Reaction torque test method and tester

A technology of reaction force and testing method, which is applied in the direction of instruments, measuring devices, torque measurement, etc., can solve the problems of complex principle and structure, high failure rate of instruments, high maintenance requirements, etc., and achieve simple structure, complex structure and high technical difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

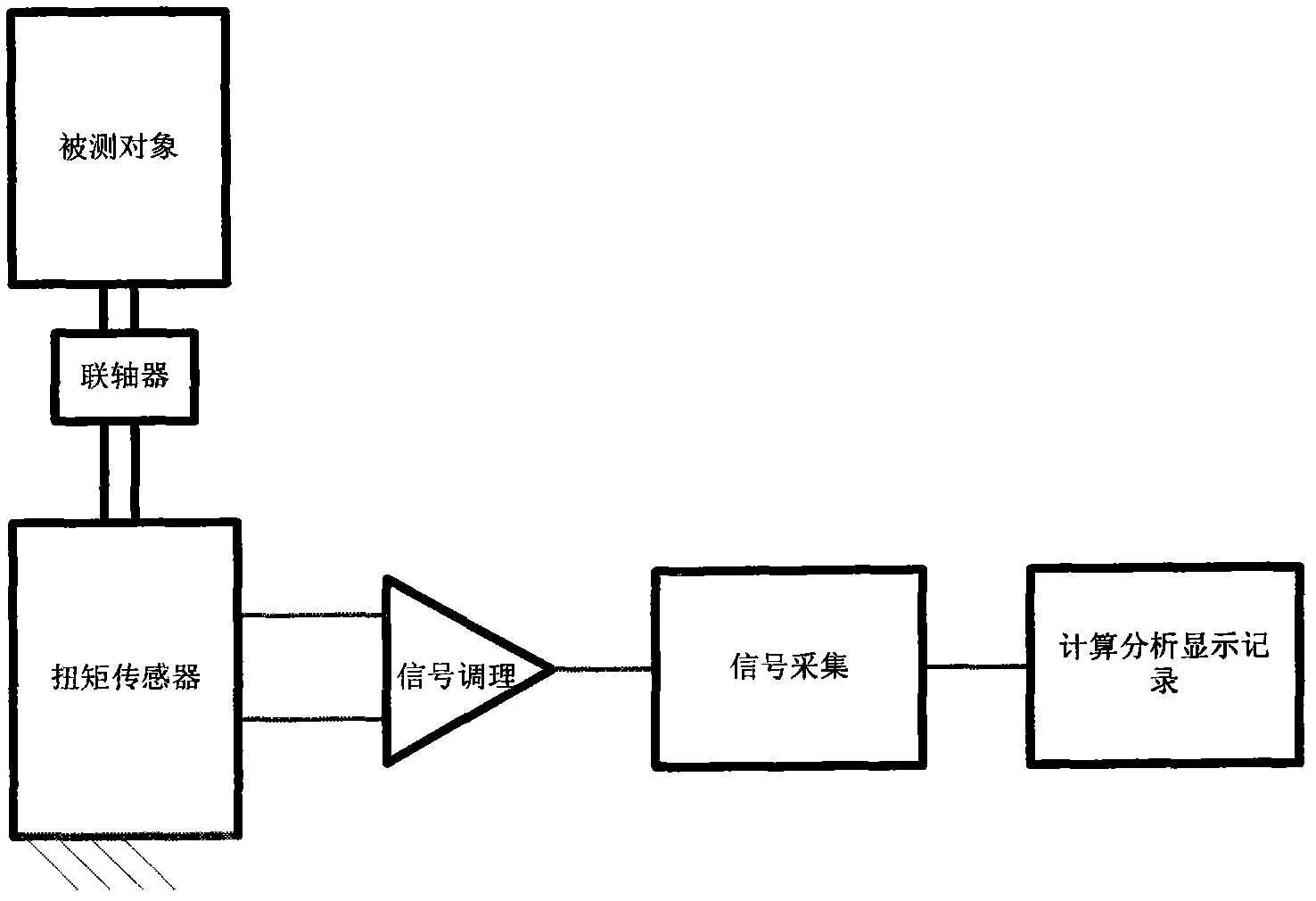

[0022] The reaction torque test method is to fix the stator shaft of the measured object through the coupling on the static torque sensor to obtain the electrical signal corresponding to the accurate small torque value of the measured object, and the electrical signal output by the sensor is processed by signal conditioning and data acquisition. Accurately obtain torque data; and use computer to process relevant data to obtain starting torque, load torque, friction torque and calculate inertia time and synchronization time.

[0023] The reaction torque tester for realizing the method has a static torque sensor, the coupling is fixed on the static torque sensor to obtain the accurate tiny torque value of the measured object, and the static torque sensor is connected with the signal conditioning and data acquisition system in turn Connect and access computer processing systems.

[0024] Through the analysis and research on the principle of motor parameter measurement, as long as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com