Rotary kiln masonry structure

A masonry structure and rotary kiln technology, applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of damage, easy damage of refractory bricks, crushing and other problems, so as to improve the service life, reduce the frequency of masonry, connect firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

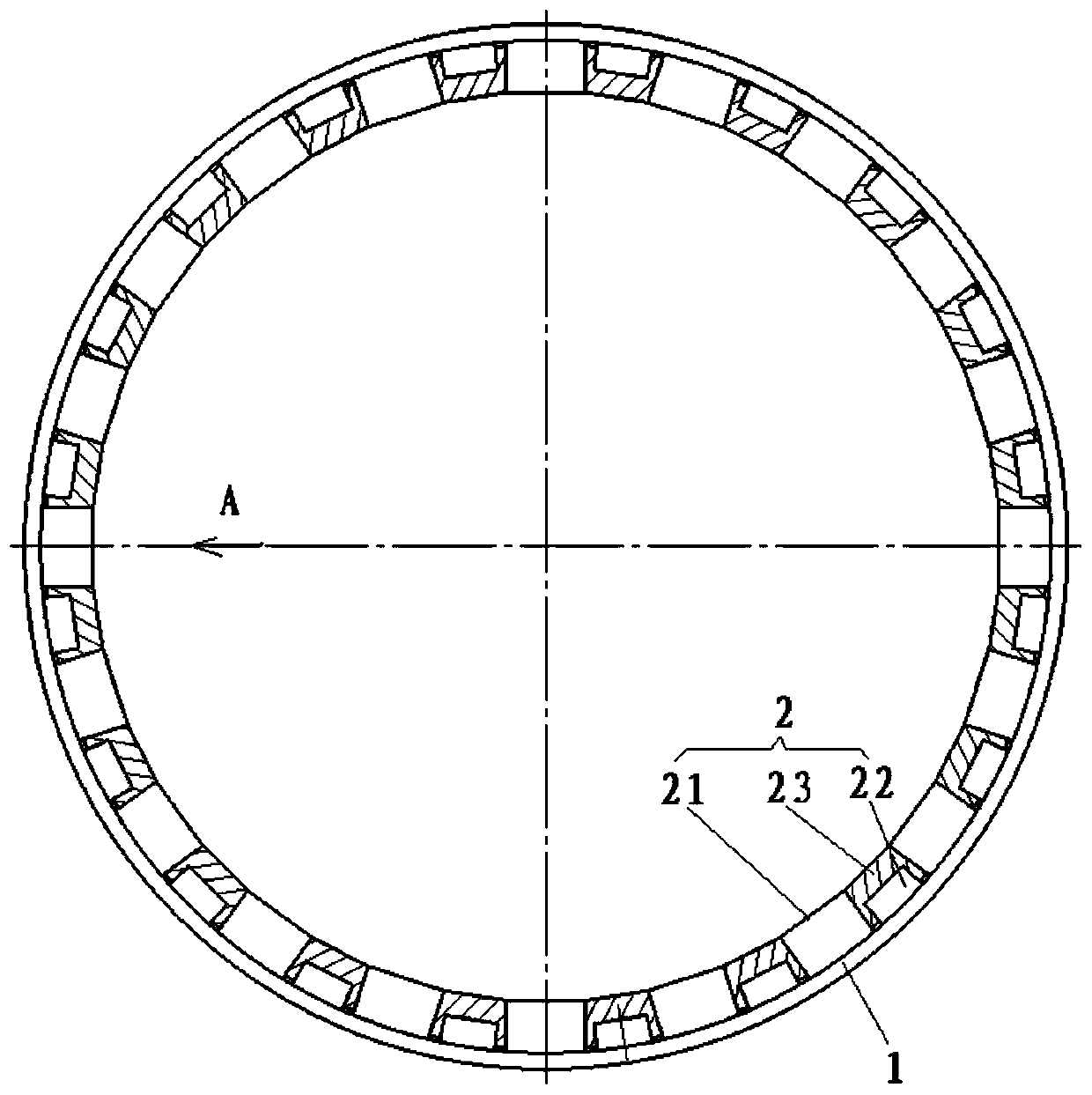

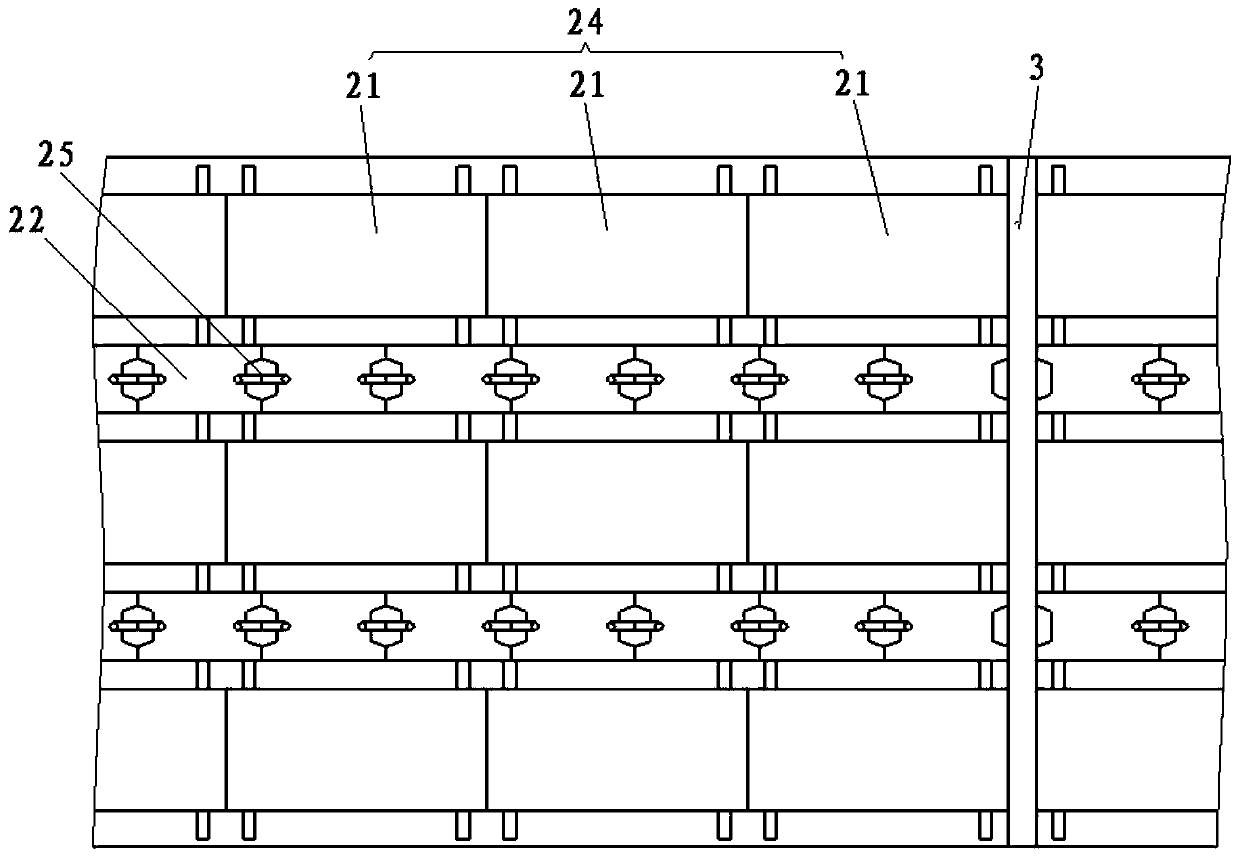

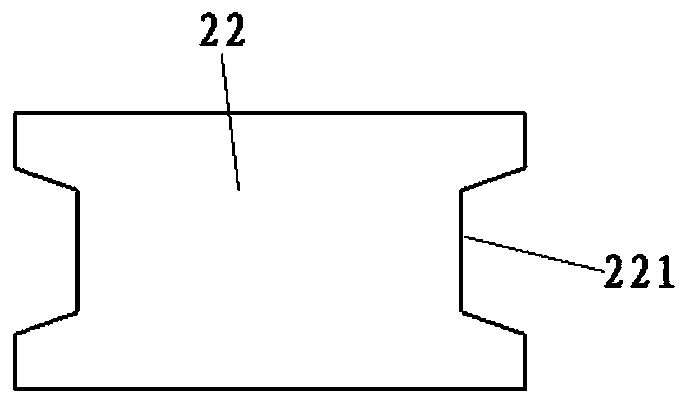

[0015] In order to provide an indestructible rotary kiln masonry structure, such as Figure 1 to Figure 5 As shown: the masonry structure of the rotary kiln includes the rotary kiln shell 1 and the masonry structure 2 arranged in the rotary kiln shell 1; it also includes the retaining brick ring 3; the masonry structure 2 includes refractory insulation bricks 21 and bottoming bricks 22 and fixed steel bars 25; refractory insulation bricks 21 are built along the length direction of the rotary kiln cylinder 1 to form a plurality of refractory insulation brick columns 24, each refractory insulation brick column 24 is a circular array with the axis of the rotary kiln cylinder 1 as the center, and the refractory insulation bricks 21 It includes the refractory heat insulation brick main body 211 and the connecting steel bar 212 arranged at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com