Preparation method and application of ternary nano composite material based on MOF

A nanocomposite material and nanocrystal technology, applied in the fields of catalysis technology, nanomaterials, and metal organic framework materials, can solve problems such as distortion and resistance, and achieve the effects of easy operation, long preparation period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1. A kind of preparation method of MOF-based ternary nanocomposite material

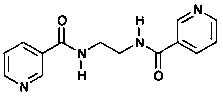

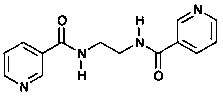

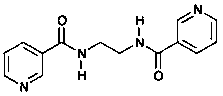

[0043] (1) Preparation of g-C 3 N 4 @MOF nanocrystals

[0044] 0.34 g AgClO 4 and 0.068 g graphitic carbon nitride g-C 3 N 4 dissolved in 1 mL of water to give g-C 3 N 4 @Ag(I) aqueous solution; 0.45 g ligand L was dissolved in 1 mL methanol to obtain a methanol solution of ligand L; g-C 3 N 4 The aqueous solution of @Ag(I) and the methanol solution of ligand L were shaken and blended, left standing for 2 h, centrifuged and washed with methanol for 3 times to obtain g-C 3 N 4 @MOF nanocrystals;

[0045] (2) Preparation of g-C 3 N 4 @MOF@Ag Nanocomposite

[0046] The prepared g-C 3 N 4 @ MOF nanocrystals, add 4 mL of KBr ethanol solution with a mass fraction of 5%, mix well, let stand at room temperature for 24 h, centrifuge and wash with ethanol three times, and dry at 70°C to obtain g-C 3 N 4 @MOF@Ag nanocomposites, that is, MOF-based ternary nanocomposites.

Embodiment 2

[0047] Example 2 A method for preparing a MOF-based ternary nanocomposite

[0048] (1) Preparation of g-C 3 N 4 @MOF nanocrystals

[0049] 0.45 g AgClO 4 and 0.090 g graphitic carbon nitride g-C 3 N 4 dissolved in 1.5 mL of water to give g-C 3 N 4 @Ag(I) aqueous solution; 0.45 g ligand L was dissolved in 2 mL methanol to obtain a methanol solution of ligand L; g-C 3 N 4 The aqueous solution of @Ag(I) and the methanol solution of ligand L were shaken and blended, left standing for 3 h, centrifuged and washed with methanol for 3 times to obtain g-C 3 N 4 @MOF nanocrystals;

[0050] (2) Preparation of g-C 3 N 4 @MOF@Ag Nanocomposite

[0051] The prepared g-C 3 N 4 @ MOF nanocrystals, add 6 mL of KBr ethanol solution with a mass fraction of 5%, mix well, let stand at room temperature for 24 h, centrifuge and wash with ethanol three times, and dry at 70°C to obtain g-C 3 N 4 @MOF@Ag nanocomposites, that is, MOF-based ternary nanocomposites.

Embodiment 3

[0053] 1. A method for preparing a ternary nanocomposite based on MOF, the steps are as follows:

[0054] (1) Preparation of g-C 3 N 4 @MOF nanocrystals

[0055] 0.40 g AgClO 4 and 0.075 g graphitic carbon nitride g-C 3 N 4 dissolved in 1.2 mL of water to give g-C 3 N 4 @Ag(I) aqueous solution; 0.45 g ligand L was dissolved in 1.5 mL methanol to obtain a methanol solution of ligand L; g-C 3 N 4 The aqueous solution of @Ag(I) and the methanol solution of ligand L were shaken and blended, left standing for 2.5 h, centrifuged and washed with methanol three times to obtain g-C 3 N 4 @MOF nanocrystals;

[0056] (2) Preparation of g-C 3 N 4 @MOF@Ag Nanocomposite

[0057] The prepared g-C 3 N 4 @ MOF nanocrystals, add 5 mL of KBr ethanol solution with a mass fraction of 5%, mix well, let stand at room temperature for 24 h, centrifuge and wash with ethanol three times, and dry at 70°C to obtain g-C 3 N 4 @MOF@Ag nanocomposites, that is, MOF-based ternary nanocomposite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com