Efficient grinding mechanism for vertical roller mill

A vertical roller mill, high-efficiency technology, applied in grain processing and other directions, can solve the problems of low grinding efficiency, long production cycle, complicated manufacturing, etc., and achieve the effects of improving grinding efficiency, short maintenance cycle, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

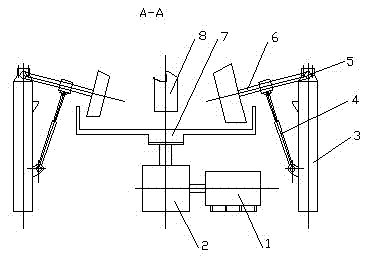

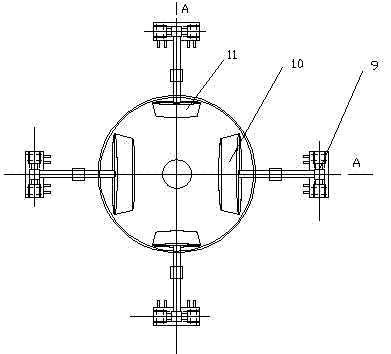

[0019] As shown in the accompanying drawings, the motor 1 drives the reducer 2 to run, and the grinding disc 7 connected to the output shaft of the reducer 2 makes a rotary motion at the same time. The material falls from the feeding pipe 8 to the center of the grinding disc 7, moves along the surface of the grinding disc 7 to the edge under the action of centrifugal force, and forms a material layer at the outer edge of the grinding disc surface. The rotary shaft 5 and the grinding roller shaft 6 installed in the bearing seat at the upper end of the column 3 together form a rocker arm, and the hydraulic (pneumatic) spring 4 controls the large grinding roller 10 and the small grinding roller through the rocker arm composed of the rotary shaft 5 and the grinding roller shaft 6. 11 Apply grinding pressure, the grinding disc 7 drives the grinding rollers to rotate along their respective grinding roller shafts 6 through the material layer, and the grinding disc and grinding rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com