High-integration hydraulic power device

A technology that integrates hydraulics and power devices. It is used in fluid pressure actuation devices, fluid pressure actuation system components, and mechanical equipment. It can solve problems such as unreasonable space layout, complicated pipelines, and low reliability, and achieve cooling effects. Good, low coefficient of friction, improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

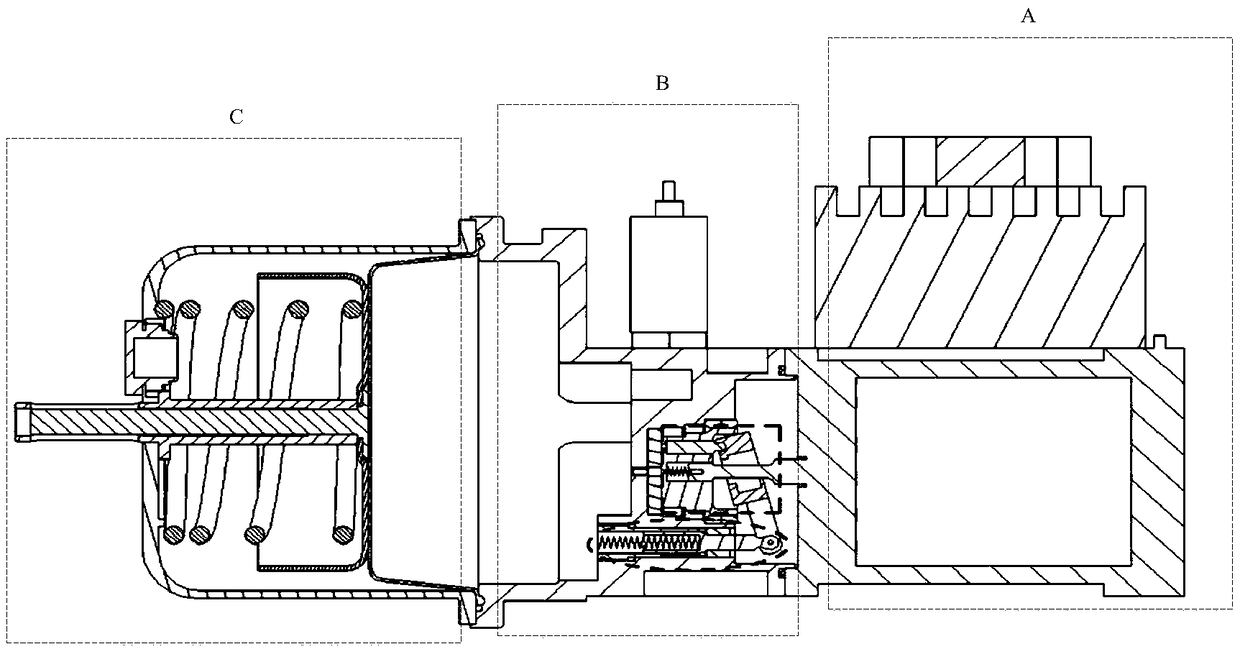

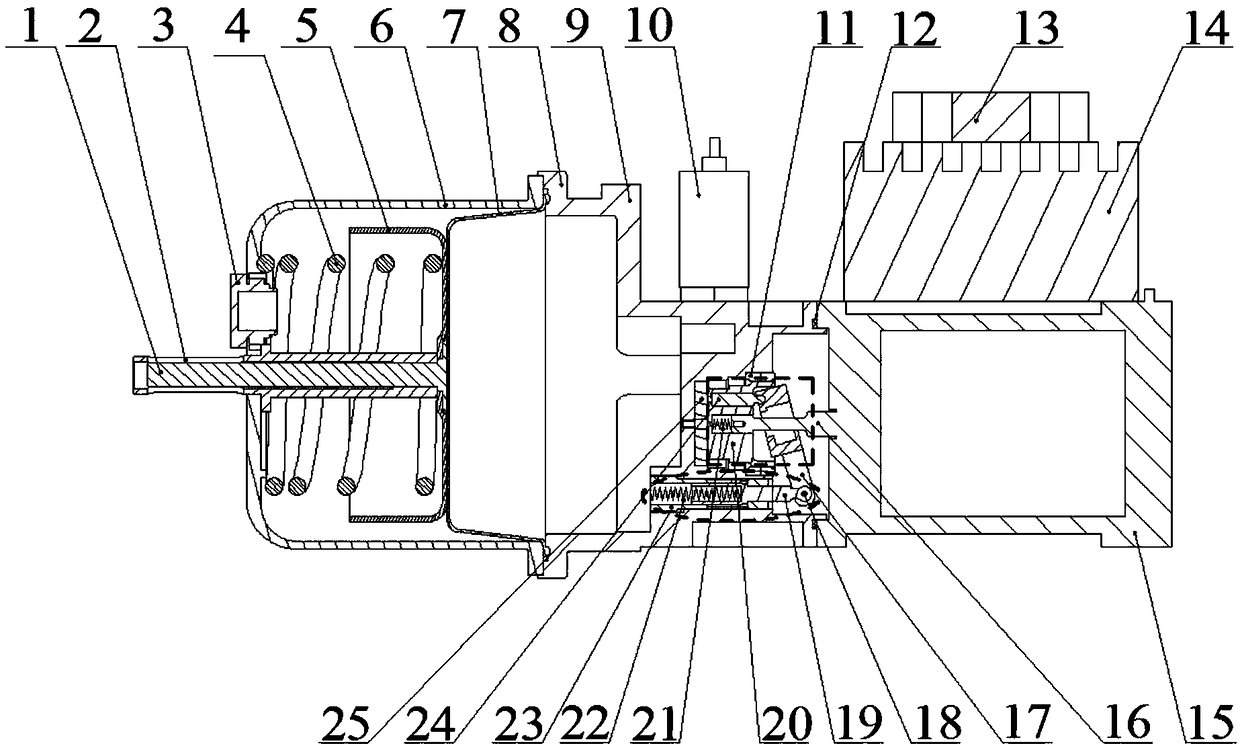

[0032] combine figure 1 , a highly integrated hydraulic power pack device, which is composed of motor system A, pump manifold B, fuel tank C, and three major parts. The pump manifold B is in the middle position, and the left and right sides are respectively connected to the fuel tank C and the motor system A by screws. .

[0033] combine figure 2 , the motor system A includes motor 15, driver 14, cooling fan 13 three parts, motor 15 adopts the mode of horizontal installation, and utilizes screw to fix driver 14 and cooling fan 13 on the top of the motor in sequence; Oil motor, able to bear the pressure of oil. The driver 14 is installed above the motor to control the start and stop of the motor, and the top of the driver 14 is designed as a heat dissipation rib structure. Cooling fans 13 are installed above the driver for cooling.

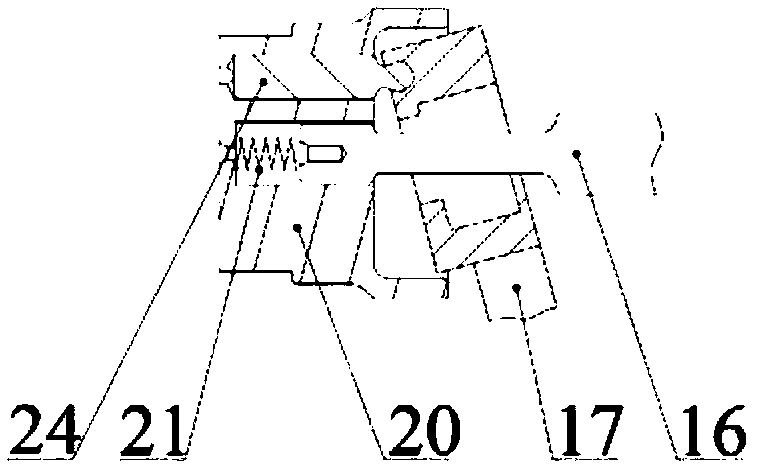

[0034] The pump manifold B is embedded with a constant pressure variable plunger pump, such as image 3 As shown, the plunger pump includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com