Turbocharging system

A turbocharging system and turbine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as affecting engine air intake, complex testing, and disordered layout, and achieve shortened development cycles, accurate and fast response, and design. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

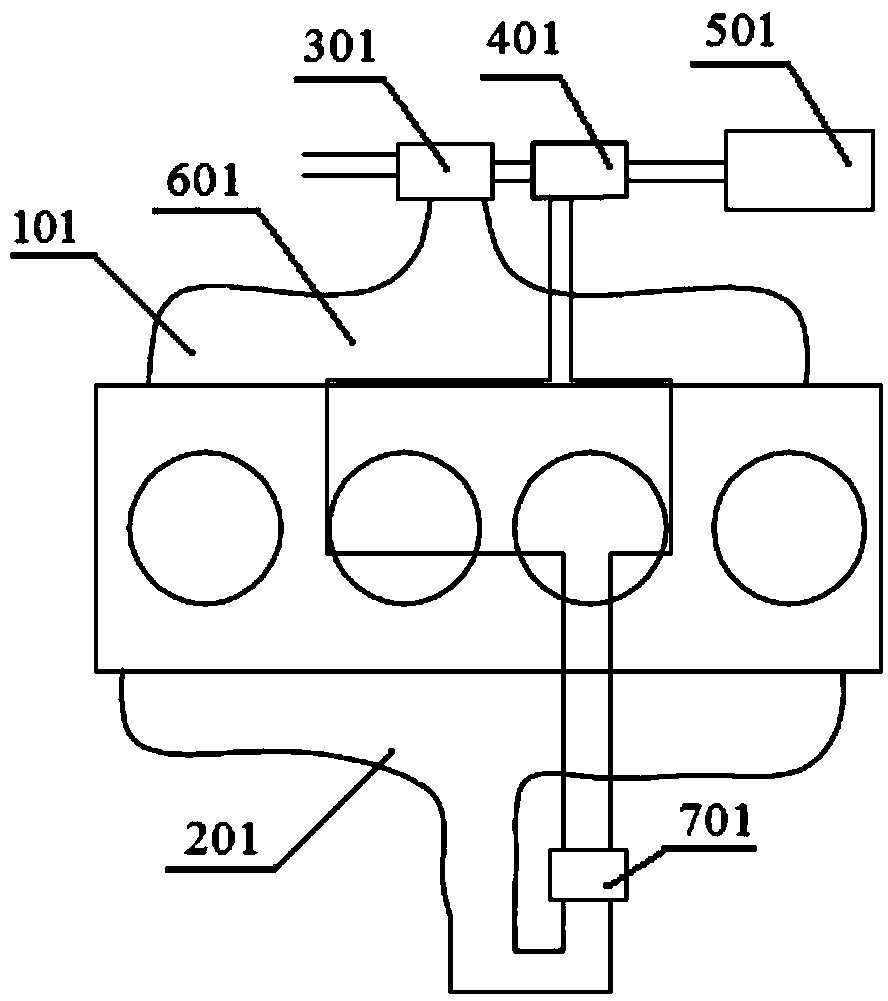

[0018] The traditional engine turbocharging system installs a turbine on the exhaust side, uses the energy of the exhaust gas to drive the compressor to inhale fresh air, saves energy and increases the intake power of the engine at the same time. Such as figure 1 Shown is a schematic structural diagram of a traditional engine turbocharging system, from which it can be seen that the system includes a turbine 301 connected to the exhaust manifold 101, a compressor 401 connected to the turbine 301, and an air filter 501 connected to the compressor 401 and Intercooler 601 ; wherein, the outlet of air filter 501 is connected to compressor 401 , and the other end of intercooler 601 is connected to throttle valve 701 . During operation, the intake air passes through the air filter 501 , the compressor 401 , the intercooler 601 in turn, and then reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com