Intermediate axle main reducer assembly provided with rear bevel gear engaging and disengaging mechanism

A technology of main reducer and clutch mechanism, which is applied in the direction of belt/chain/gear, gear lubrication/cooling, mechanical equipment, etc., and can solve the problems of difficult axial fixation and axial detachment of driven cylindrical gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A middle axle final reducer assembly with a rear bevel gear clutch mechanism according to the present invention will be described below in conjunction with the accompanying drawings.

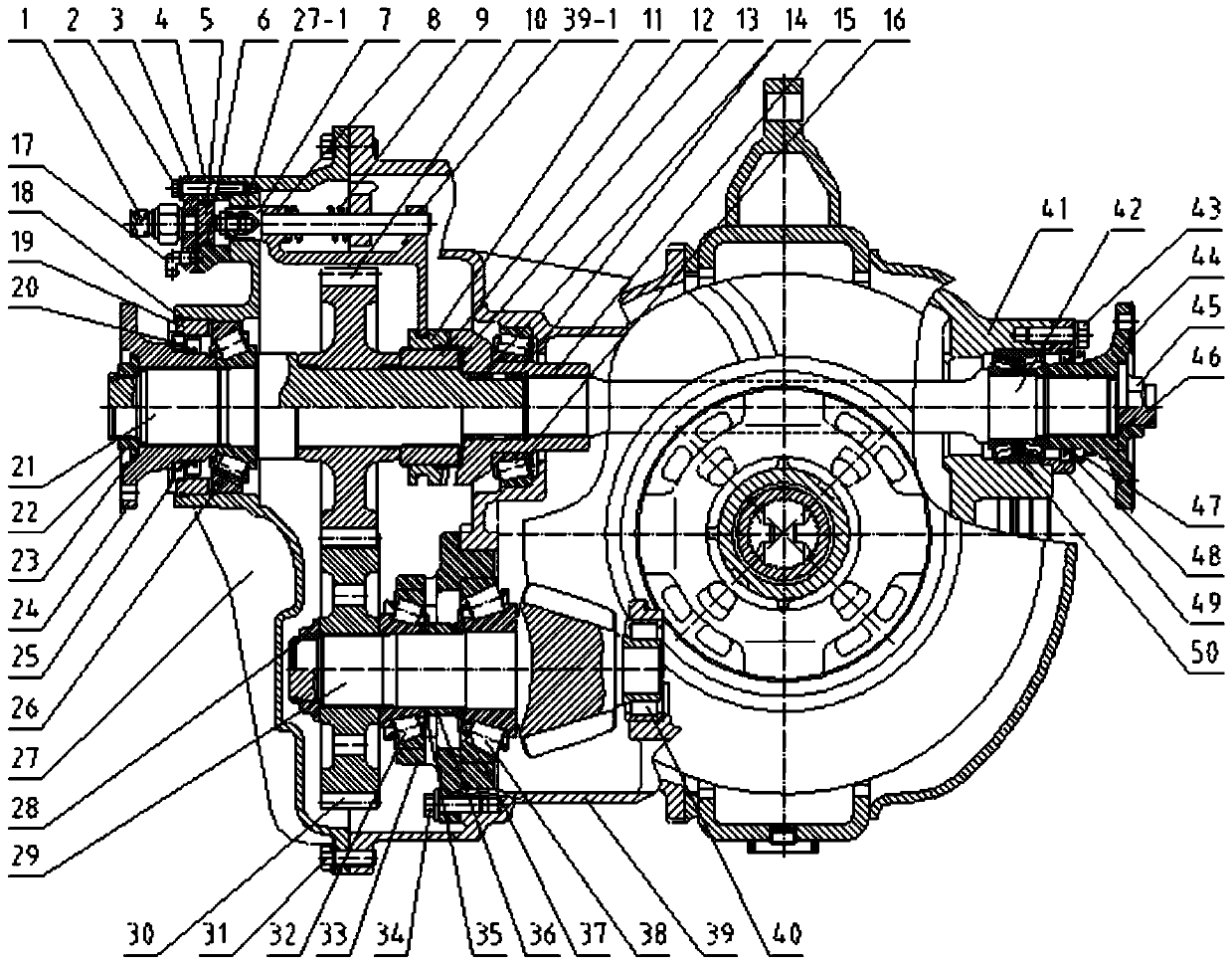

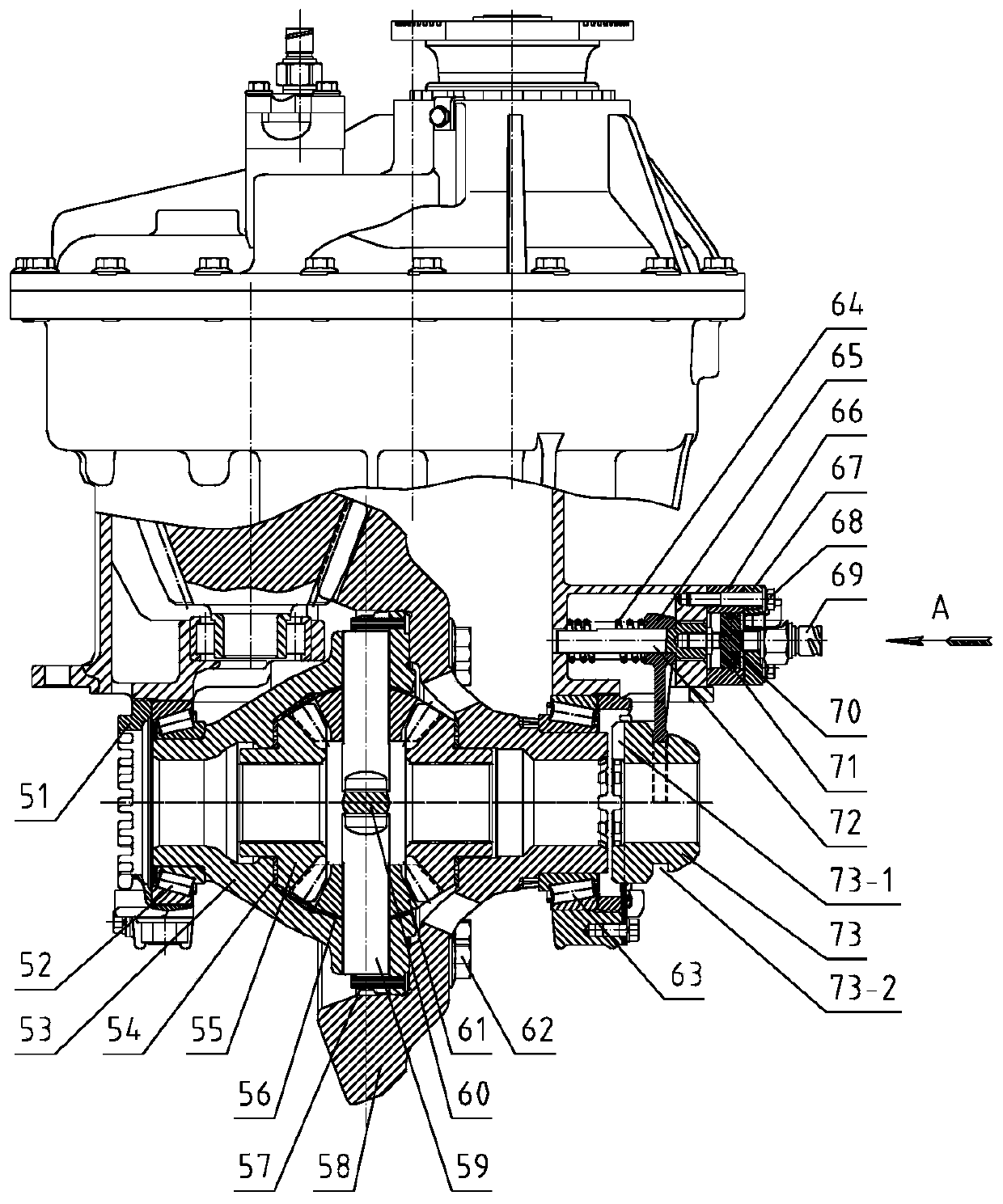

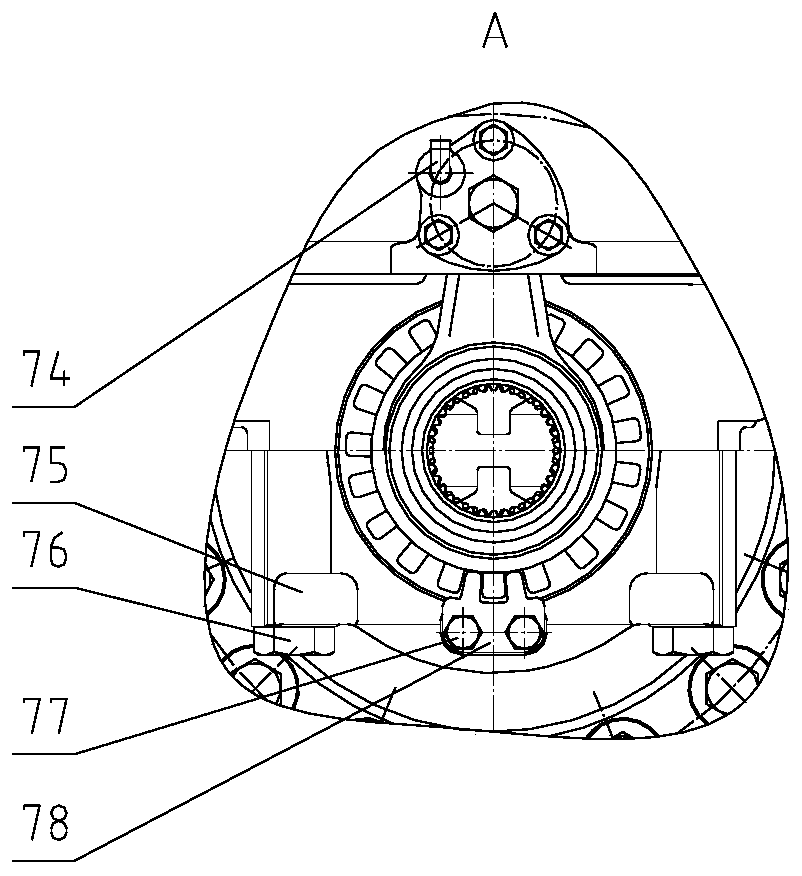

[0042] as attached Figure 1-Figure 5 As shown, a middle axle main reducer assembly with a rear bevel gear clutch mechanism consists of a rear bevel gear clutch mechanism assembly, a driving bevel gear assembly, a through-shaft assembly, an inter-wheel differential and The inter-wheel differential lock assembly is composed of parts.

[0043] Rear bevel gear clutch mechanism assembly consists of clutch differential lock switch (1), clutch differential lock cylinder head connecting bolt (2), clutch differential lock cylinder head (3), clutch differential lock cylinder (4), clutch Differential lock piston (5), clutch differential lock piston seal O-ring (6), clutch differential lock fork shaft (7), clutch differential lock fork (8), clutch differential lock return spring ( 9), driving cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com