Novel hydraulic motor transmission control valve group

A technology of hydraulic motor and transmission control, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve problems such as complex structure, and achieve the effect of reducing pipelines, shortening pipelines, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

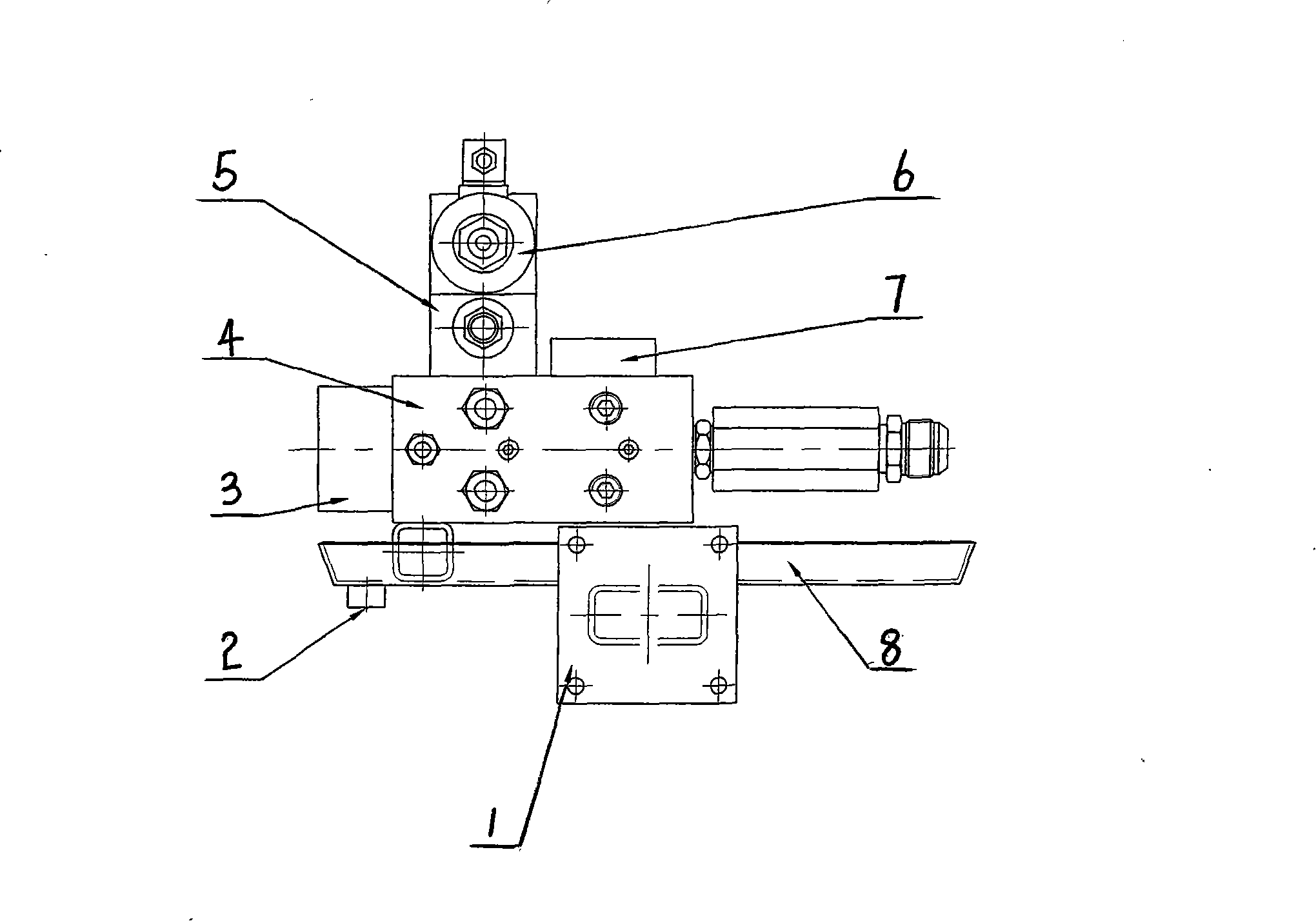

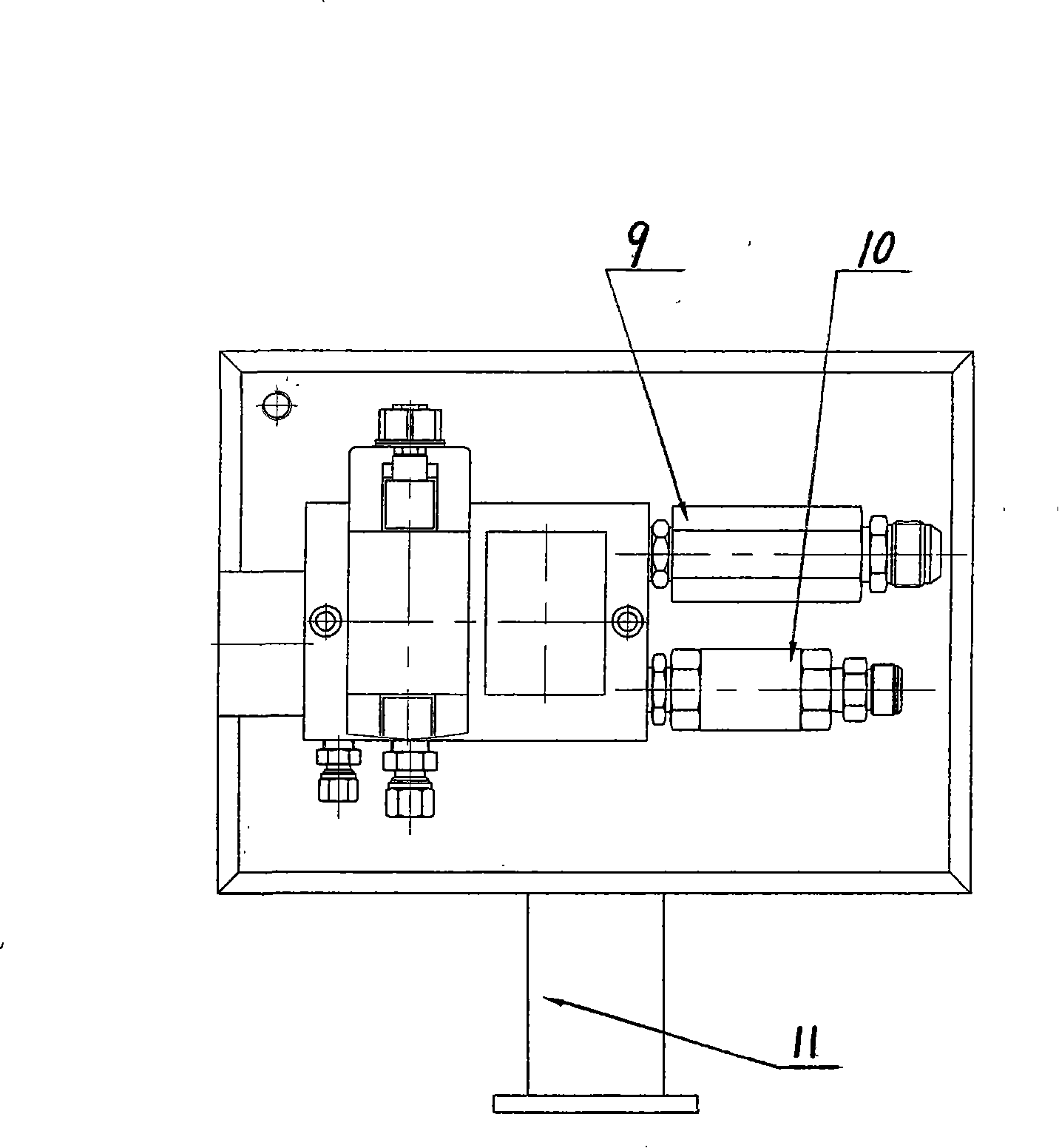

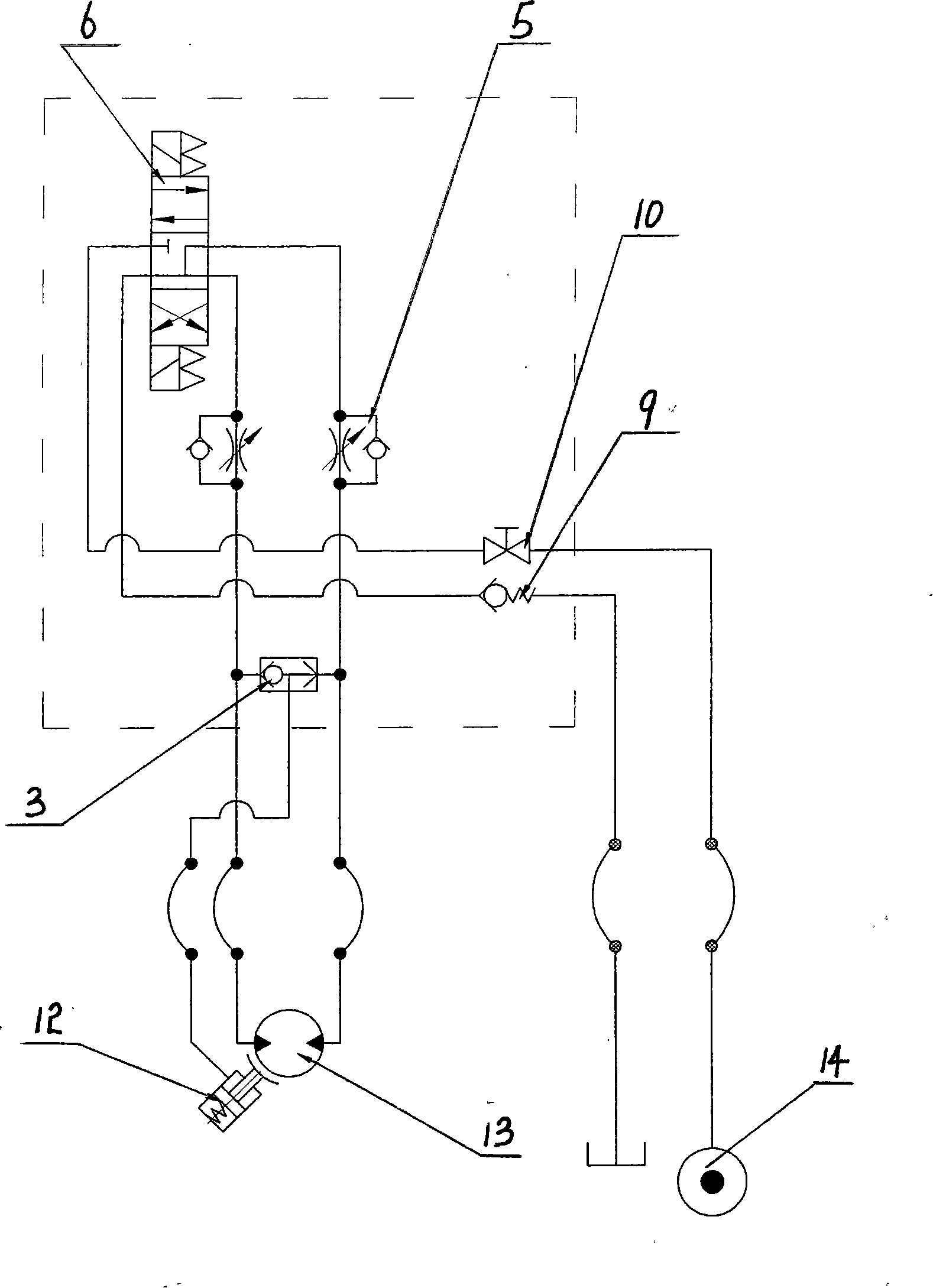

[0009] from figure 1 The structure schematic diagram and figure 2 It can be seen from the top view that the present invention mainly includes electromagnetic reversing valve 6, one-way throttle valve 5, shuttle valve 3, stack valve 7, one-way valve 9, ball valve 10, connecting valve block 4, oil receiving plate 8 and pipe Connectors etc. Brake (clutch) cylinder control valve adopts shuttle valve built-in two-way cartridge valve cover plate, electromagnetic reversing valve 6, one-way throttle valve 5, shuttle valve 3, stacking valve 7, one-way valve 9, ball valve 10 Installed on the connecting valve block 4, each control valve is connected with the connecting valve block 4 by pipe joints. The connecting valve block 4 is a metal cuboid, on which corresponding oil holes and threaded holes for installation and fastening are processed according to the specifications of various hydraulic valves and pipe joints installed, and several connecting channels are processed inside, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com