Regular polygonal cylinder anode and method for preparing large-area metal microstructure through electrodeposition

A technology of regular polygonal cylinders and electrodeposition, applied in the direction of electrodes, can solve problems such as difficulty in ensuring uniform mask thickness, strict technical requirements for production equipment, and unsatisfactory metal microstructure effects, etc., to achieve easy automatic control and consistent The effect of high reliability and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

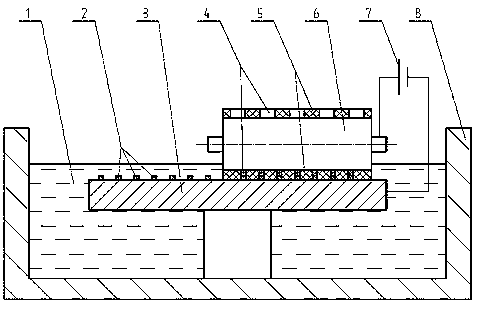

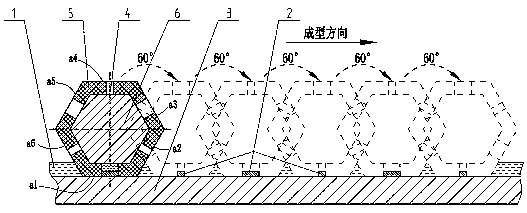

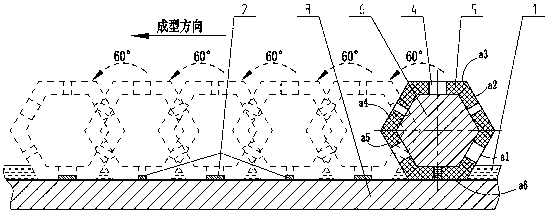

[0036] Embodiment 1: The regular polygonal cylindrical anode according to the present invention is composed of a regular hexagonal cylindrical anode 6 with a side length of 5 mm and a mask 5 with a hollow pattern array 4 . A mask 5 made of photoresist with a thickness of 0.3 mm is wrapped on the outer surface of a cylindrical anode 6 made of platinum, and the shapes and sizes of the hollow pattern arrays 4 on different mask planes are not exactly the same (see Figure 4 ). The positive multi-deformation cylindrical anode 6 driven by the numerical control device can rotate around its central axis and move horizontally.

[0037] The working method of preparing a large-area patterned metal structure by anodic electrodeposition of regular polygonal pillars is as follows.

[0038]Working method one: first place the conductive substrate 3 horizontally in the electrolyte tank 8, so that the a1 surface of the regular polygonal cylindrical anode 6 is parallel and closely attached to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com