Horizontal evacuating device

A vacuum device, horizontal technology, applied in the direction of non-volume pumps, machines/engines, mechanical equipment, etc., can solve the problems of large head of the circulation mechanism, shutdown for maintenance, accumulation of dirt in the nozzle tube 3, etc., to achieve location selection Reasonable, adaptable, and the effect of reducing head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

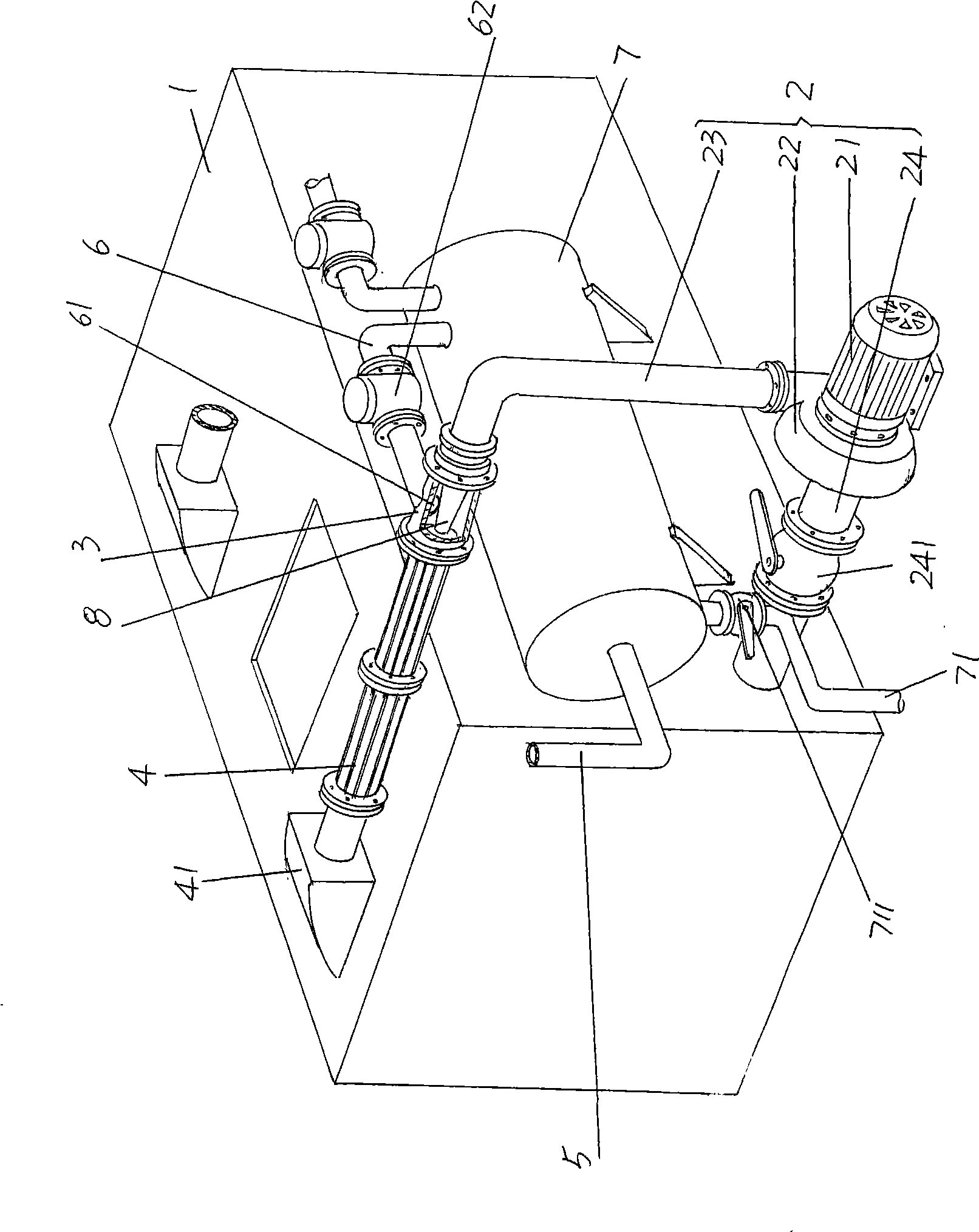

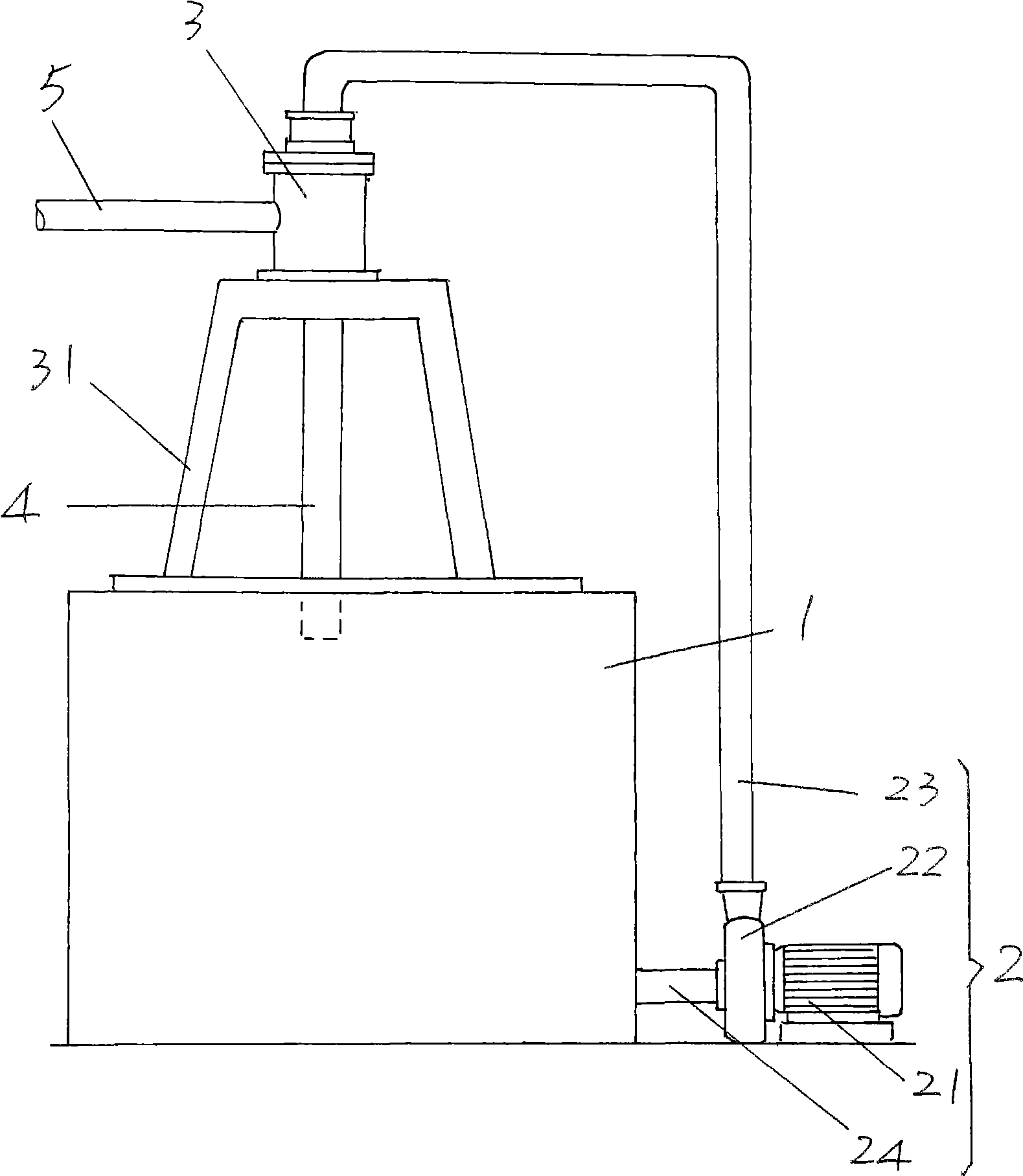

[0014] please see figure 1 , a rectangular water tank 1 is provided, more specifically a cuboid water tank 1 is provided, and the tank body 1 is made of a non-metallic material with good acid resistance. One end of the water inlet pipe 24 of the water circulation mechanism 2 connected in series between the water tank 1 and the nozzle pipe 3 is connected to the water tank 1, and the other end is connected to the water inlet of the water pump 22. The water pump 22 is matched with the motor 21, and one end of the water outlet pipe 23 It is connected with the water outlet of the water pump 22, and the other end is connected with the nozzle pipe 3. In the nozzle pipe 3, a nozzle 8 is provided. The water inlet of the nozzle 8 is connected to the water outlet pipe 23 through a flange and communicated with each other. One end of the connecting pipe 6 on the upper side of the nozzle pipe 3, the other end of the connecting pipe 6 is connected with the vacuum tank 7, and a valve 62 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com