Large deep/dameter ratio dentiform female die numerically-controlled electric spark expanding and processing device and processing method thereof

A technology of processing device and numerical control device, which is applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of processing internal and external helical gears and their molds that have not been reported, and achieves expanded processing versatility, a clean working environment, smooth looping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

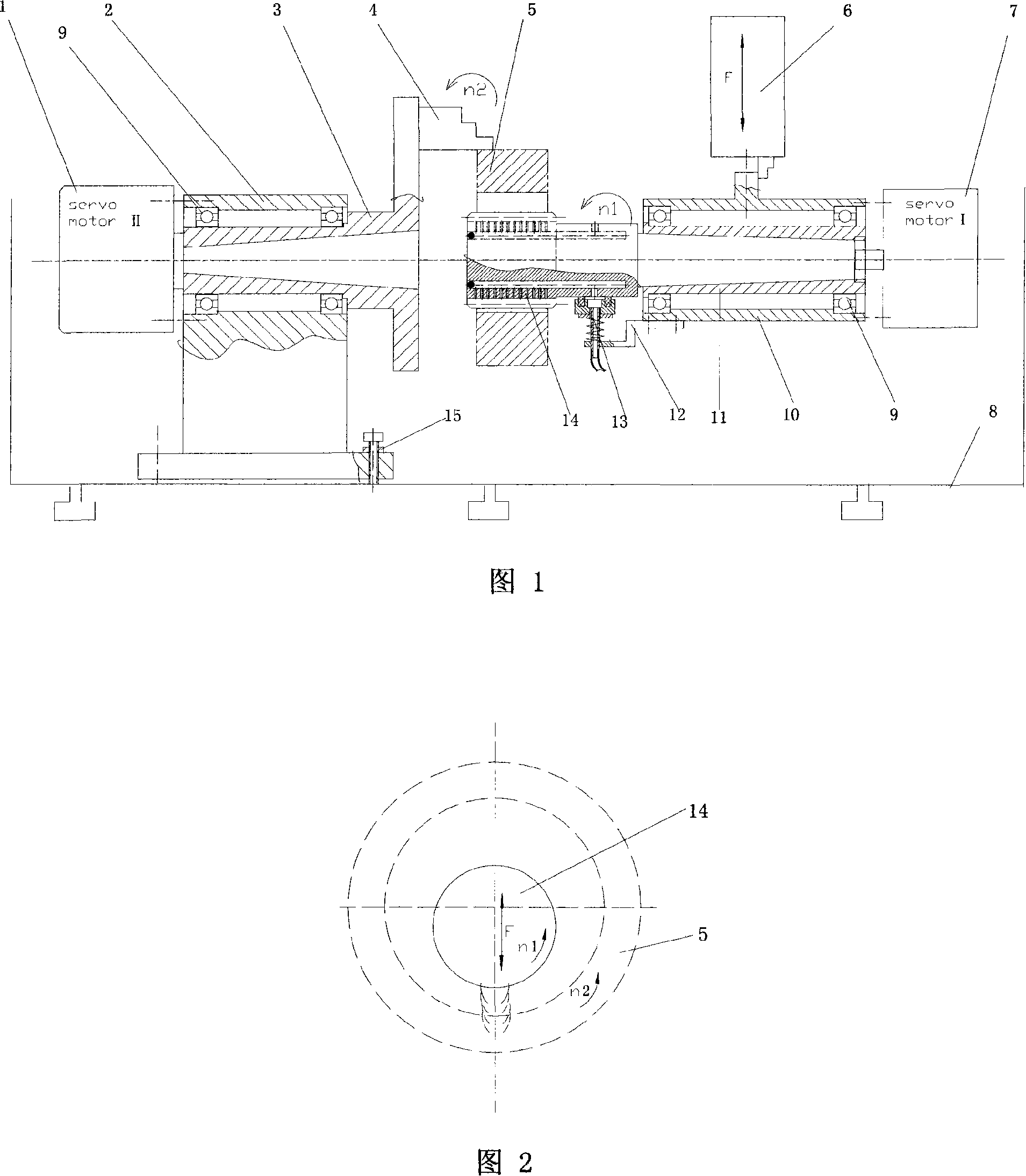

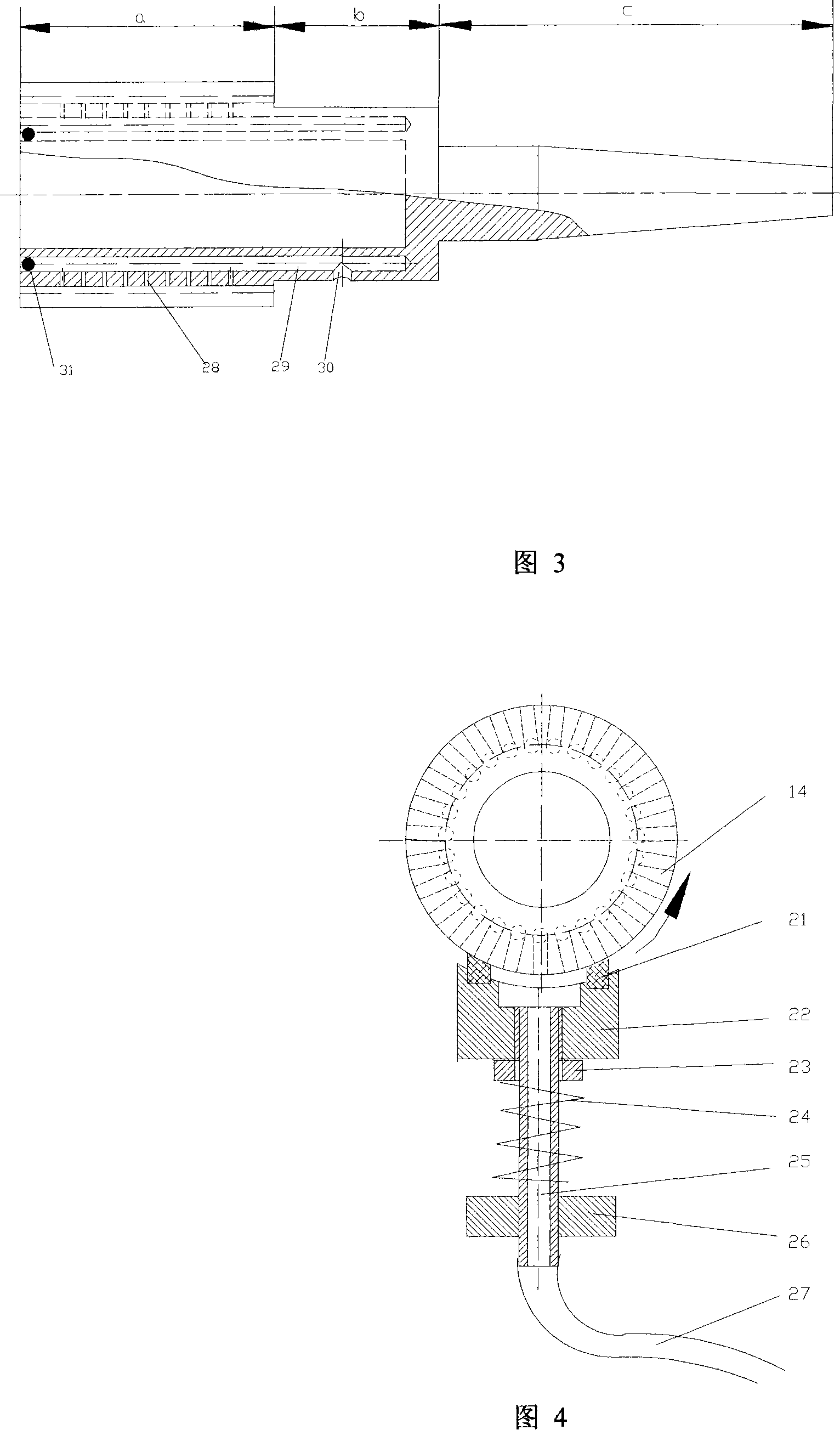

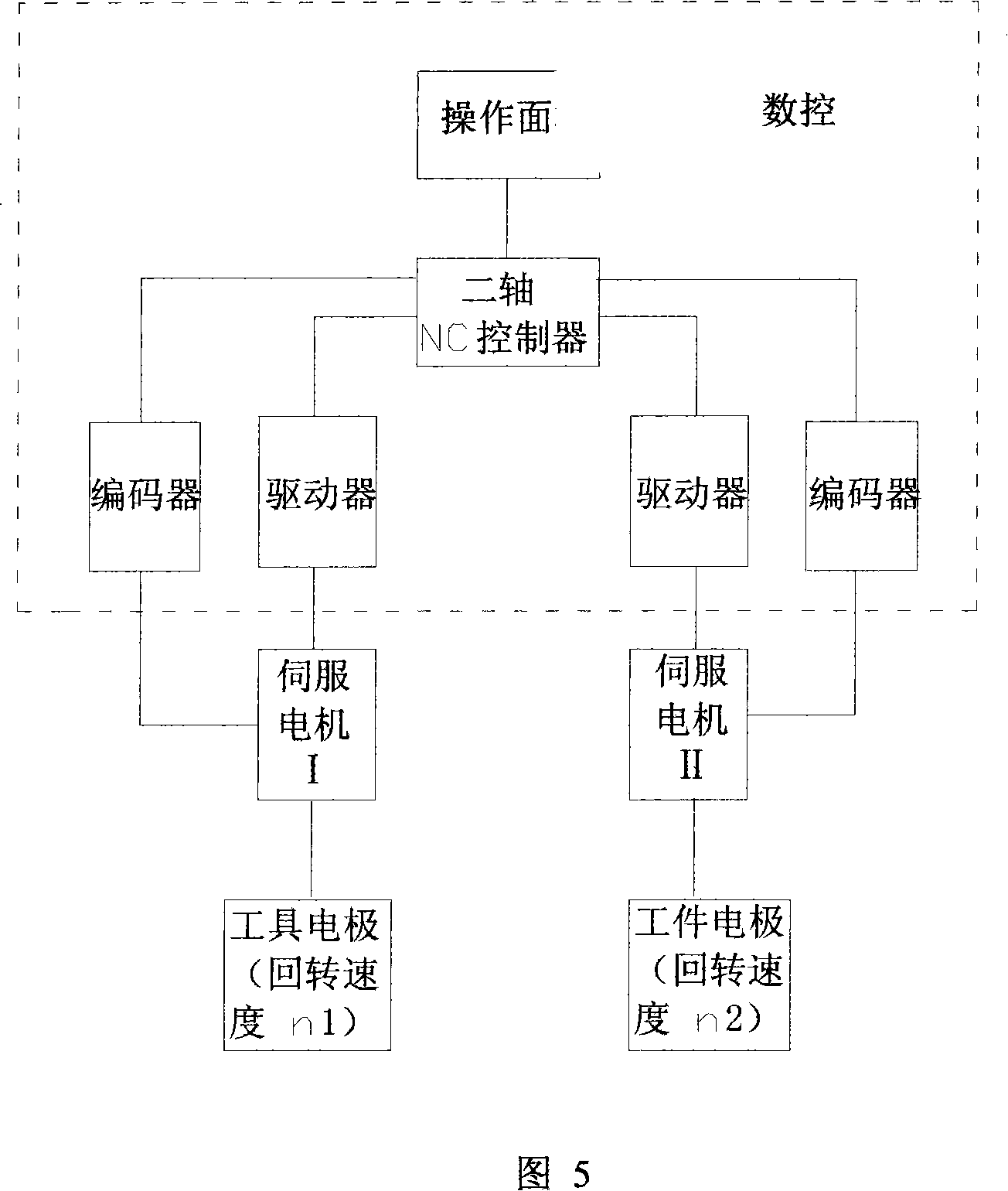

[0040] As shown in Figure 1, a large-depth-to-diameter ratio tooth-shaped female die numerical control EDM device adopts a horizontal layout as a whole, including a two-axis numerical control device, servo motor I7, servo motor II1, tool electrode 14, and three jaws. Fixture 4, workpiece rotary inner sleeve 3, local directional liquid supply introduction device 13 and tool electrode clamping shell 10, the two-axis numerical control device includes an operation panel, a two-axis NC controller, two drivers and two encoders, the two The axis numerical control device is connected with the servo motor I7 and the servo motor II1 respectively, and regulates the rotation speed (n1 and n2) of the two servo motors respectively. The seat 2 is fixed by the magnetic force of the general magnetic worktable of the EDM machine tool; the main shaft of the servo motor II1 is fixed and directly connected with the workpiece rotary inner sleeve 3, and the workpiece rotary inner sleeve 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com