High precision all-purpose autogiro and composing method thereof

A high-precision, gyroscope technology, applied in theodolite, steering sensing equipment, etc., can solve the problems of measurement alarm invalidation, high-precision difficulty, and orientation accuracy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

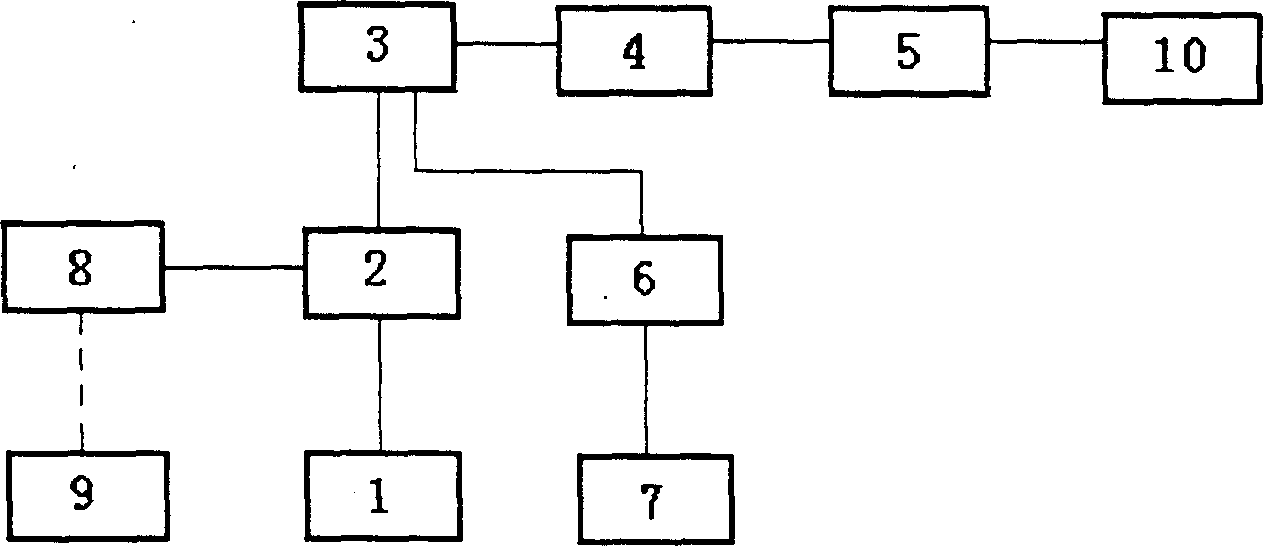

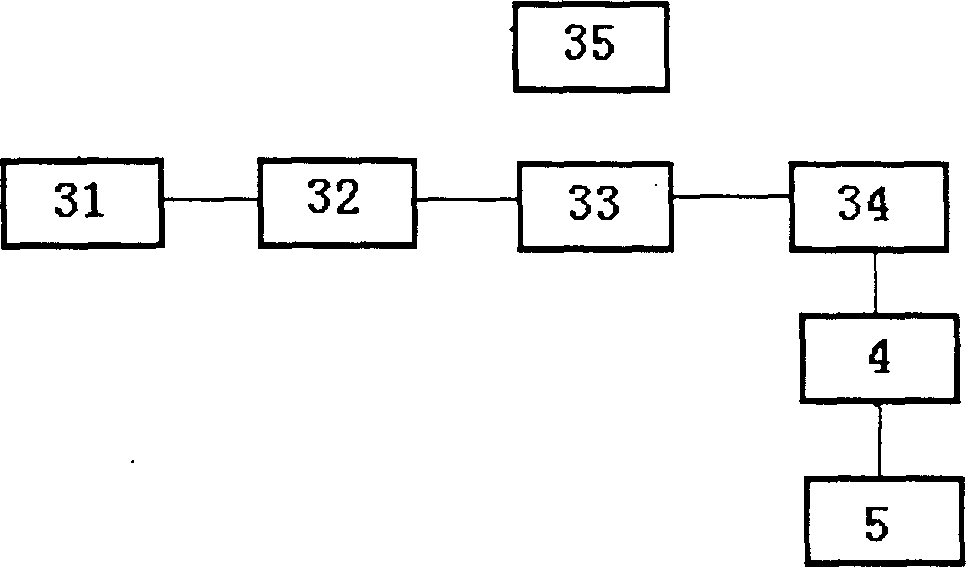

[0133]Based on the GAK-I gyro theodolite of the Swiss Wild company, it is transformed into a high-precision automatic gyro 3 of ± 5 seconds; the automatic gyro 3 is fixed through the threaded connector 2 fixed on the bracket of the automatic tracking electronic total station TCA2003; The original cursor is replaced by a double-shaped cursor 31 on the internal optical path; three gratings 32 and silicon photocells 33 are fixed below the original reticle, so that the three midlines of the grating and the -2.85, 0, +2.85 reticles on the reticle The positions are consistent; the signal output from the silicon photocell is drawn out on the upper platform of the automatic gyroscope 3 through a very thin shielding wire; a circuit board is fixed on the platform, and the photoelectric signal processor 34 is installed on the board; the output from the photoelectric signal processor The timing trigger signal is connected to a RS232 standard 9-pin plug; the 9-pin RS232 serial communication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com