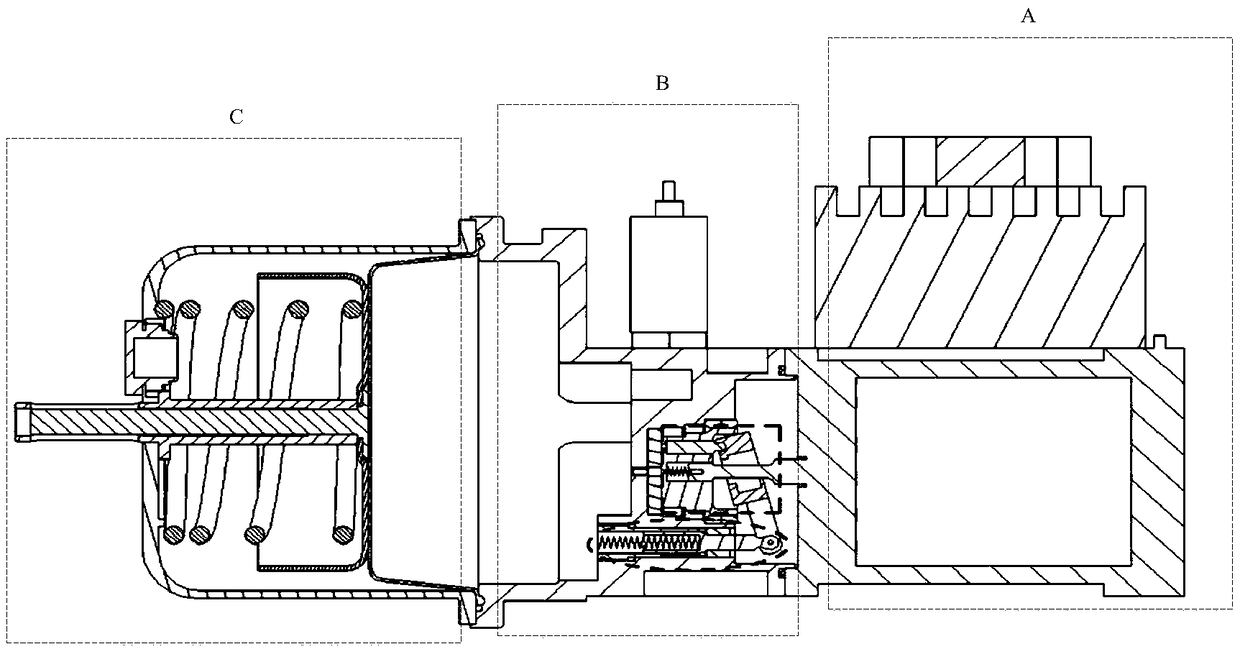

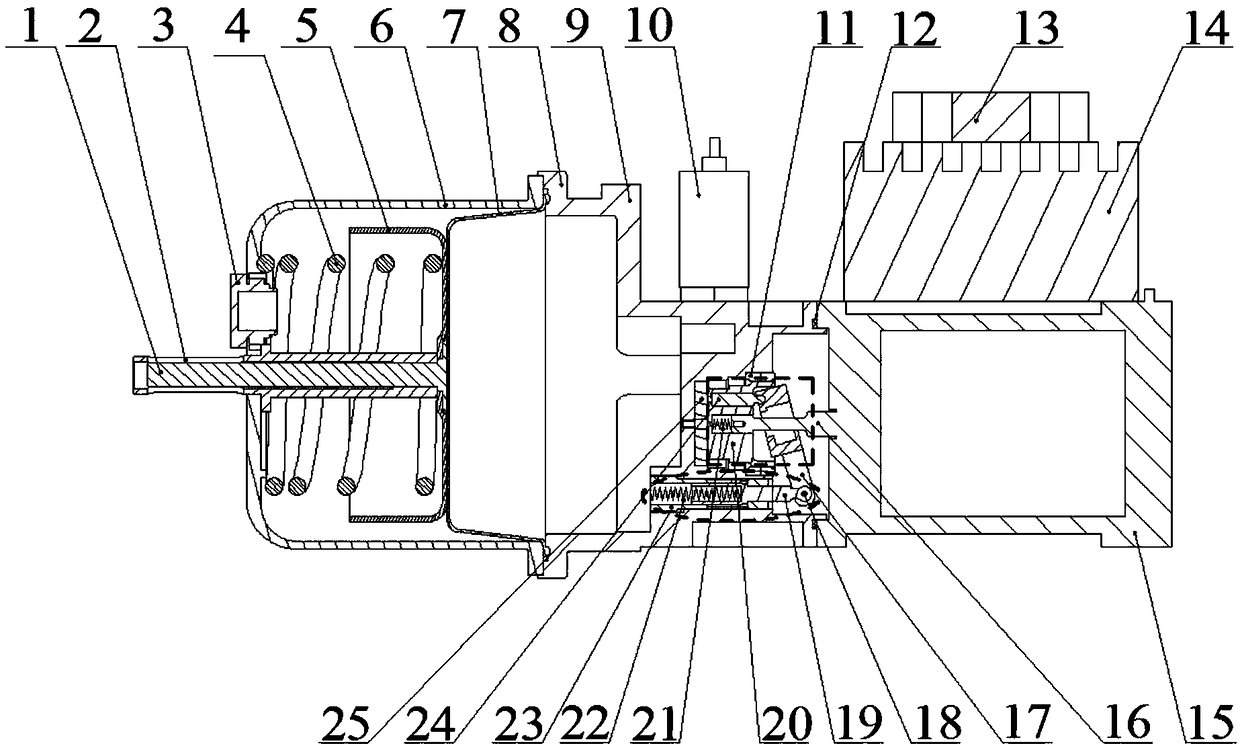

High-integration hydraulic power device

PendingCN109340219AShorten the axial lengthReduce jumpingFluid-pressure actuator componentsEngineeringMotor system

The invention discloses a high-integration hydraulic power device composed of three parts, namely, a motor system, a pump integrated block and an oil tank. The motor system comprises a motor, a driverand a cooling fan. A constant-pressure variable-displacement plunger pump is embedded in the pump integrated block. Accessories such as a sensor are installed on a shell of the constant-pressure variable-displacement plunger pump. The oil tank is composed of a push rod, a spring, a piston and a membrane. The motor and the plunger pump share one main shaft. A motor main shaft directly drags and rotates a plunger pump rotor to complete the oil suction and oil discharge process of the plunger pump, flow of oil is regulated through a piston drawing type variable-displacement mechanism, and therefore the function of constant pressure and variable displacement can be achieved. The high-integration hydraulic power device is used as a power conversion device of an airplane and has the beneficialeffects of being simple in structure, small in weight, easy to control, high in system efficiency and convenient to maintain.

Owner:JIANGSU JINLING INST OF INTELLIGENT MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com