Gas inlet structure for pressure swing adsorption drying machine and nitrogen oxygen generator

A technology of pressure swing adsorption and air intake structure, applied in the direction of oxygen/ozone/oxide/hydroxide, inorganic chemistry, nitrogen compounds, etc., can solve the problems of uncompact equipment structure, complicated production and control, and achieve The effect of simple installation, simple production and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

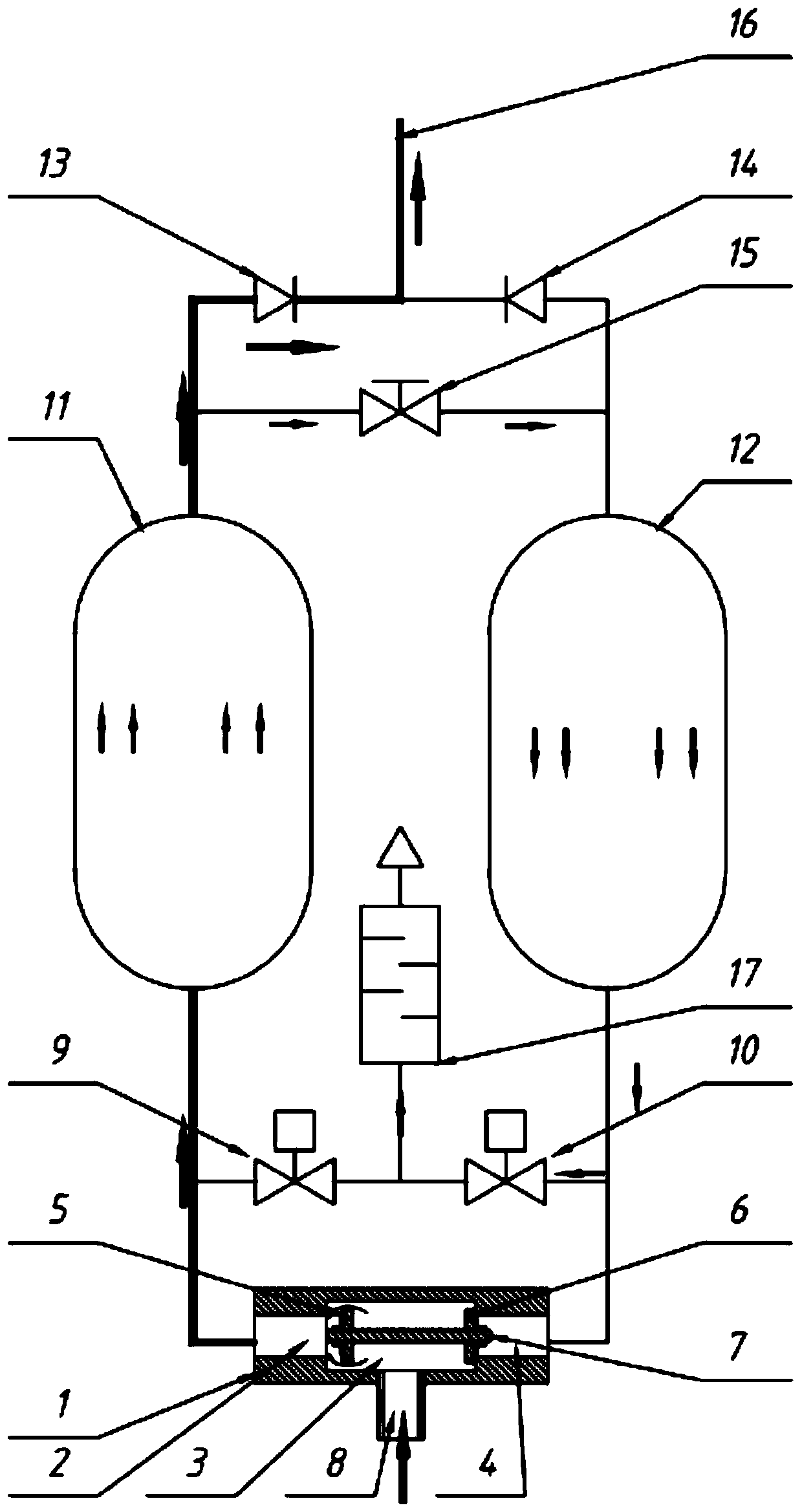

[0027] Embodiment 1: refer to figure 1 , the present invention provides a pressure swing adsorption dryer intake structure, or the structure of a nitrogen and oxygen generator, which includes a valve body 1, a first adsorption tank 11 and a second adsorption tank 12, the valve 1 penetrates through the A first cavity 2, a second cavity 3 and a third cavity 4 are provided in sequence, and the two ends of the second cavity 3 communicate with the first cavity 2 and the third cavity 4 respectively, and the second cavity The chamber 3 is connected to the gas inlet 8, and a valve core 7 is slidingly provided in the second cavity 3. The valve core 7 is preferably I-shaped, and the gas inlet 8 is connected to the middle part of the valve core 7. The two ends of the valve core 7 are respectively set A first valve plate 5 and a second valve plate 6 are used to open and close the vents at both ends of the second cavity 3, the first cavity 2 is connected to the lower part of the inner cav...

Embodiment 2

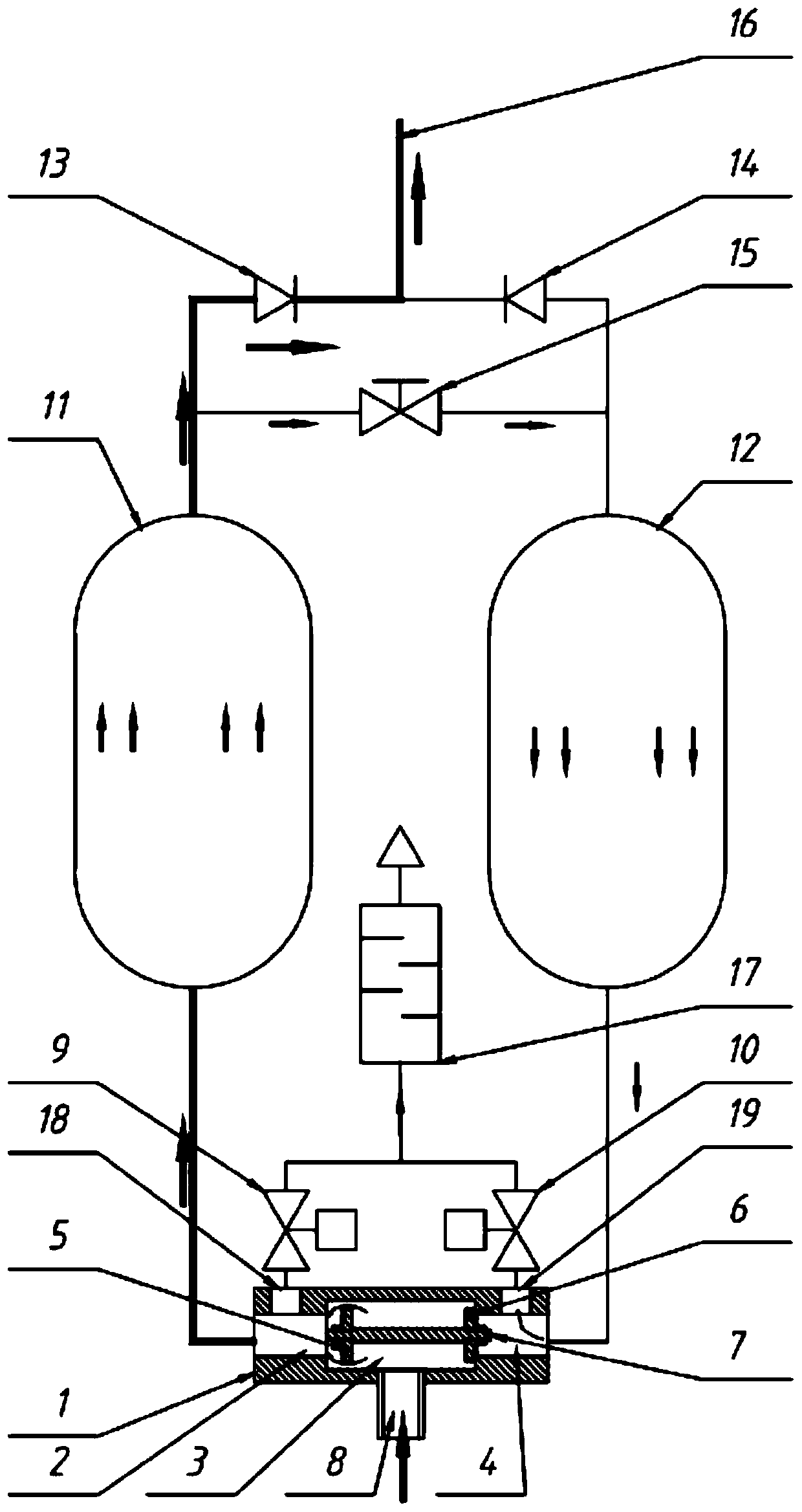

[0034] Embodiment 2: refer to figure 2 Compared with Embodiment 1, the difference is that: the first cavity 2 is also provided with a first outlet 18, the third cavity 4 is provided with a second outlet 19, and the first exhaust device 9 is connected to the first outlet. An outlet 18 to which the second exhaust device 10 is connected.

Embodiment 3

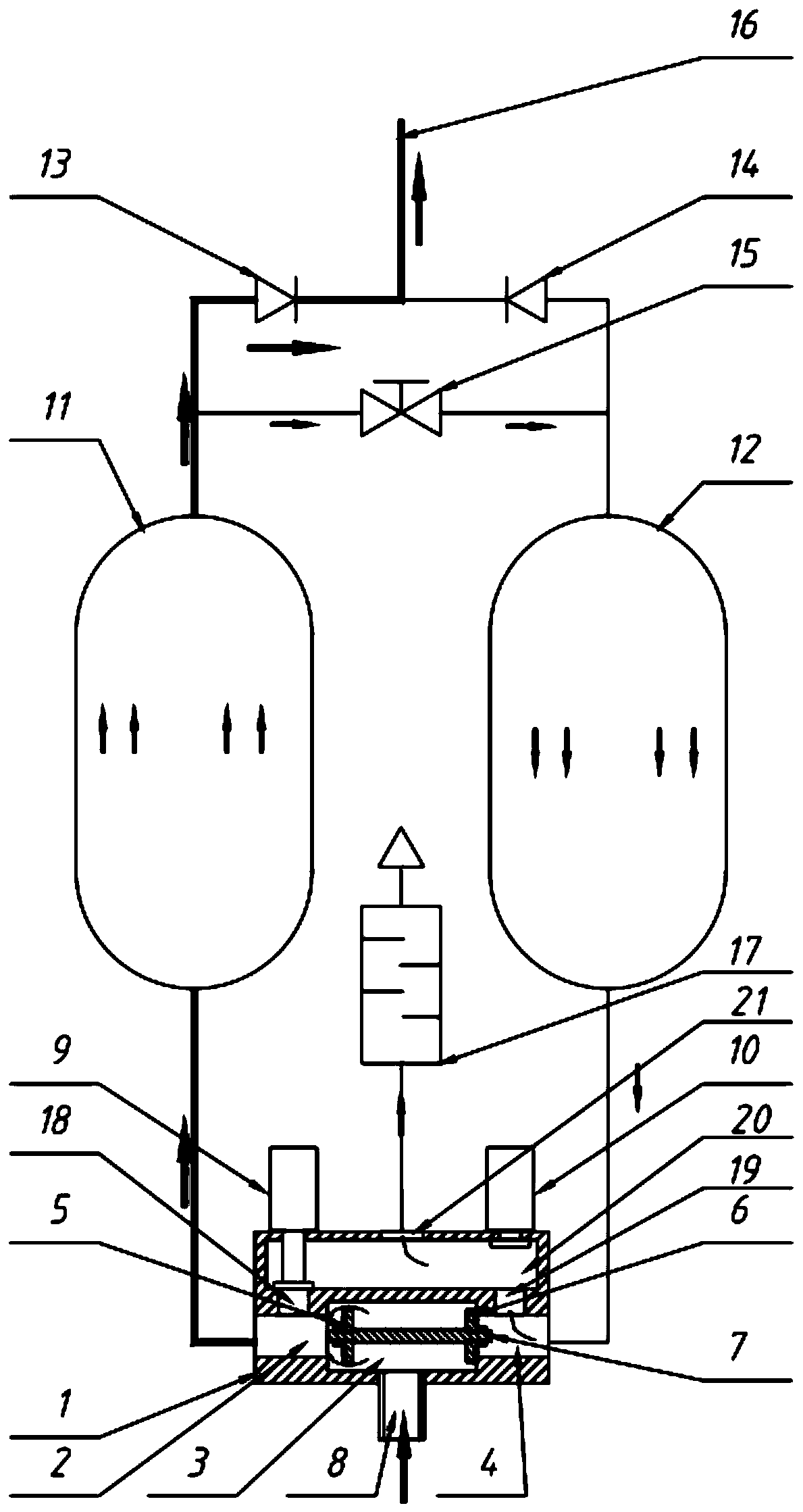

[0035] Embodiment 3: refer to image 3 , the present invention provides a pressure swing adsorption dryer intake structure, or the structure of a nitrogen and oxygen generator, which includes a valve body 1, a first adsorption tank 11 and a second adsorption tank 12, the valve 1 penetrates through the A first cavity 2, a second cavity 3 and a third cavity 4 are provided in sequence, and the two ends of the second cavity 3 communicate with the first cavity 2 and the third cavity 4 respectively, and the second cavity The chamber 3 is connected to the gas inlet 8, and a valve core 7 is slidingly provided in the second cavity 3. The valve core 7 is preferably I-shaped, and the gas inlet 8 is connected to the middle part of the valve core 7. The two ends of the valve core 7 are respectively set There are a first valve plate 5 and a second valve plate 6 for opening and closing the vents at both ends of the second cavity 3 . The valve body 1 is also provided with a fourth cavity 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com