Multi-station multi-angle electrosparking device and method

A processing device and EDM technology, applied in the direction of electric processing equipment, accessory devices, metal processing equipment, etc., can solve the problems of inability to realize multi-angle processing of workpieces, limit the processing area of the workpiece surface, etc., achieve simple and reliable structure, and save processing Timing, ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

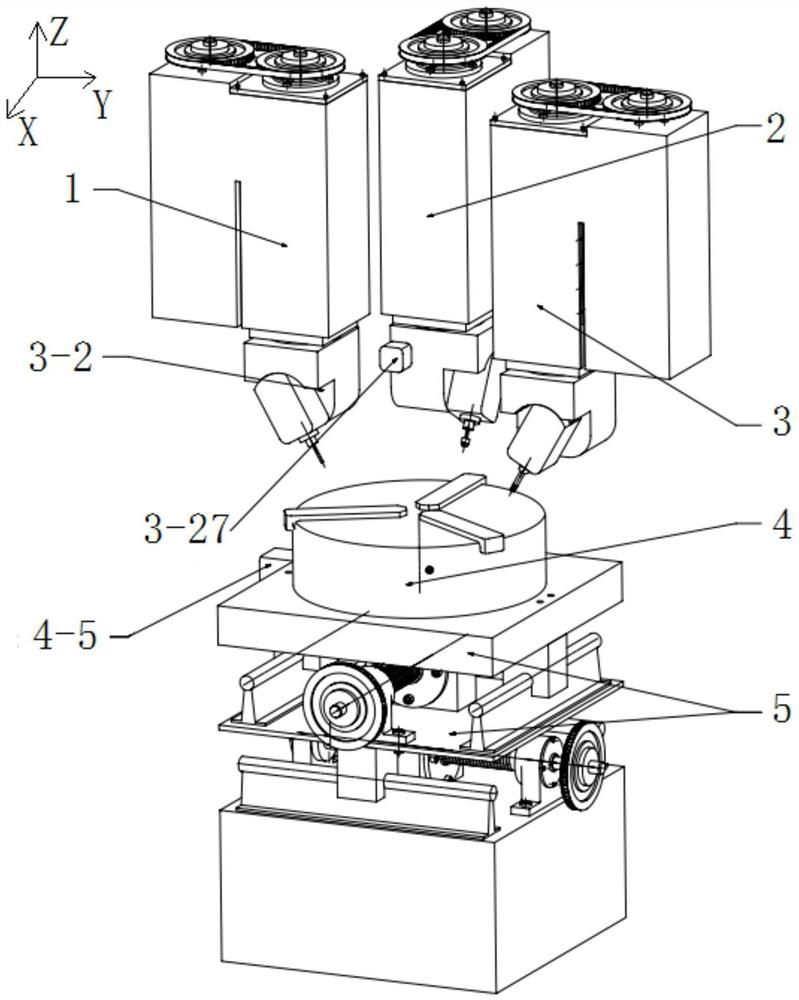

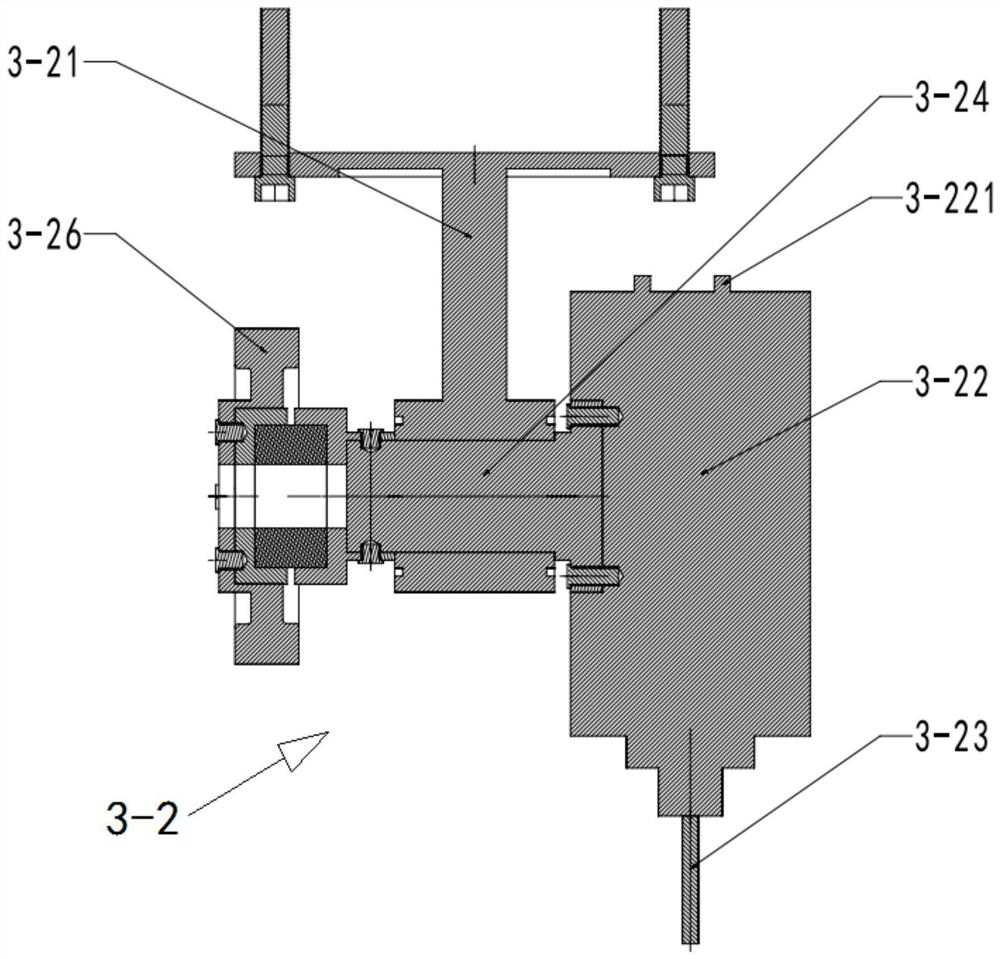

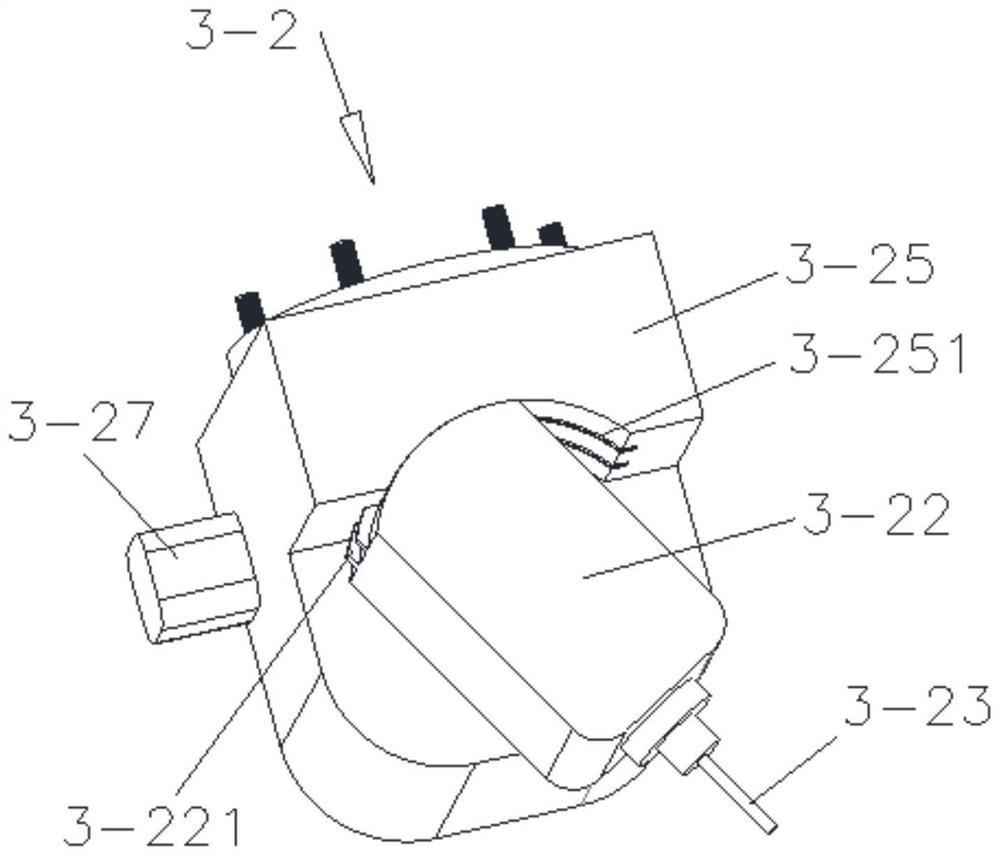

[0035] like Figure 1-8As shown, a multi-station and multi-angle electric discharge machining device establishes a spatial coordinate system with mutually perpendicular X-axis, Y-axis and Z-axis, wherein the Z-axis faces the vertical direction; the electric discharge machining device includes a first spindle Mechanism 1, second spindle mechanism 2, third spindle mechanism 3, rotary table 4 and slide table mechanism 5; the first spindle mechanism 1, second spindle mechanism 2 and third spindle mechanism 3 have the same structure, all including Spindle assembly 3-1 and spindle offset assembly 3-2, such as figure 1 , figure 2 and image 3 As shown, the spindle bias assembly 3-2 includes a rotary support base 3-21, an electrode chuck 3-22 and a tool electrode 3-23, and the tool electrode 3-23 is fixedly arranged on the electrode chuck 3-22 , the electrode chuck 3-22 is rotated on the rotary support base 3-21 through the rotation shaft 3-24, and the rotation axis of the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com