Pumping unit balance adjusting apparatus and pumping unit balance structure adjusting method

A technology of balance adjustment and pumping unit, which is applied in the testing of machine/structural components, static/dynamic balance testing, instruments, etc., and can solve the problems of narrow application area, waste of electric energy, and few functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

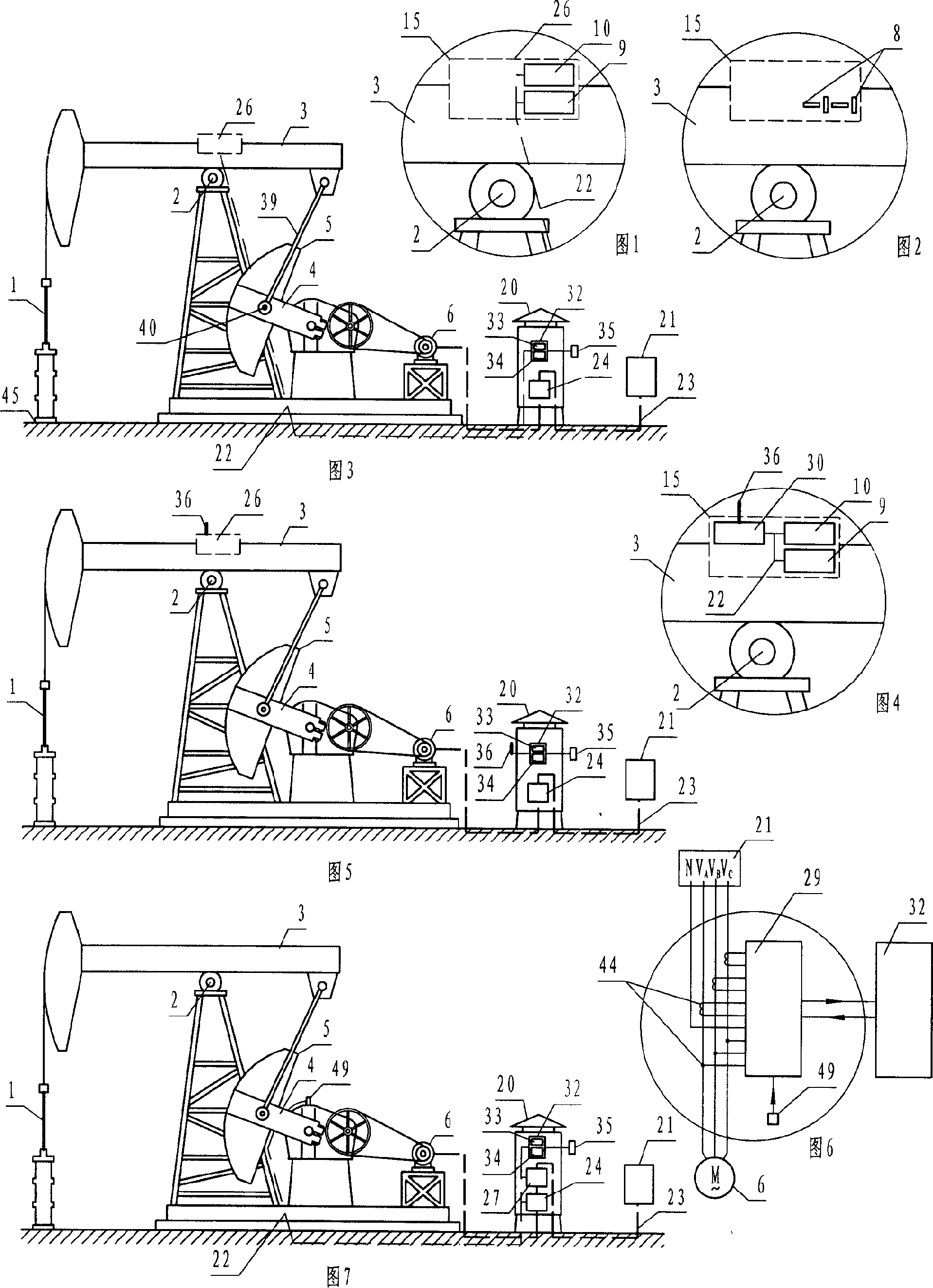

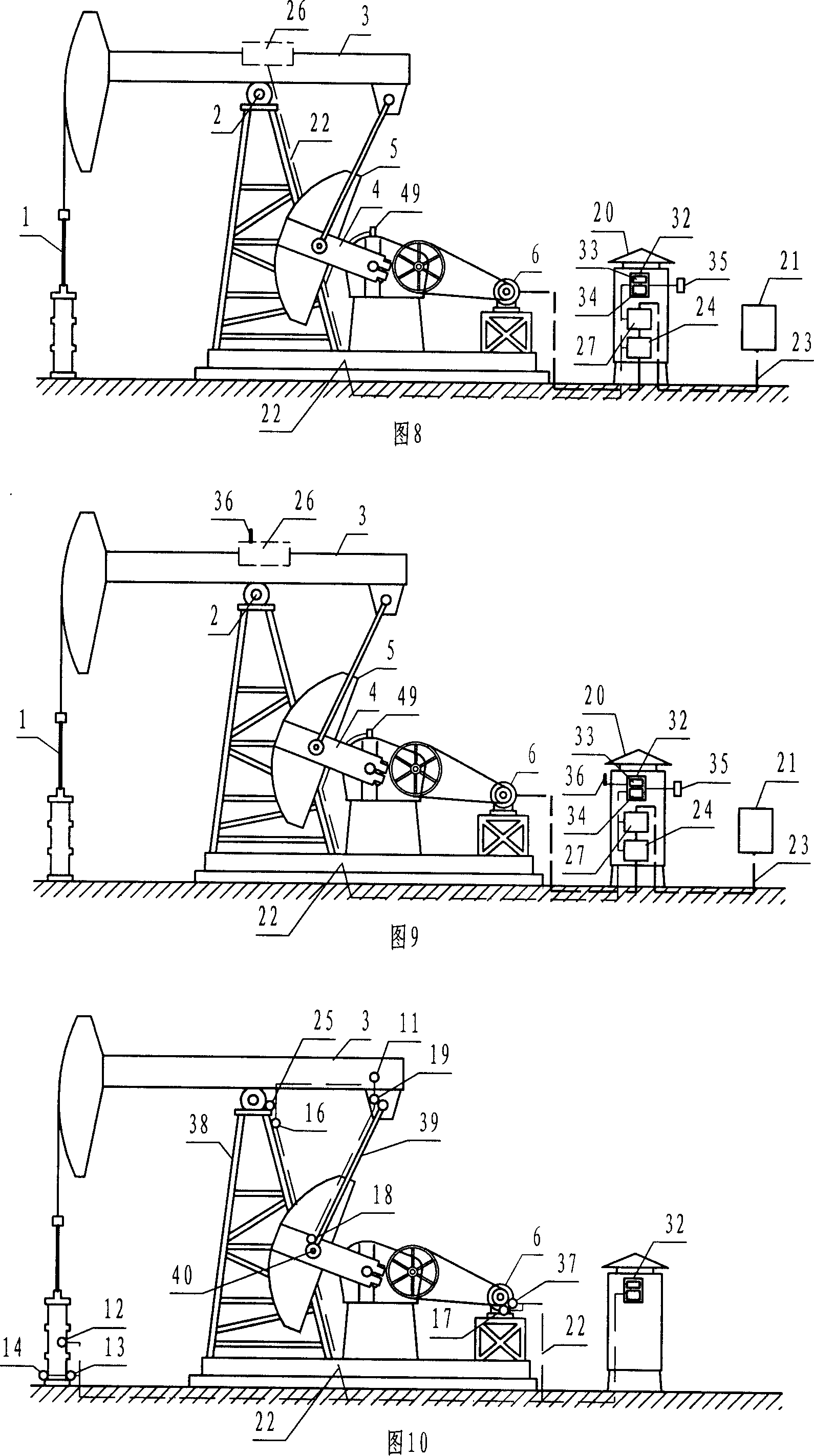

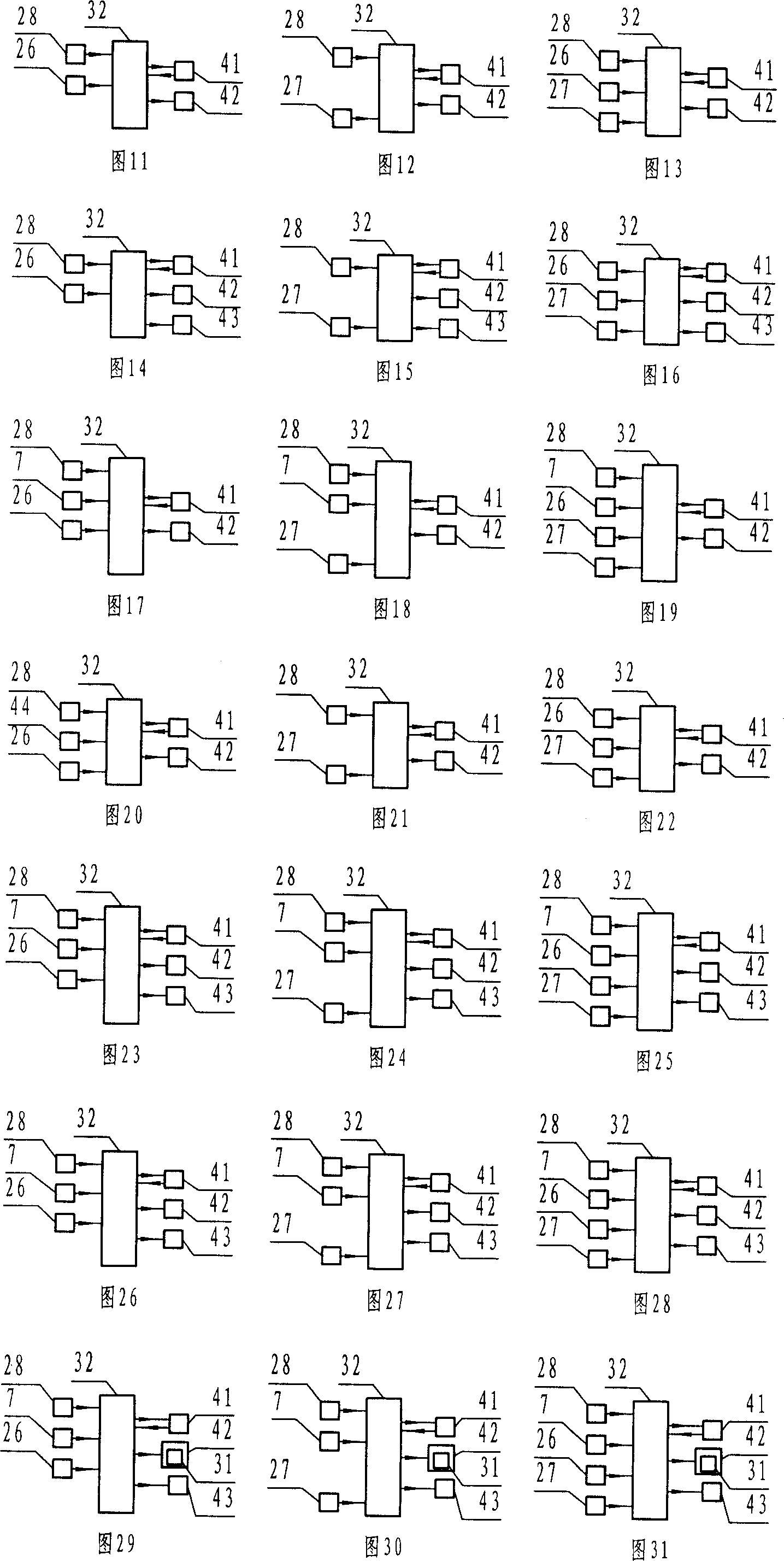

[0161] Embodiment 1, as shown in Figure 11, belongs to a pumping unit balance regulator adopting a "beam structure for displaying work".

[0162] It consists of a data input device 28, a beam display structure 26, a central processing unit 32, a storage device 41, an output device 42, etc., and its working process is as follows:

[0163] The parameters obtained by the data input device 28 and the beam display structure 26 are transmitted to the central processing unit 32, and the central processing unit 32 obtains "adjustment direct parameters" through data processing, and is transmitted to the storage device 41 for storage and transmitted to the The output device 42 displays.

Embodiment 2

[0164] Embodiment 2, as shown in Figure 12, belongs to a pumping unit balance regulator adopting an "electrical power indicator structure".

[0165] It consists of a data input device 28, an electric power indicator structure 27, a central processing unit 32, a storage device 41, an output device 42, etc., and its working process is as follows:

[0166] The parameters obtained by the data input device 28 and the electric indicator structure 27 are transmitted to the central processing unit 32, and the central processing unit 32 obtains "adjustment direct parameters" through data processing, and transmits to the storage device 41 for storage, and transmits to the The output device 42 displays.

Embodiment 3

[0167] Embodiment 3, as shown in Figure 13, belongs to a pumping unit balance regulator adopting a "complementary structure".

[0168] It consists of a data input device 28, a beam indicator structure 26, an electric indicator structure 27, a central processing unit 32, a storage device 41, an output device 42, etc. Its working process is as follows:

[0169] The parameters obtained by the data input device 28, the beam display structure 26, and the electric display structure 27 are transmitted to the central processing unit 32, and the central processing unit 32 obtains the "thinning control" through "complementary comprehensive processing" of the data. parameters", transmitted to the storage device 41 for storage, and transmitted to the output device 42 for display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com