Liquid C5 vaporisation apparatus

A gasification device, liquid technology, applied in the field of liquid carbon five gasification device, can solve problems such as troublesome operation, increased unsafe factors, harsh use conditions, etc., achieve the effects of simple overall structure, enhanced gasification effect, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

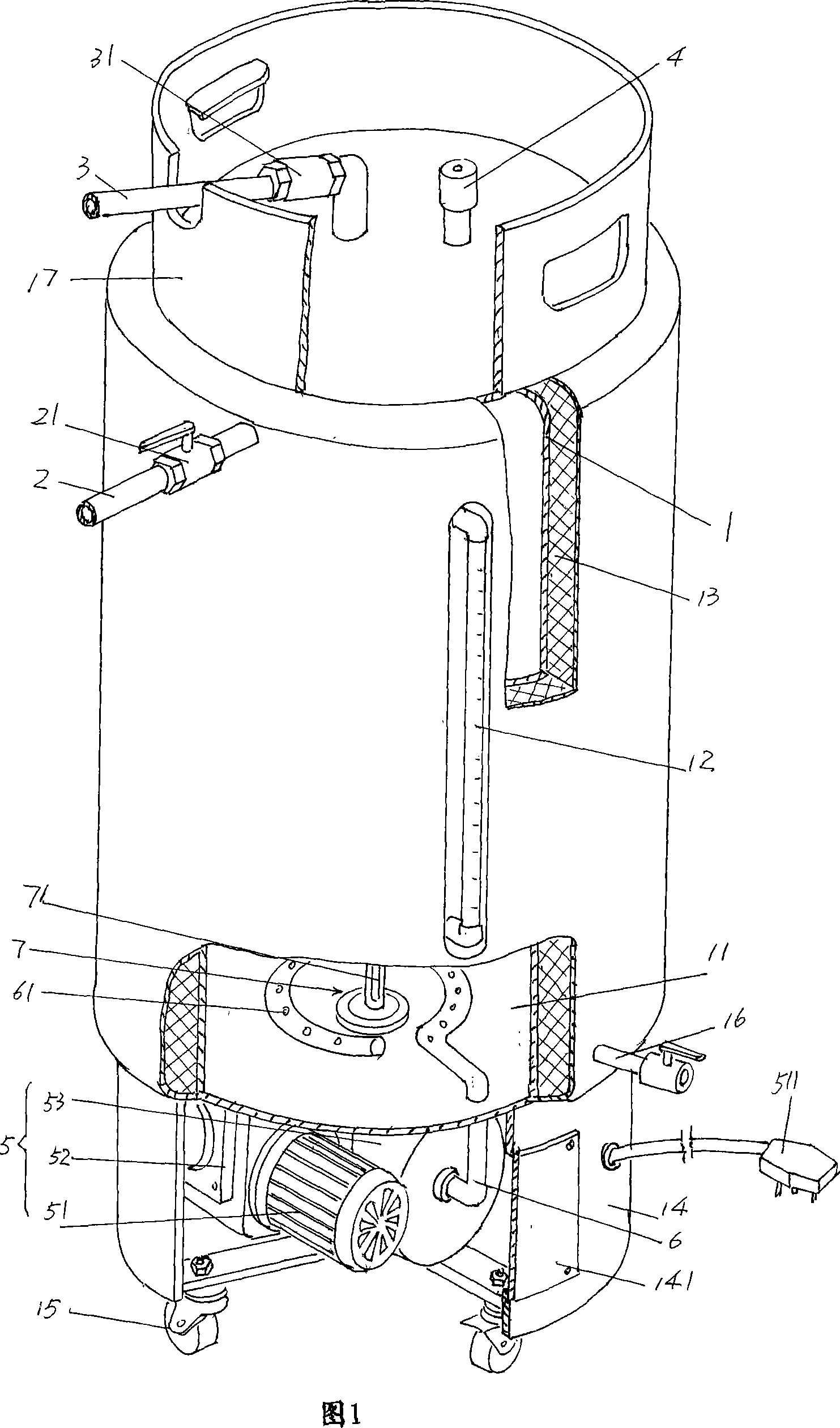

[0028] Please see Fig. 1, this figure is as the preferred embodiment structural diagram that the present invention recommends, and it has provided the tank body 1 that can bear certain pressure, and this tank body 1 just belongs to the steel cylinder of pressure vessel category seen in daily life, it is fully enclosed. The above-mentioned preferred location of the feed port 2 communicating with the tank cavity 11 is the upper side of the tank body 1 , and a feed valve 21 is provided on the feed port 2 . When the tank cavity 11 of the tank body 1 is to be injected as the material liquid for gasification, that is, the liquid carbon five raw material, it is only necessary to open the feed valve 21, and then close it after filling. When pouring liquid carbon five raw materials into the tank chamber 11, the vent valve 4 should be opened, and the gas in the tank chamber 11 will be released by the vent valve 4, so as to ensure that the liquid five carbon raw materials enter the tank ...

Embodiment 2

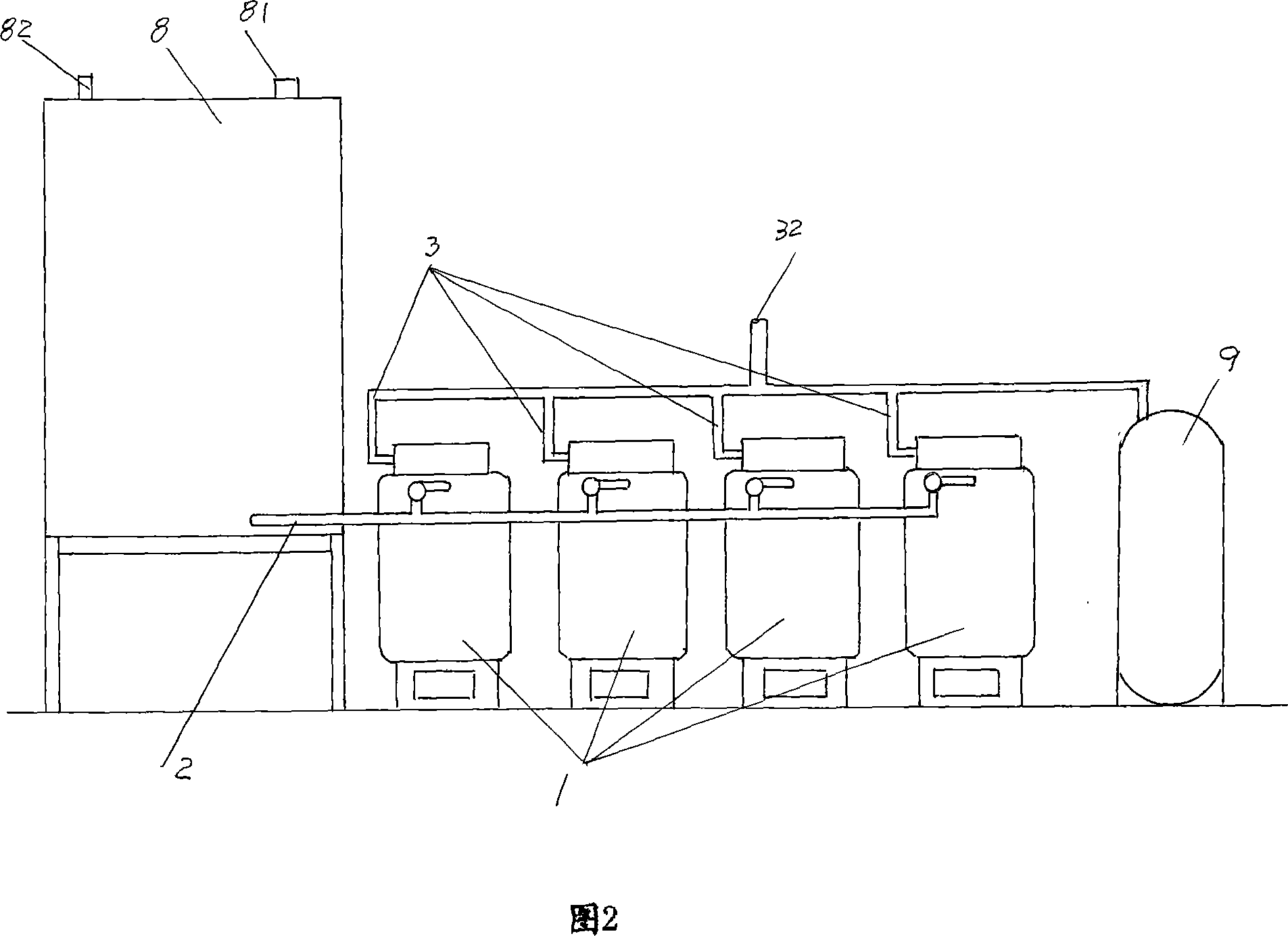

[0035]Please refer to Fig. 2, several liquid carbon five gasification devices of the present invention shown in embodiment 1 are assembled together to form a gasification device group, although the number is 4 in the figure, it is not limited by the specific number. The material receiving port 81 of the storage tank 8 receives the liquid C5 raw material. When receiving the material, the automatic air release valve 82 arranged on the storage tank 8 is opened. The feed ports 2 of each gasification device are merged into one, and communicate with the storage tank 8; in the same example, the air-introduction ports 3 of each gasification device are also merged into one, and connected to the main gas delivery pipe 32 and the gas collection Bucket 9 coupling. The main gas delivery pipe 32 is connected with the above-mentioned large gas consumption devices such as gas stoves, blast furnaces, gas boilers, etc., and the gas collection barrel 9 is used to store gasified gas. From this w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com