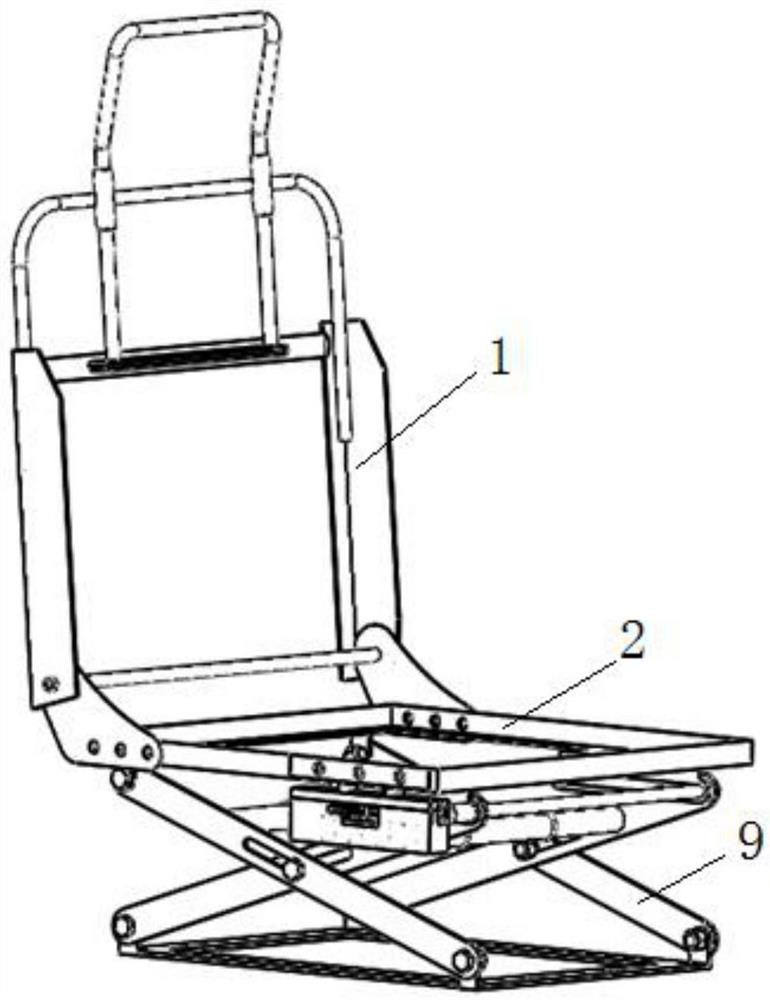

A tank driver lift chair with high position compensation

A driver and lift chair technology, which is applied in the field of tank driver lift chairs, can solve problems such as the driver's difficulty in stepping on the pedals, and achieve the effects of stable structure, time saving and increased time reserve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

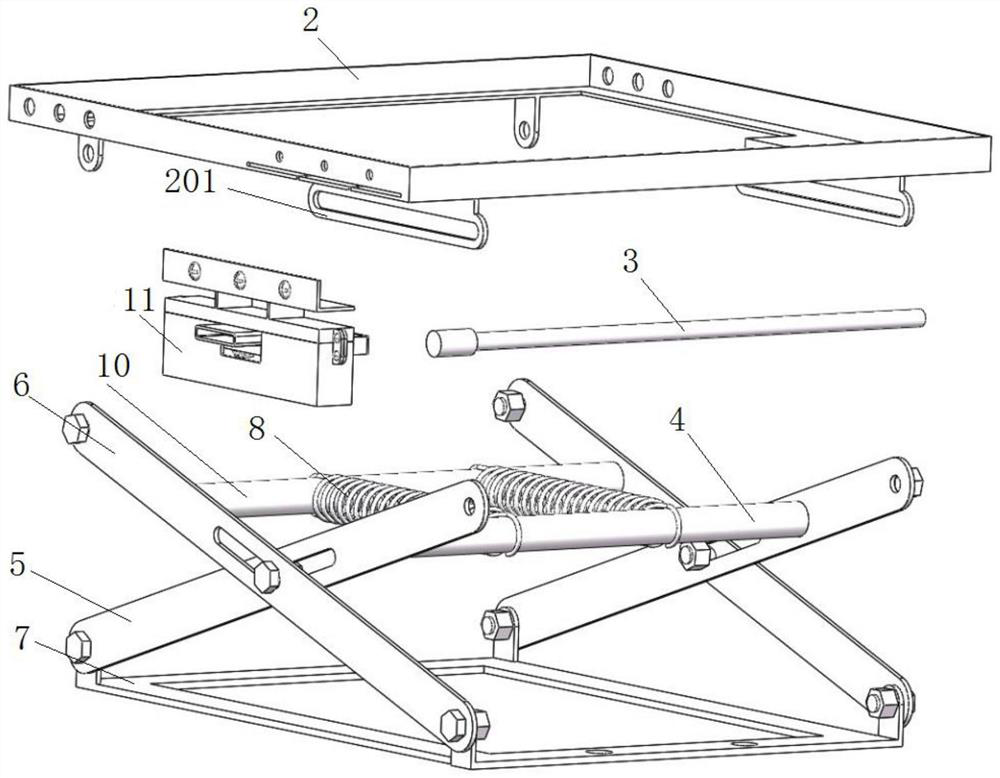

[0032] like Figure 7 and Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the locking mechanism is an electric locking mechanism, and the electric locking mechanism includes a rack 22, a photosensitive sensor 23, a controller 24, a gear 25, a motor 26 and Control button 27; the motor 26 is installed on the beam on one side of the long slideway 201 of the seat cushion frame 2, and the end of the output shaft of the motor 26 is provided with a gear 25, and the gear 25 passes through the through hole on the beam and is provided with a The rack 22 meshed with it, the rack 22 is fixed on the end of the slide bar 3, the controller 24, the photosensitive sensor 23, the control button 27 and the motor 26 are all arranged at the same horizontal position, and the controller 24 is close to the frame of the seat cushion 2; the photosensitive sensor 23 and the control button 27 are all arranged on the outside of the seat cushion frame 2, and are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com