Cation high-performance size

A high-performance, cationic technology, applied in the textile industry, can solve problems such as difficult handling and environmental pollution, and achieve the effects of easy handling, good fluidity, and stable slurry viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put 85kg of cornstarch, 10kg of trimethylamine hydrochloride, 3kg of calcium hydroxide, and 2kg of calcium persulfate into the reaction tank respectively, carry out the compound mixing reaction at 38°C for 1.5h, then terminate the reaction, unload the package, and put it into storage . When the customer is using it, add clear water to gelatinize and heat up to 95°C or add clear water in a high-pressure tank to heat up to 125°C and keep warm for 30-45 minutes to carry out etherification and oxidation compound reactions to obtain an emulsion for sizing fabrics.

Embodiment 2

[0026] Put 88kg of cornstarch, 8kg of trimethylamine hydrochloride, 2kg of calcium hydroxide, and 2kg of potassium hydrogen persulfate into the reaction tank respectively, carry out the compound mixing reaction at 38°C for 1.5h, and then terminate the reaction. library. When the customer is using it, add clear water to gelatinize and heat up to 95°C or add clear water in a high-pressure tank to heat up to 125°C and keep it warm for 30-45 minutes to carry out etherification and oxidation compound reactions to obtain a fabric sizing emulsion.

Embodiment 3

[0028] Put 92kg of cornstarch, 6kg of trimethylamine hydrochloride, 1kg of magnesium hydroxide, and 1kg of ammonium persulfate into the reaction tank respectively, carry out the compound mixing reaction at 38°C for 1.5h, then terminate the reaction, unload and pack, and store . When the customer is using it, add clear water to gelatinize and heat up to 95°C or add clear water in a high-pressure tank to heat up to 125°C and keep it warm for 30-45 minutes to carry out etherification and oxidation compound reactions to obtain a fabric sizing emulsion.

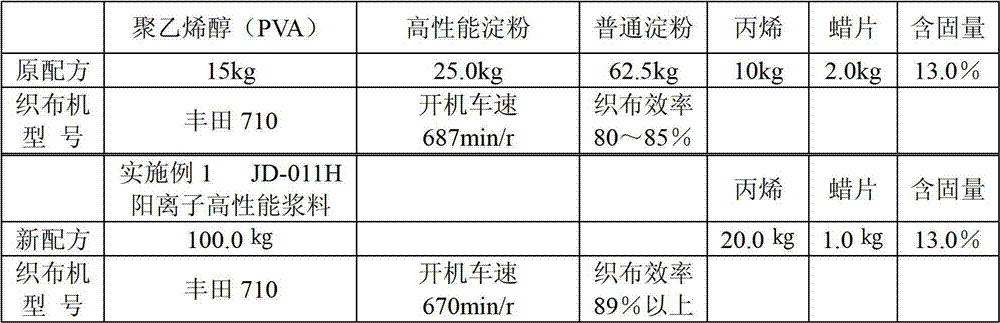

[0029] All or part of the emulsion size obtained in the above examples is used to replace the polyvinyl alcohol, high-performance starch and ordinary starch in the existing size formula, and the fabric is sized in actual production, and the existing formula is used for comparative experiments . The formulations and production conditions of each group are shown in the table below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com