Production technology for impellers with different lifts by utilizing existed impeller mold

A production process and impeller technology, applied in manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems of long production cycle, high cost, increased cost, etc., and achieve low production cost and cost, short production cycle, and cost. and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0019] A production process for producing impellers with different lifts by using existing impeller molds, the main process flow includes:

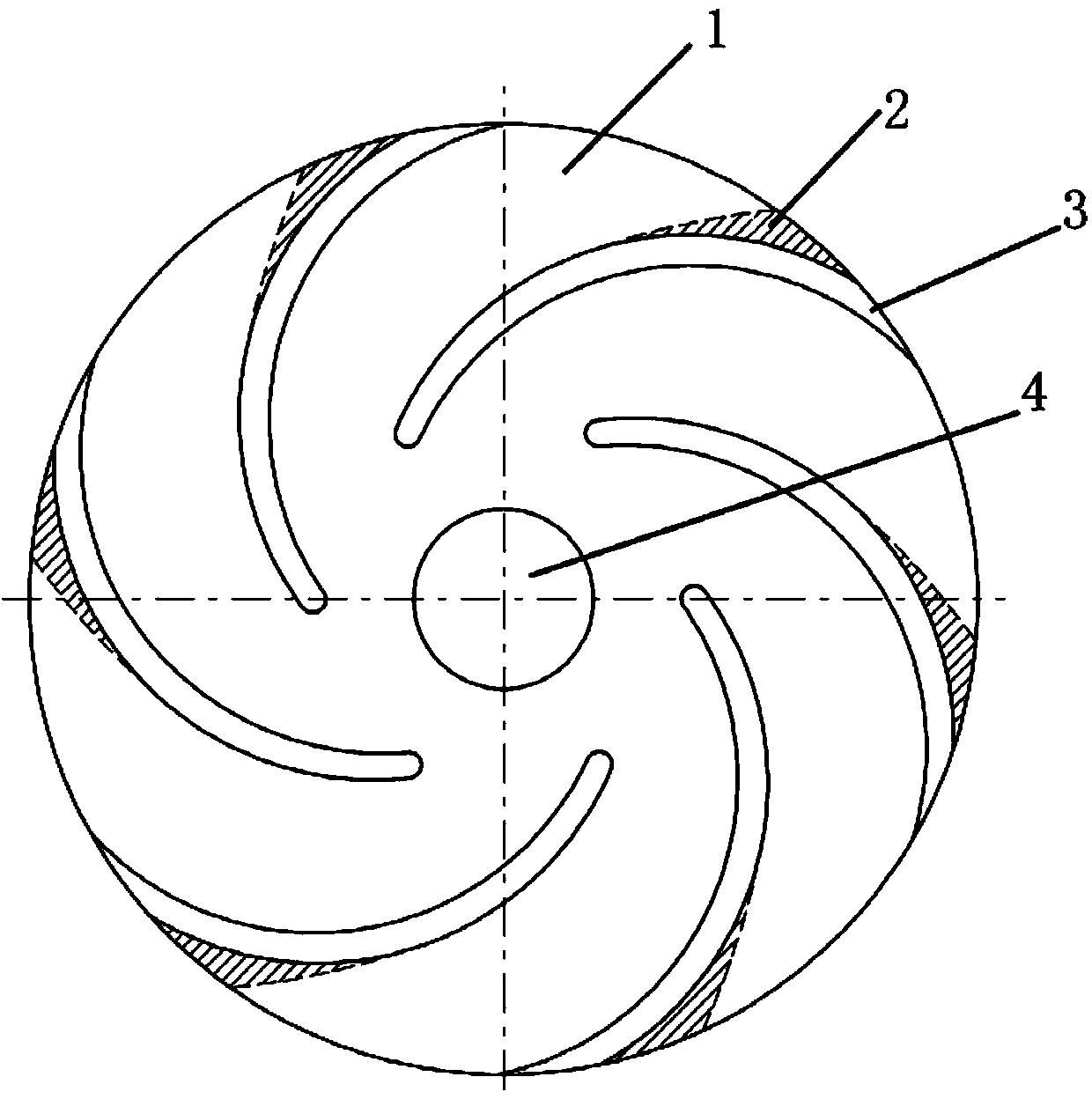

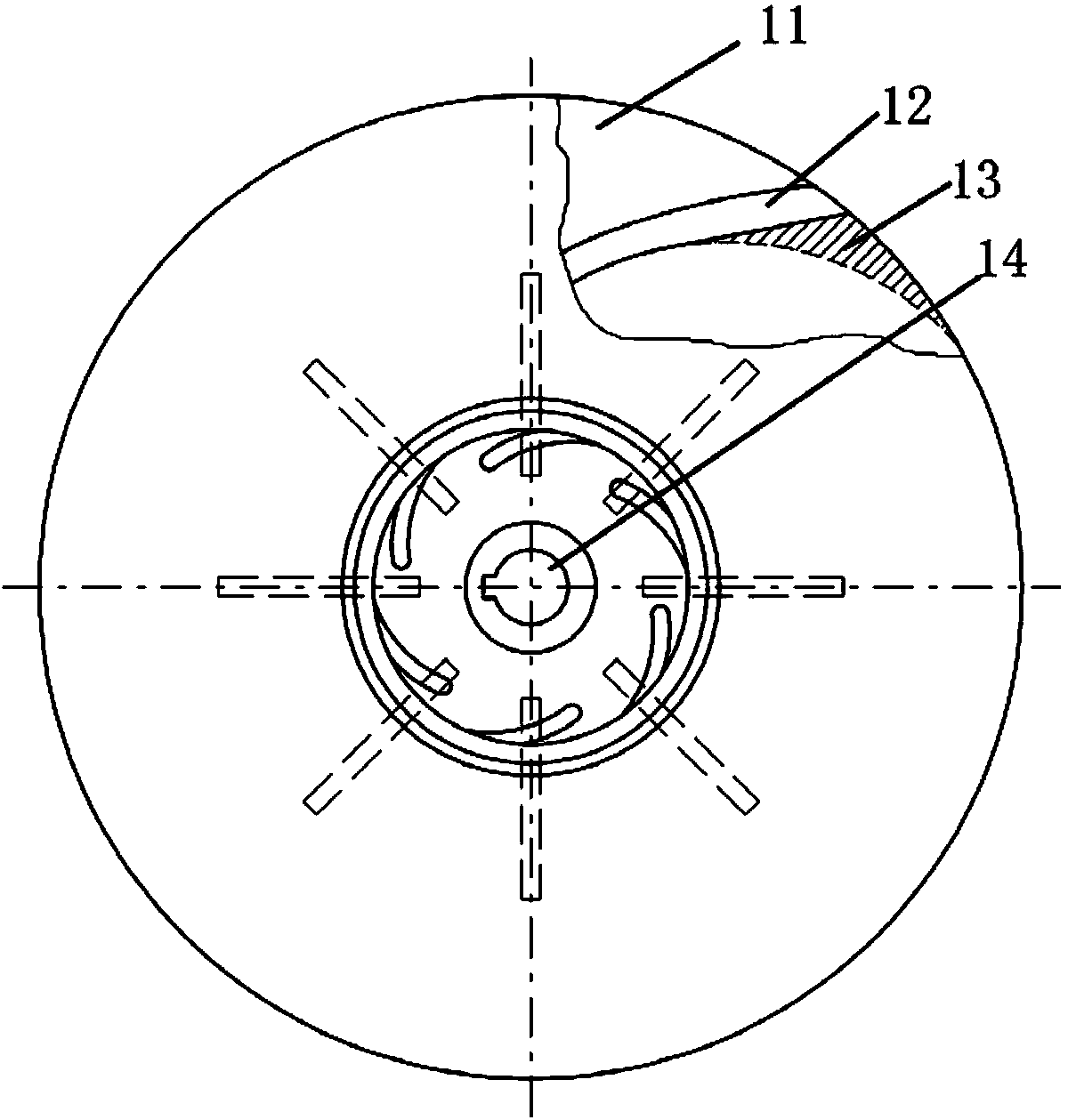

[0020] (1) if figure 1 As shown, select the specification and model of the pump according to the requirements, and select the impeller mold 1 according to the impeller according to the pump model specifications. The middle position of the impeller mold 1 is provided with a process boss 4. The block 2 has a certain thickness, and the inner side of the movable block 2 can be attached to the outlet edge of the working surface of the impeller mold blade 3; the material of the movable block 2 is wood or plastic.

[0021] (2) Fix the edge position of each impeller mold blade 3 to a loose block 2 to obtain a new ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com