Bridge lowering and dismantling device based on movable supporting and bridge lowering and dismantling construction method

A mobile support and construction method technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of endangering the health of surrounding residents, long construction time, waste of resources, etc., and achieve the reduction of close-range manual operations and high-altitude operations, construction Effects of improving safety and reducing work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

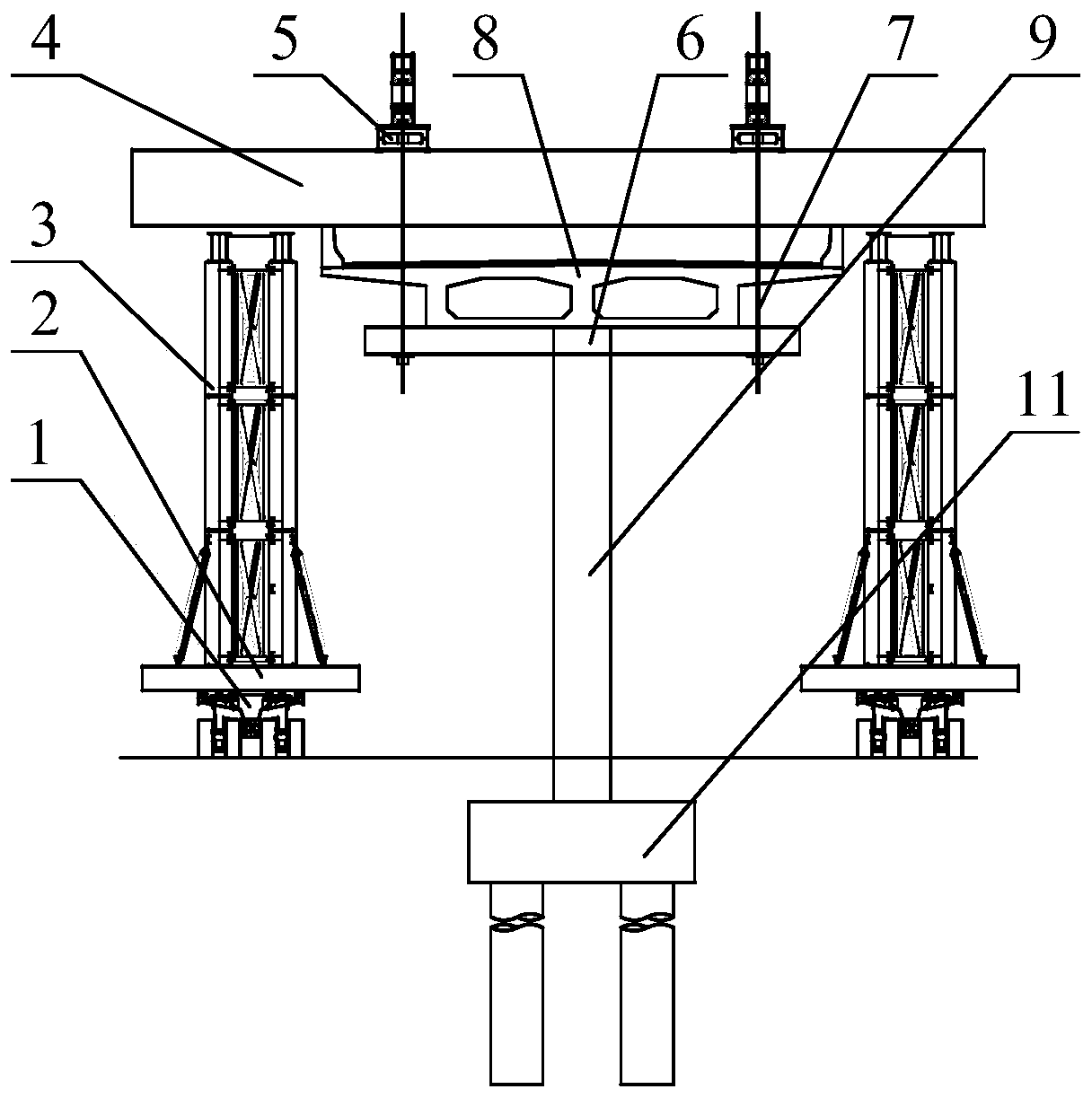

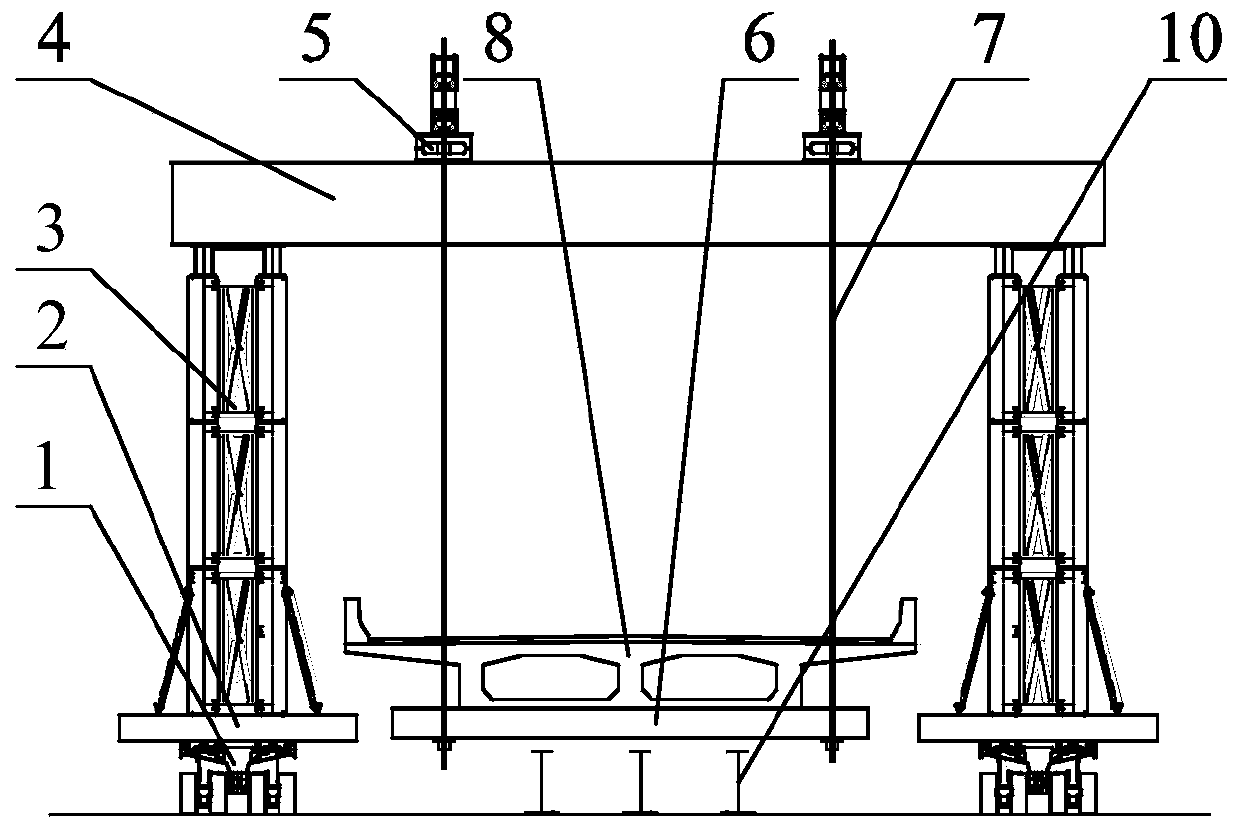

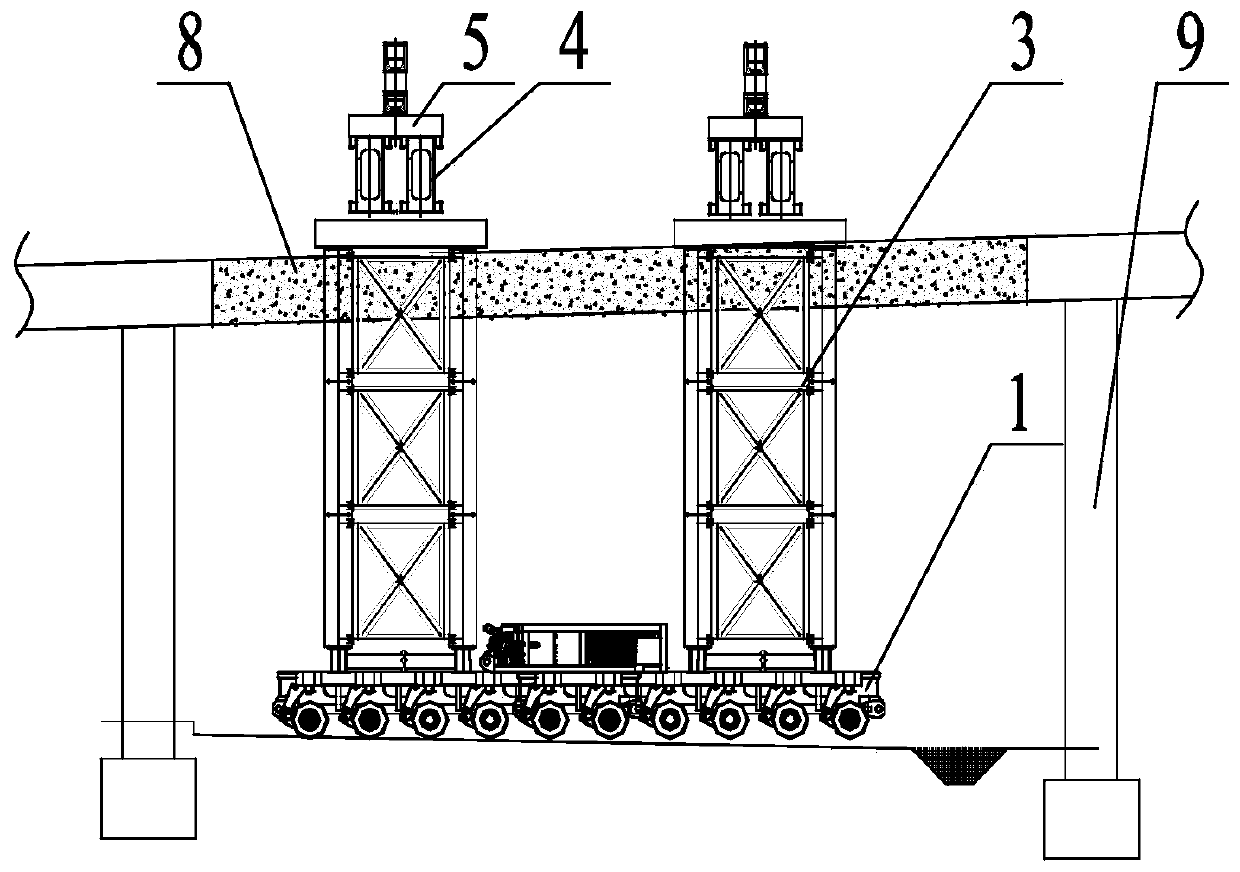

[0037] Such as figure 1As shown, a bridge lowering and dismantling device based on mobile support designed by the present invention includes a hoisting and lifting mechanism 5, two sets of spliced support frames 3 and two connecting support beams 4. The hoisting lifting mechanism 5 is installed on the connecting support beam 4 for hoisting the beam body 8 of the bridge. The two groups of spliced support frames 3 are symmetrically arranged below the two ends of the connecting support beam 4 for carrying the connecting support beam 4 . The two groups of spliced support frames 3 are detachably and fixedly connected to both ends of the support beam 4 . The bridge lowering and dismantling device also includes a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com