High-temperature-wear-resistant lining plate for coke pot for coke dry quenching and preparation method thereof

A high-temperature-resistant lining technology, which is applied in coke ovens, coke cooling, coating, etc., can solve the problems of short service life of coke tank linings, difficulty in realizing single-quality materials, and inability to meet continuous production, and achieve excellent performance , excellent wear resistance, and maintain the effect of small change in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) The prepared cermet powder is uniformly mixed by a three-dimensional powder mixer. The mass percentage of each component in the cermet powder is: C 0.25%, Si 0.35%, Cr 18%, Ni 32%, Al 40%, and the rest The amount is Fe; the particle size is 180 mesh;

[0049] (2) Use shot peening to remove scale and impurities on the surface of the 15CrMo heat-resistant steel plate metal lining; use a brush to evenly paint the light-absorbing paint—black carbon ink on the surface of the above metal lining, and the pre-coating thickness is 0.03 mm;

[0050] (3) Naturally air-dried carbon ink coating; adopt the method of pneumatic powder feeding, and the powder feeding volume is 4.0L / min;

[0051] (4) Under the protection of argon gas, the cermet powder is scanned by a 5kW high-power laser, the laser power is P=3500W, the spot diameter is 5mm, the overlap rate is 30%, and the scanning speed is V=500mm / min, and the alloy powder is clad on the metal Liner surface.

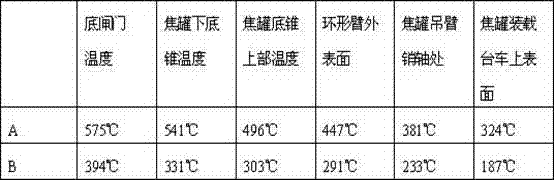

[0052] The CDQ cok...

Embodiment 2

[0054] (1) Mix the prepared cermet powder uniformly through a V-type powder mixer. The mass percentage of the cermet powder is: C 0.2%, Si 1.2%, Cr 15%, Ni 25%, Al 35%, and the balance is Fe, the particle size of cermet powder is 180 mesh;

[0055] (2) Remove the scale on the surface of the cast steel 40Mn2 metal liner with a grinder; use a brush to evenly paint the black carbon ink light-absorbing paint on the surface of the metal liner, and the pre-coating thickness is 0.03mm;

[0056] (3) Naturally air-dry the carbon ink coating; then adopt the method of pneumatic powder feeding, and the powder feeding volume is 3.3L / min;

[0057] (4) Under the protection of argon gas, the cermet powder is scanned by a 5kW high-power laser, the laser power is P=3200W, the spot diameter is 5mm, the overlap rate is 30%, and the scanning speed is V=450mm / min, and the cermet powder is clad on Metal backing surface.

[0058] The CDQ coke pot high-temperature-resistant wear plate prepared by th...

Embodiment 3

[0060] (1) The prepared cermet powder is evenly mixed by a planetary ball mill mixer. The mass percentage of the cermet powder is: C 0.15%, Si 0.75%, Cr 20%, Ni 33%, Al 30%, and the balance is Fe , the particle size of the cermet powder is 180 mesh;

[0061] (2) Use sandpaper to remove the scale on the surface of the ZG35CrMo metal lining; use a brush to evenly paint the black carbon ink light-absorbing paint on the surface of the metal lining, and the pre-coating thickness is 0.05mm;

[0062] (3) Dry the carbon ink coating with a blower; adopt the method of gravity powder feeding, and the powder feeding amount is 3.0L / min;

[0063] (4) Under the protection of argon gas, the metal powder is scanned by a 5kW high-power laser, the laser power P=3300W, the spot diameter is 5mm, the overlap rate is 40%, and the scanning speed V=450mm / min, the cermet powder is clad on the metal Liner surface.

[0064] The CDQ coke tank high-temperature wear-resistant plate prepared by the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com