Method for repairing and reinforcing fluid transportation pipeline without stopping production

A fluid transportation and pipeline technology, applied in the field of non-stop repair and reinforcement of fluid transportation pipelines, can solve problems affecting repair quality, pipe body deformation, cold brittleness, etc., to improve work efficiency, avoid fire and explosion, and shorten the repair period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

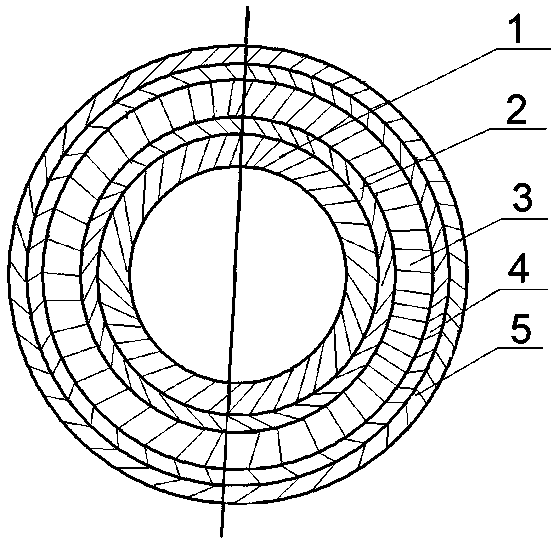

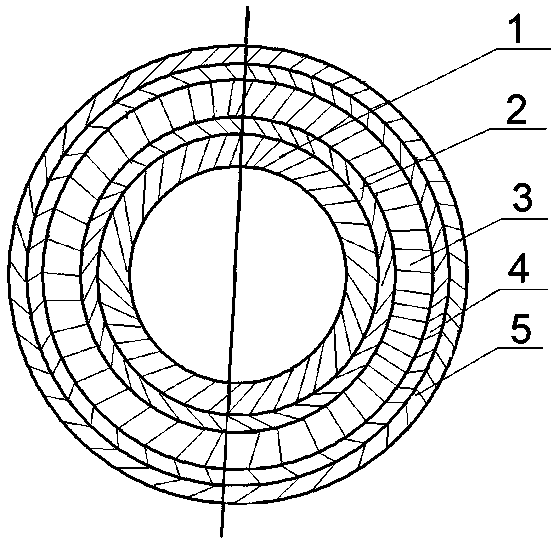

[0026] see figure 1 , a method for non-stop production repair and reinforcement of a fluid delivery pipeline, the specific steps are as follows:

[0027] 1) Detect the defect position and size of the pipeline 1;

[0028] 2) Use all-metal plugging technology for the pipeline to do metal pressure plugging and repair on the perforated part, so that the surface to be repaired becomes a continuous metal surface, clean the surface of the part to be repaired in the pipeline 1, and use sandblasting to remove rust or explosion-proof The derusting machine removes rust, removes scale, loose rust, old coatings and dirt. After surface cleaning, the surface cleanliness reaches Sa3 level, and the surface roughness reaches Ry40-130μm;

[0029] 3) Apply 120 sizing agent to the part of the pipeline 1 to be repaired, and use the super metal repair agent to repair the perforation of the pipeline 1 and repair the parts that have lost strength due to corrosion and convexity. After natural curing, ...

Embodiment 2

[0034] see figure 1 , a method for non-stop production repair and reinforcement of a fluid delivery pipeline, the specific steps are as follows:

[0035] 1) Detect the defect position and size of the pipeline 1;

[0036] 2) Use all-metal plugging technology for the pipeline to do metal pressure plugging and repair on the perforated part, so that the surface to be repaired becomes a continuous metal surface, clean the surface of the part to be repaired in the pipeline 1, and use sandblasting to remove rust or explosion-proof The derusting machine removes rust, removes scale, loose rust, old coatings and dirt. After surface cleaning, the surface cleanliness reaches Sa3 level, and the surface roughness reaches Ry40-130μm;

[0037] 3) Apply 120 sizing agent to the part of the pipeline 1 to be repaired, and use the super metal repair agent to repair the perforation of the pipeline 1 and repair the parts that have lost strength due to corrosion and convexity. After natural curing, ...

Embodiment 3

[0042] see figure 1 , a method for non-stop production repair and reinforcement of a fluid delivery pipeline, the specific steps are as follows:

[0043] 1) Detect the defect position and size of the pipeline 1;

[0044]2) Use all-metal plugging technology for the pipeline to do metal pressure plugging and repair on the perforated part, so that the surface to be repaired becomes a continuous metal surface, clean the surface of the part to be repaired in the pipeline 1, and use sandblasting to remove rust or explosion-proof The derusting machine removes rust, removes scale, loose rust, old coatings and dirt. After surface cleaning, the surface cleanliness reaches Sa3 level, and the surface roughness reaches Ry40-130μm;

[0045] 3) Apply 120 sizing agent to the part of the pipeline 1 to be repaired, and use the super metal repair agent to repair the perforation of the pipeline 1 and repair the parts that have lost strength due to corrosion and convexity. After natural curing, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com