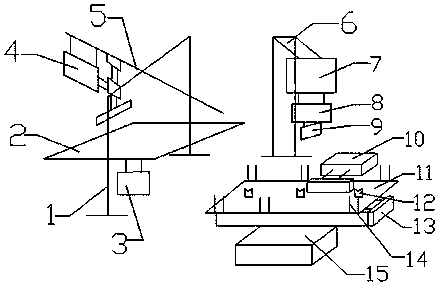

Automatic construction rebar bending mechanism

A technology of bending mechanism and building steel bar, which is applied in the field of building material processing equipment, can solve the problems of steel bar bending machine such as single function, low work efficiency, and affecting processing efficiency, so as to shorten the assembly line and processing time, improve work efficiency, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

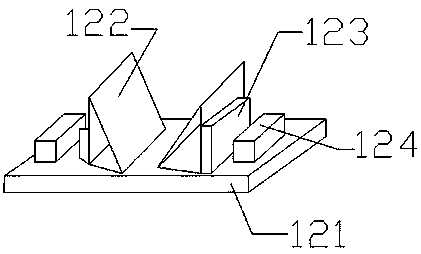

Examples

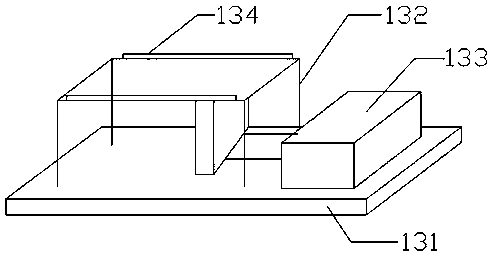

Embodiment 2

[0028] Embodiment 2: The feeding and pushing assembly 4 includes a feeding and pushing power element, a feeding chute and a feeding push block matched with the feeding slide rail 5; the fixed end of the feeding and pushing power element is fixedly connected with one end of the feeding slide rail 5, and the feeding and pushing power element The working end of the feeding chute is slidingly connected with the lower wall of the feeding slide rail 5 through the upper wall of the feeding chute, and the lower end of the feeding chute is fixedly connected with the feeding push block; further, the feeding pushing power element can be a standard cylinder pneumatic element; when the feeding lifting assembly 3 Work After the material bin 2 is raised to a certain height, the feeding and pushing power element works, that is, the telescopic rod in the feeding and pushing power element is extended, and the steel bar in the material bin 2 is pushed to the material plate 11 by using the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com