Cutting pick, cutting pick head and manufacturing method thereof

A manufacturing method and the technology of the pick head, applied in the direction of manufacturing tools, earth drilling, furnace types, etc., can solve the problem of alloy material hardness, insufficient wear resistance, inability to protect the pick main body, picks and pick heads Solve problems such as overall scrapping, and achieve the effect of strong wear resistance, simple structure and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

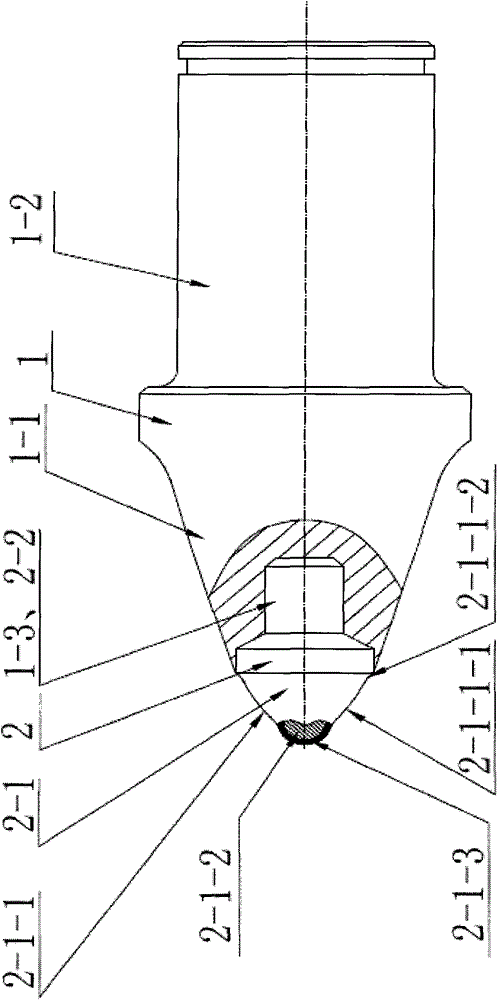

[0020] A pick 1 and a pick head 2. The pick head 2 is welded to the end of the body of the pick 1, and the body of the pick 1 is provided with a tapered section 1-1 and a cylindrical connecting rod section 1-2. One end of the tapered section 1-1 is provided with an axial blind hole 1-3, and the axial blind hole 1-3 is used to connect the pick head 2; the working section 2-1 and the connecting section 2 are provided on the pick head 2 -2, the connecting section 2-2 is inserted into the axial blind hole 1-3. The working section of the pick head 2 is provided with two parts, a conical curved surface section 2-1-1 and a spherical top 2-1-2, and a diamond layer 2-1 is provided on the spherical top 2-1-2 -3. Smooth transitional connection between the diamond layer 2-1-3 and the conical curved surface section 2-1-1.

Embodiment 2

[0022] On the basis of Embodiment 1, a preferred embodiment of the present invention is to control the thickness of the diamond layer 2-1-3 to be between 2 mm and 4 mm, and the rest is completely the same as Embodiment 1.

Embodiment 3

[0024] On the basis of embodiment 2, the preferred embodiment of the present invention is that the conical curved surface section 2-1-1 consists of a convex curved conical section 2-1-1-1 and a concave curved conical section 2-1-1. 2 is composed of two parts, the convex curved conical section 2-1-1-1 and the concave curved conical section 2-1-1-2 smoothly transition, the convex curved conical section 2-1-1 One end is smoothly connected to the diamond layer 2-1-3, and one end of the concave curved conical section 2-1-1 is connected to the connecting section 2-2 on the pick head 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com