Numerically controlled lathe clamp assembly for machining rotary pipe joints with balls and machining method thereof

A technology of rotating pipe joints and CNC lathes, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve problems such as difficulty in guaranteeing, poor processing accuracy, and poor coaxiality of plane parallelism at both ends of the spherical part. Achieve the effect of reducing clamping error and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

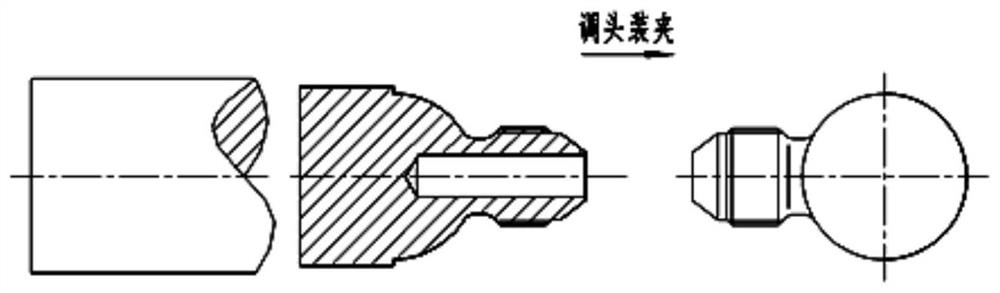

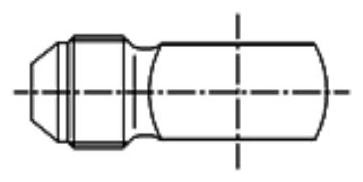

[0035] Attached below Figure 4-7 The invention will be further described with specific embodiments to help understand the content of the present invention.

[0036] The present invention provides a fixture combination, which is used for clamping and fixing the workpiece (semi-finished rotary pipe joint) when machining the two parallel end faces of the spherical part of the rotary pipe joint and the step holes at both ends, including the first working step fixture 1 And the second work step fixture 2. Through the fixture 1 of the first working step and the fixture 2 of the second working step, the process of milling the plane, turning the inner hole of the step and boring the inner cavity is combined with the CNC lathe to reduce the clamping error caused by the conversion of the clamping reference, and the milling machine is replaced by the CNC lathe Face milling also reduces machining time and reduces the variety of machine tools used.

[0037] Such as Figure 4 and Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com