Manganese ore pulp stirring paddle with long service life

A stirring paddle, long-life technology, applied in the field of stirring paddle, can solve the problems of high total production cost, increase the weight of the paddle, increase the load of the motor, etc., achieve the effect of reducing the total production cost, small motor load, and reducing the loss of production stoppage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

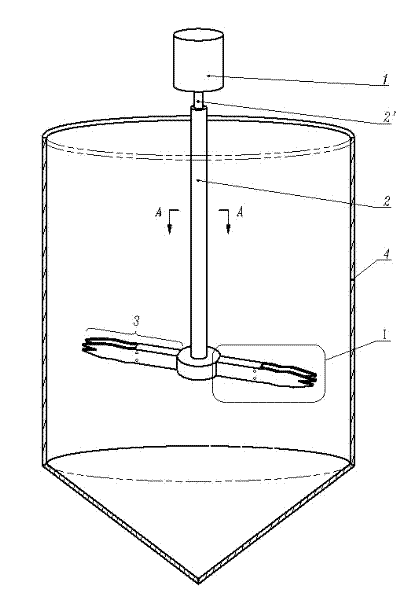

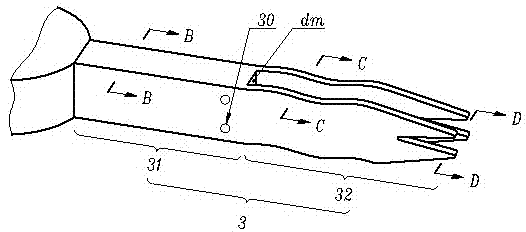

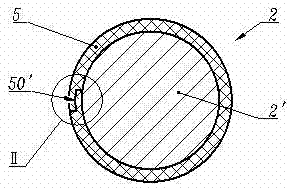

[0015] Manganese ore slurry stirring paddle with long service life (refer to figure 1 , 2 , 3, 4, 5), the stirring paddle includes a stirring shaft, a stirring paddle connected to the stirring shaft and submerged in the manganese ore slurry. In the present invention, the outer surfaces of the stirring shaft 2' and the stirring paddles all have an isolation layer 5 covered by neoprene or natural rubber.

[0016] So far, those skilled in the art can combine the analysis and understanding of the beneficial effects of the present invention, according to different conditions or specific requirements, adopt different specific measures to make the corresponding stirring shaft 2, stirring blade 3, etc. are lightweight Stirring paddles with thickened materials (for the clarity of the picture, figure 1 It is only drawn according to the single-layer, two-blade stirring paddle 3 structure).

[0017] The measure in this specific embodiment is to adopt sticking process, that is: said iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com