Full-automatic three-primary shaft combined lathe

A combined lathe, fully automatic technology, applied in the field of machine tools, can solve the problems of low production efficiency, poor precision stability, large occupied space, etc., and achieve the effects of improved efficiency, high production efficiency, and reduced occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

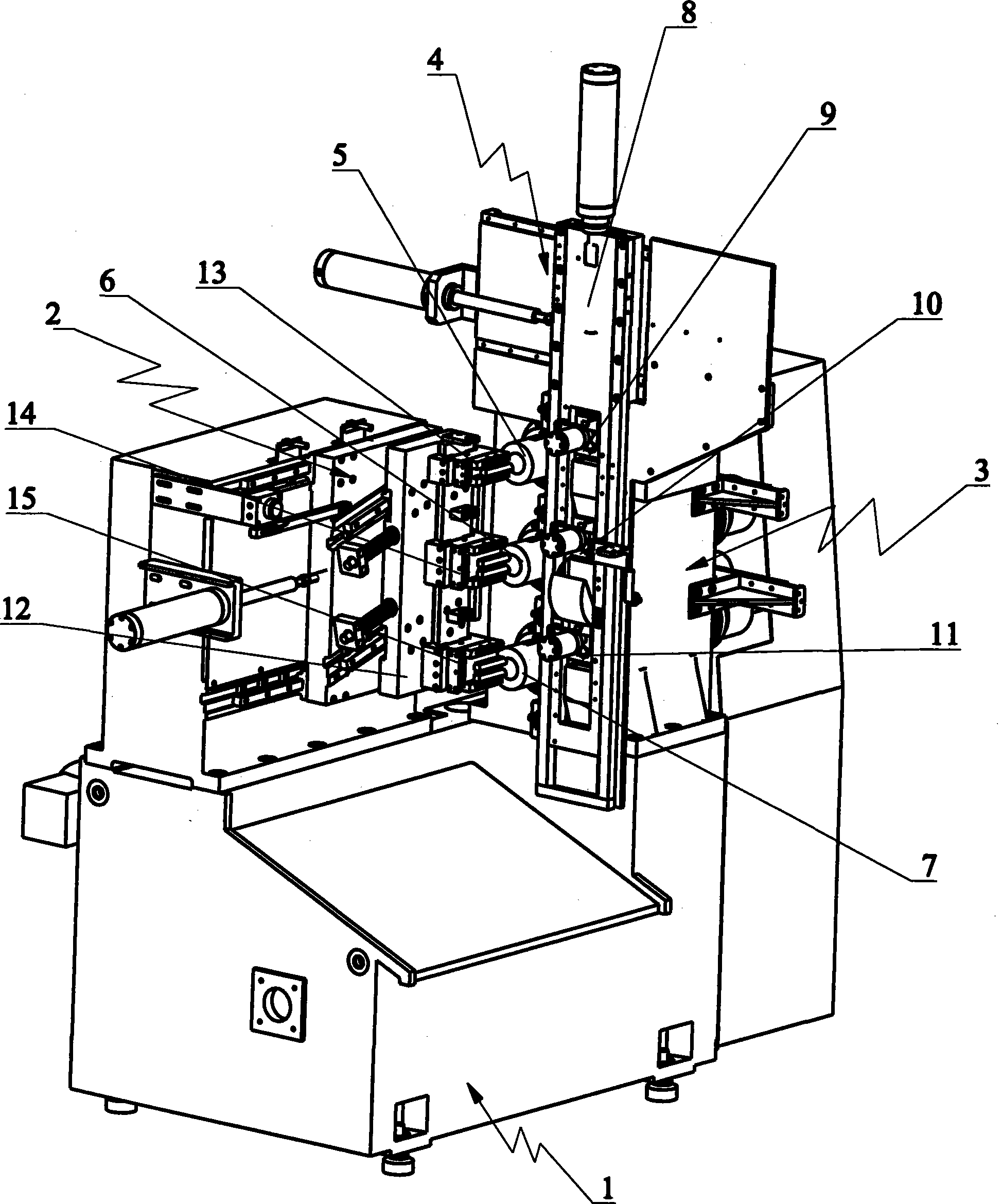

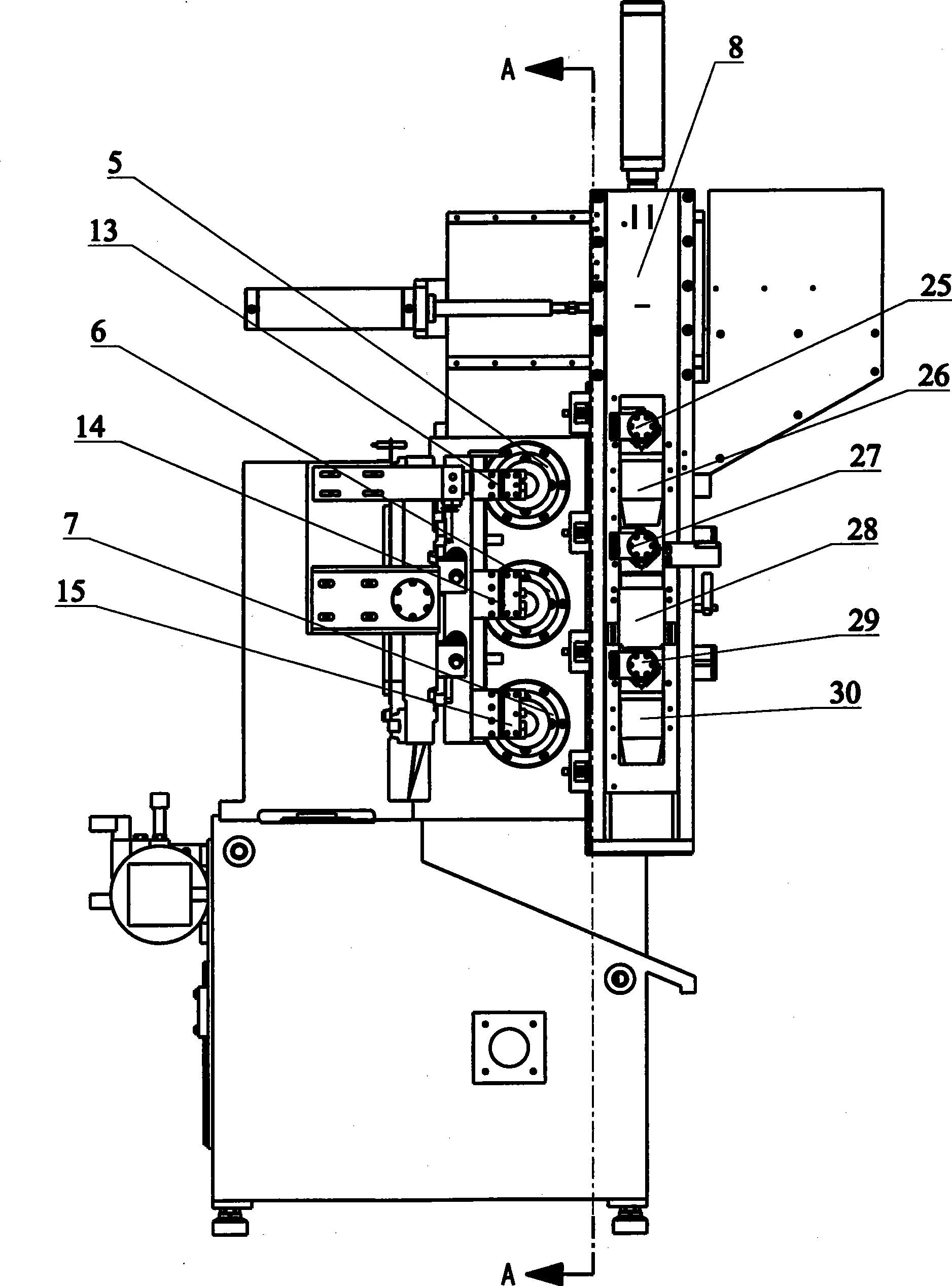

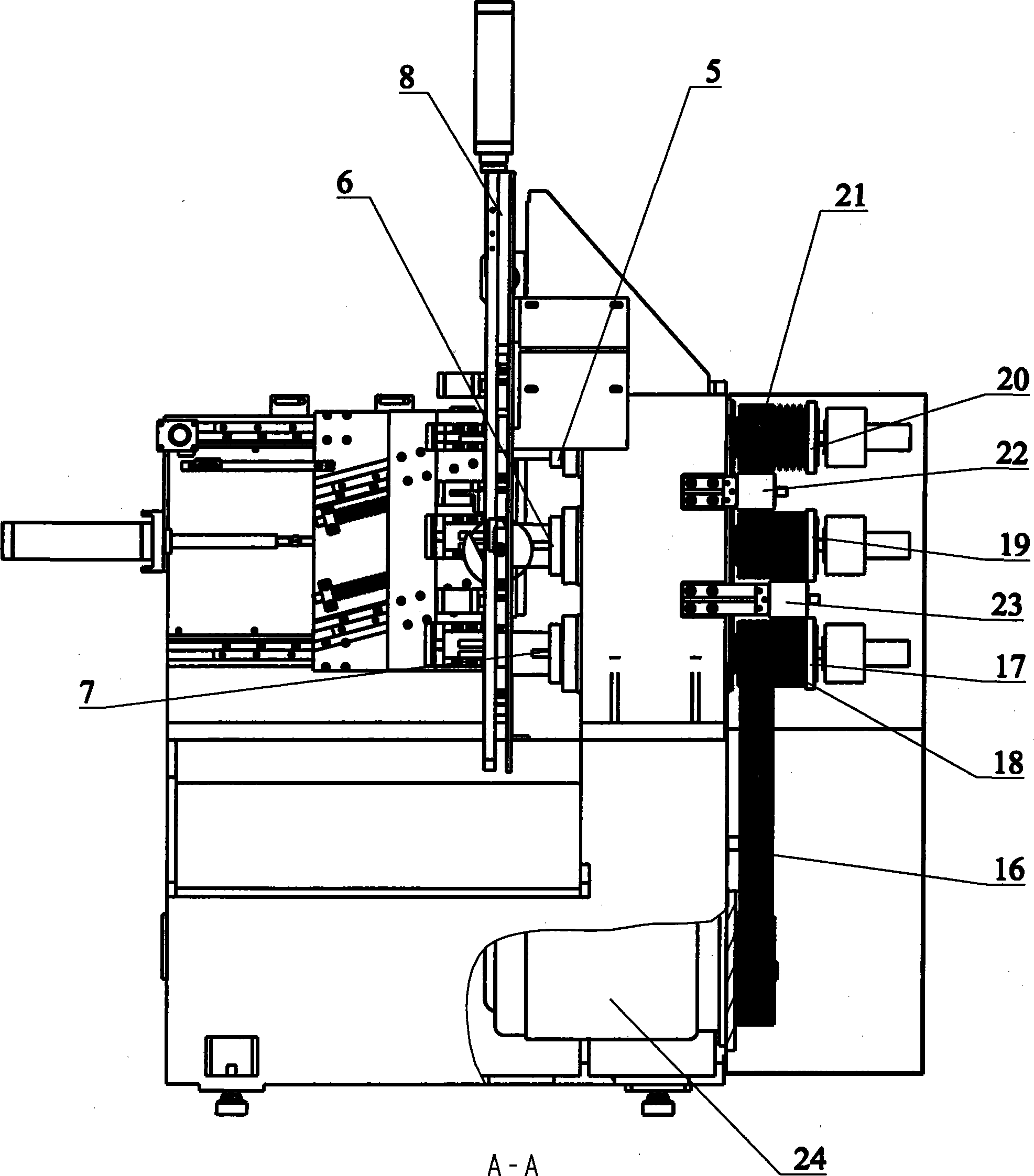

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , figure 2 , image 3 As shown, the present invention comprises bed 1, spindle box 3, feed mechanism 2, automatic loading and unloading mechanism 4, power motor 24, and spindle box 3, feed mechanism 2 are respectively fixedly installed on the right end of bed 1 upper surface and At the rear end, the automatic loading and unloading mechanism 4 is installed on the box body of the headstock 3; the headstock 3 is provided with three common spindle devices 5, 6, 7 from top to bottom in the Y-axis direction of the machine tool, and the spindle device 5 is provided with a pulley 20. The main shaft device 6 is provided with a pulley 19, the main shaft device 7 is provided with a pulley 17, the belt 21 is set on the pulleys 20, 19 and tensioned by the tension pulley 22, and the belt 18 is set on the pulleys 19, 17 and used by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com