High-efficiency vertically-arranged milling cutterhead and special blades

A milling and insert technology, which is applied in the field of high-efficiency vertical milling cutters and special inserts, can solve the problems of reduced service life of the insert, large cutting vibration, and high cutting speed, so as to improve the service life, reduce the clamping error, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

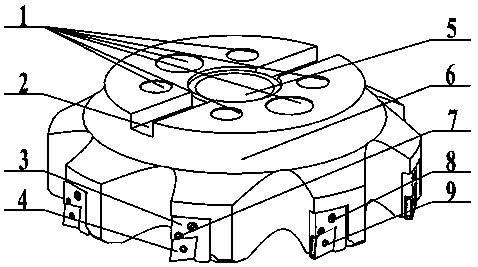

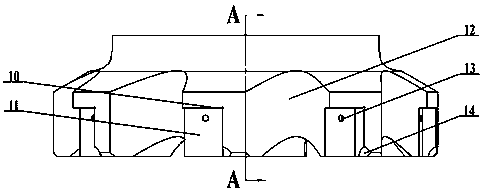

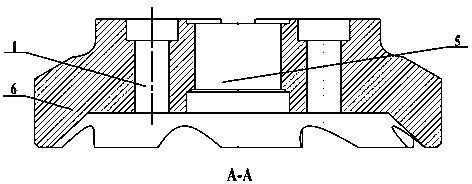

[0027] 1. Specific implementation mode one: combining figure 1 , figure 2 , image 3 As shown, the present invention is a high-efficiency vertical milling cutter head and a special blade. The center of the top of the cutter head (6) is provided with a main fastening bolt hole (5) and a keyway (2). The disc (6) is fixedly installed on the power shaft; the secondary mounting hole group (1) is provided around the main fastening bolt hole (5), so that the cutter head can be better connected and fixed with the power shaft; it can avoid the cutting vibration caused by the cutting tool The disk (6) is loosely connected with the power rotating shaft, thereby improving the tool life.

[0028] 2. Specific implementation mode two: combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a plurality of grooves (11) are arranged on the outer periphery of the cutterhead (6) in this embodiment, and locking screw holes (13) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com