Multi-waveform electromagnetic excitation device of continuous casting crystallizer

A continuous casting mold and electromagnetic excitation technology, which is applied in the field of continuous casting mold electromagnetic vibration devices, can solve the problems of service life, maintenance cost and large floor space, and cannot meet the requirements of mold asymmetry and cannot produce non-sinusoidal Waveform and other problems, to achieve the effect of simple structure, energy saving and environmental protection maintenance, driving energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

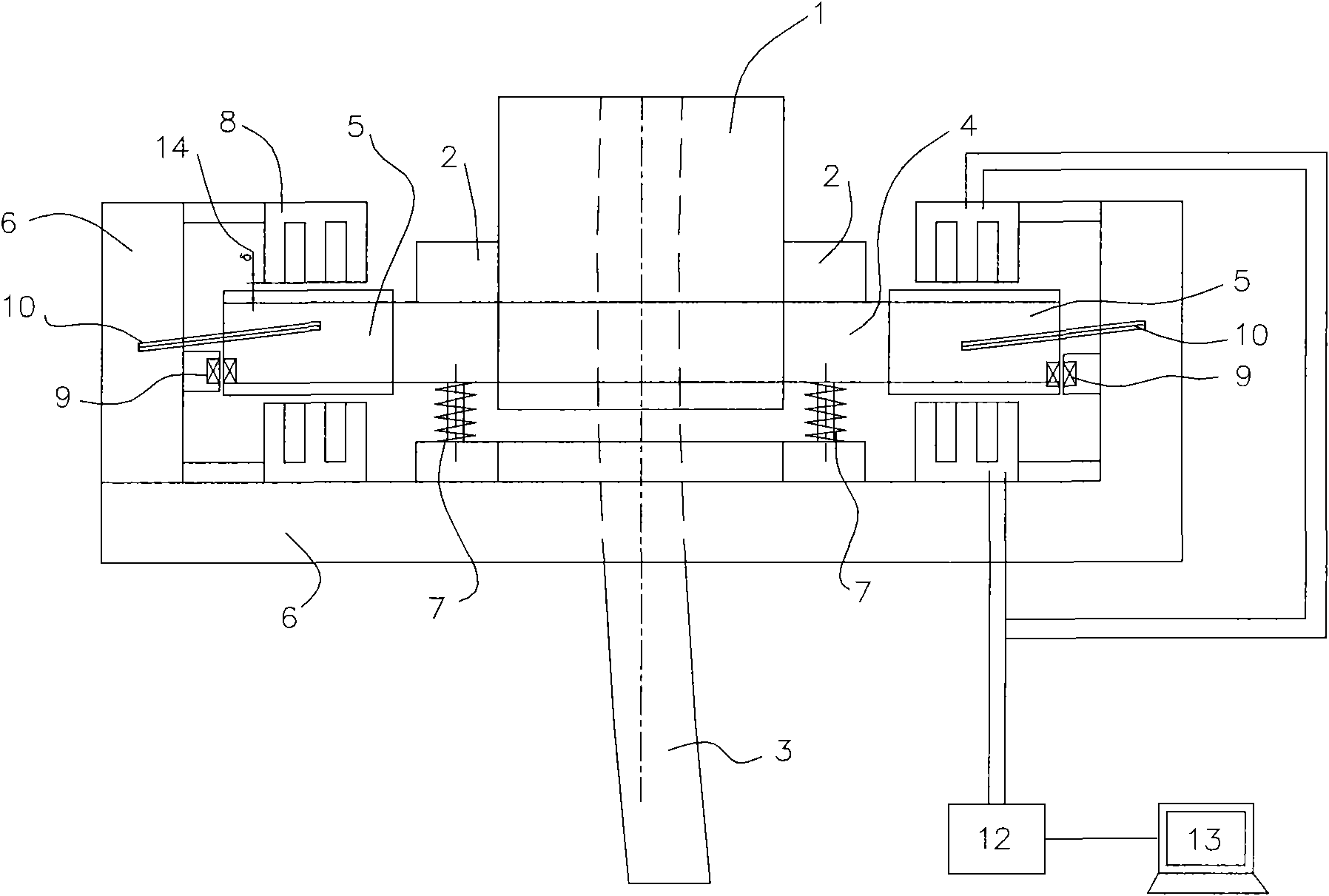

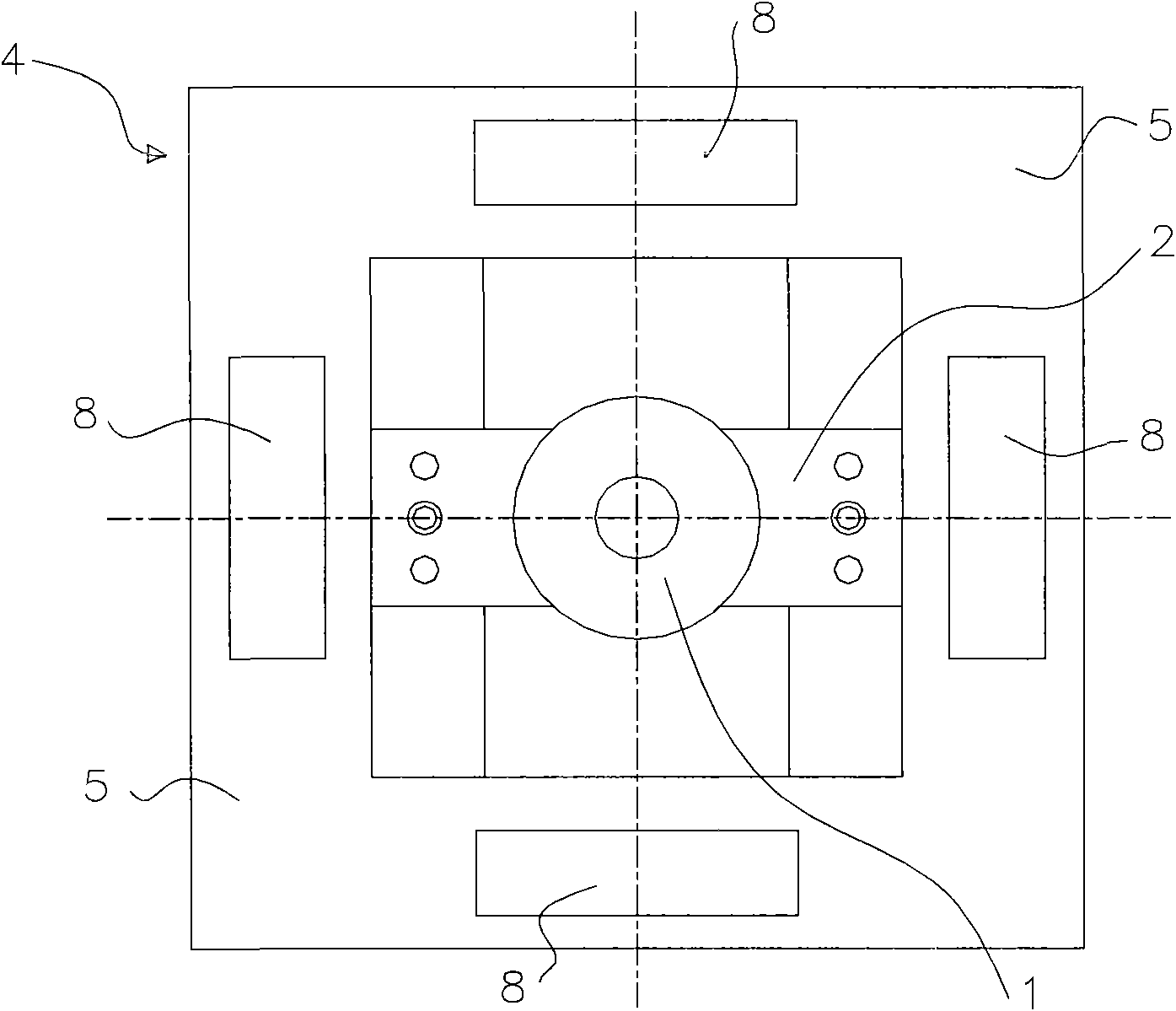

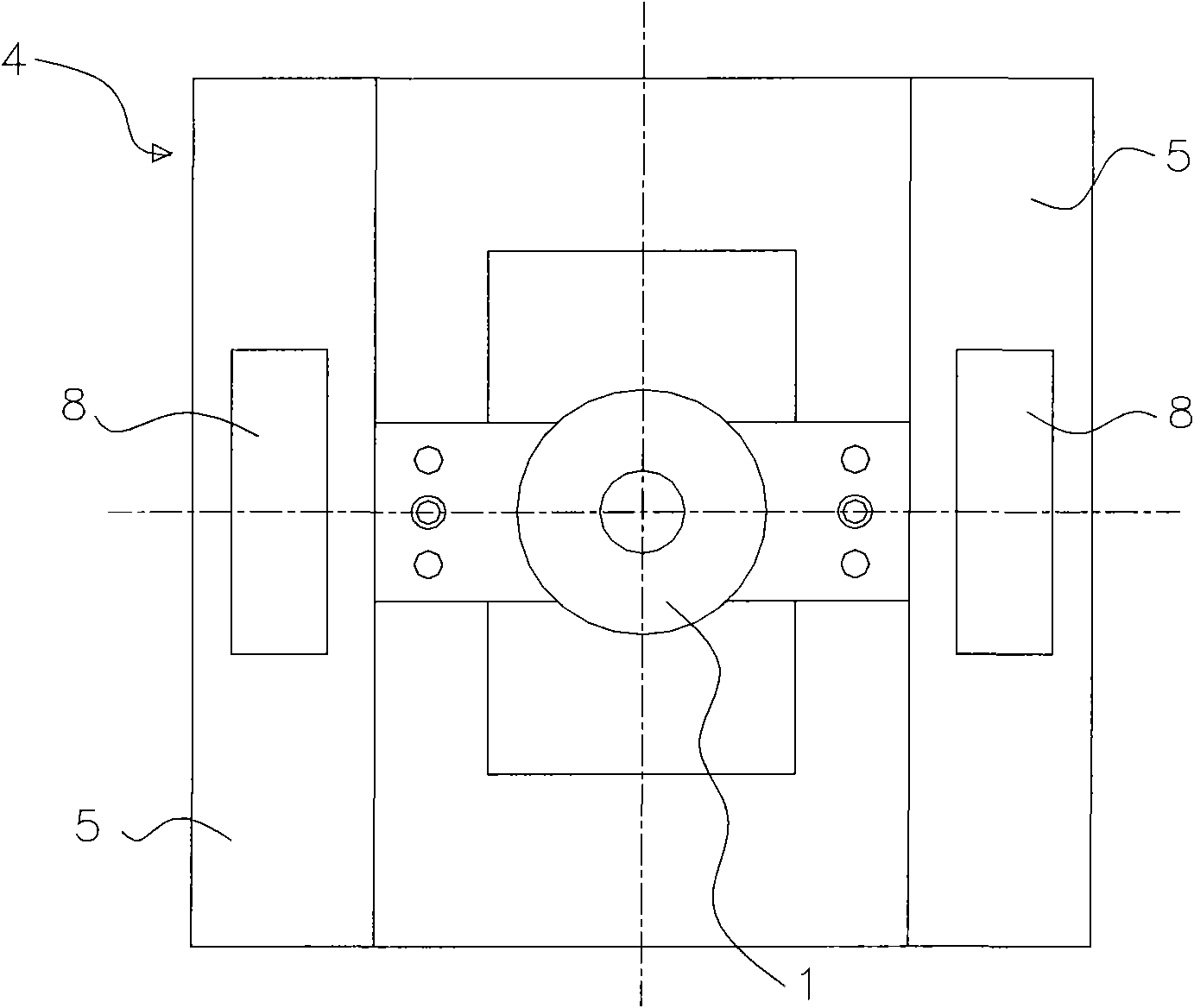

[0021] see figure 1 , a multi-waveform electromagnetic excitation device for a continuous casting mold, comprising a movable frame 4, a fixed frame 6, an elastic support assembly, an armature mechanism 5, a suspension electromagnet 8, a displacement sensor 9, a guide plate spring 10, a power amplifier 12 and a computer Control system 13; the two protruding ends 2 of the crystallizer 1 are installed and fixed on the movable frame 4, and the movable frame 4 is installed on the fixed frame 6 through elastic support components; An armature mechanism 5 is equipped with several pairs of suspension electromagnets 8 on the fixed frame 6. The pair of suspension electromagnets 8 is arranged up and down, and corresponds to an armature mechanism 5 up and down, that is, an armature mechanism 5 corresponds to one up and down. Suspension electromagnet 8; Sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com