Buckling-resistant lift cylinders

A technology for lifting and lowering cylinders and cylinders, used in lifting devices, fluid pressure actuating devices, plungers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

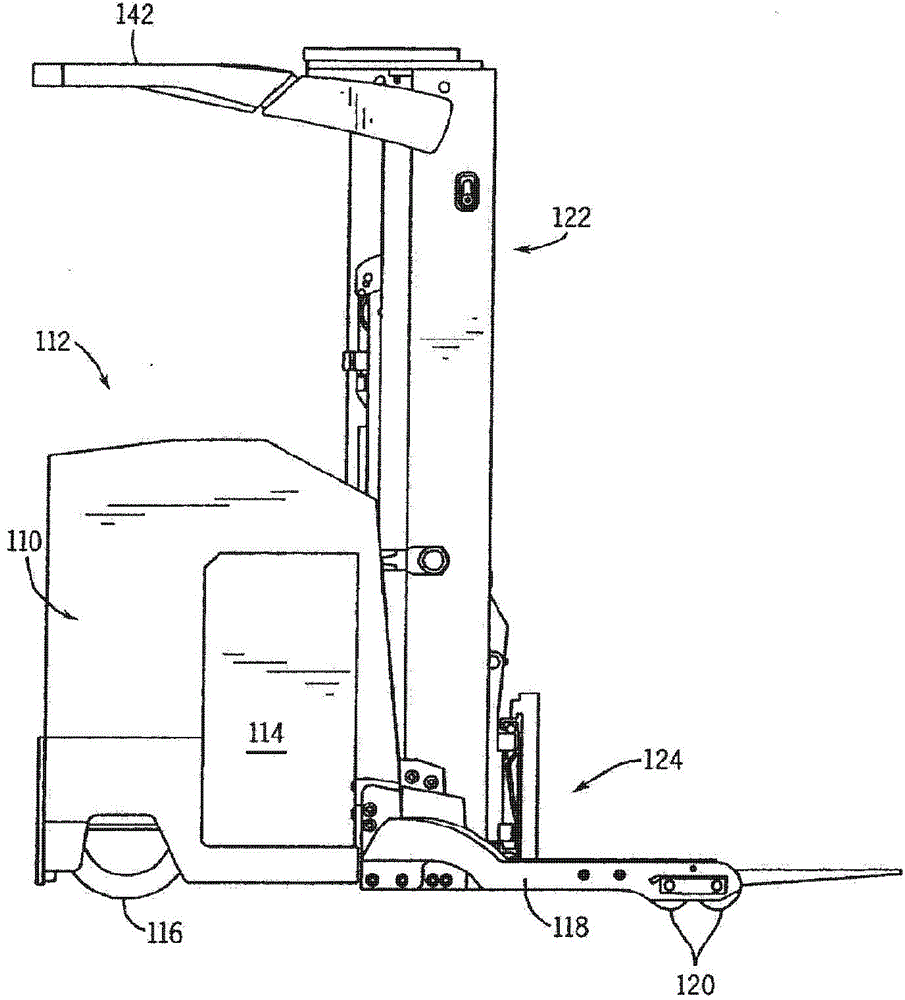

[0021] First refer to figure 1 , the exemplary lift truck includes a power unit 110 having a driver compartment 112 at the rear and a battery compartment 114 at the front. The battery powers a traction motor drive (not shown), which turns steerable drive wheels 116 to propel and steer the forklift. A pair of laterally spaced base legs 118 are indirectly connected to and extend forwardly from the power unit 110, and each base leg 118 includes wheels 120 for supporting a forklift. A mast assembly 122 is connected to the front end of the power unit 110 and extends vertically upward therefrom. The mast assembly 122 supports a fork carriage 124 that is used to lift or hoist objects to various heights.

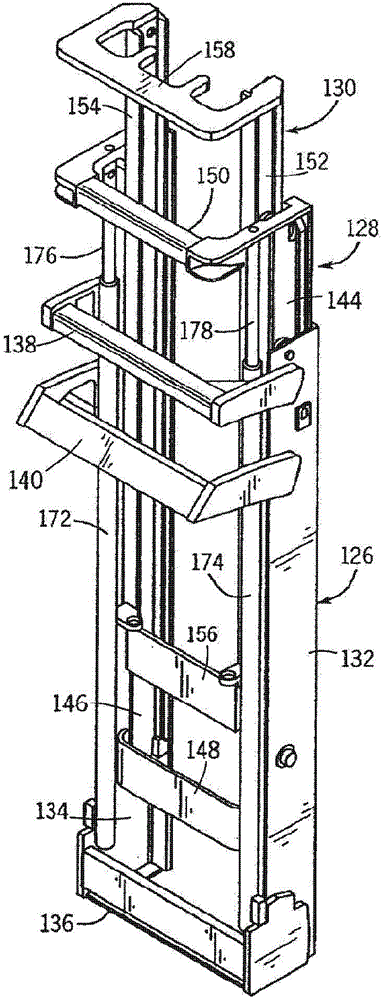

[0022] Now refer to figure 2 , the mast assembly 122 consists of three telescoping sections (although other numbers of sections could be used). These include a base portion 126 , an outer telescoping portion 128 , and an inner telescoping portion 130 . Rollers mounted to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com