Middle frame of liquid crystal display device and liquid crystal display device

A technology of a liquid crystal display device and a buffer part, which is applied in the field of middle frames and liquid crystal display devices, and can solve problems such as fragmentation, easy appearance of bright spots, and processing costs, and achieve the effects of high cost, long production cycle, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

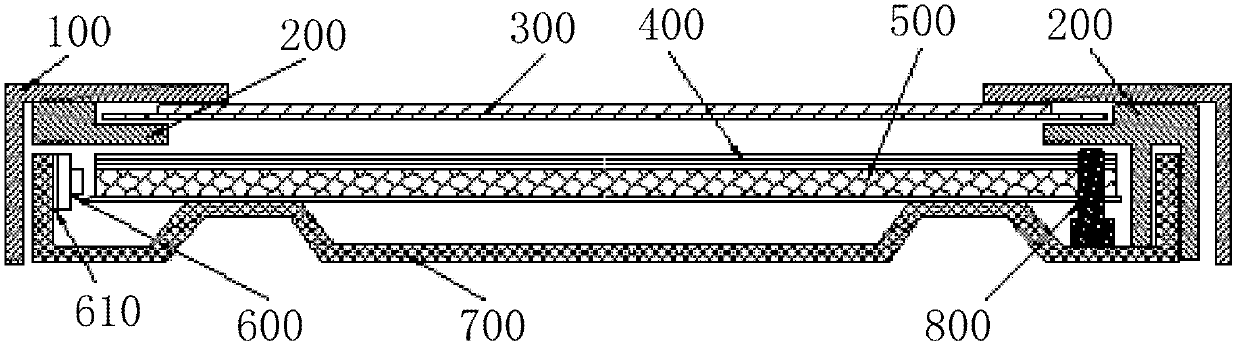

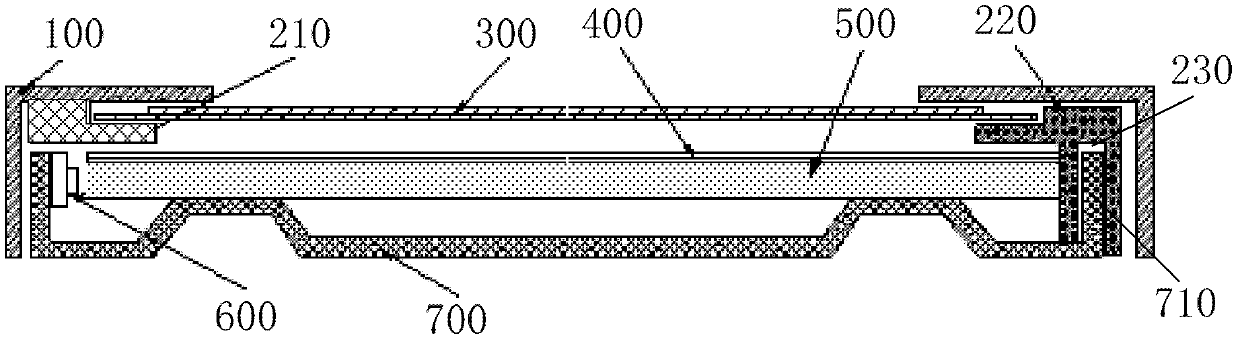

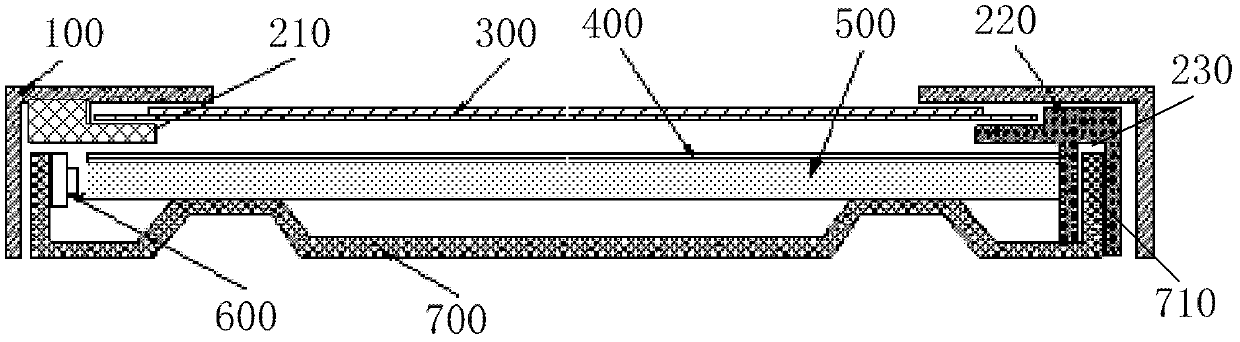

[0020] like figure 2 As shown, it includes a panel 300 and a backlight module, and the panel 300 and the backlight module are fixed by the front frame 100 . The backlight module includes a frame body composed of a middle frame 200 and a backplane 700 , the backplane 700 supports a light guide plate 500 , and the light emitting surface of the light guide plate 500 is covered with an optical film 400 . There is a folded edge 710 around the back plate 700 , and a light source component is provided at the position corresponding to the folded edge 710 on the light incident surface of the light guide plate 500 , and the light source component can be an LED light bar 600 . The above-mentioned middle frame 200 of a liquid crystal display device is fixed around the back plate 700 , and the middle frame 200 has an extension part spaced between the pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com