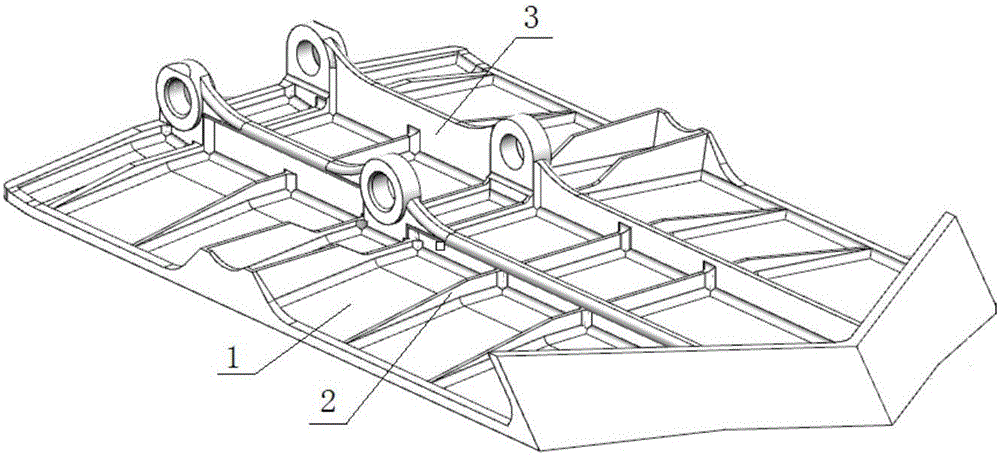

Drilling and milling device for adjustment sheet type part

A technology for adjusting pieces and parts, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as difficult to ensure the processing size, hinder the opening of the adjusting pieces, long processing cycle, etc., to achieve convenient processing and use, and shorten the processing cycle , Reduce the effect of clamping error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

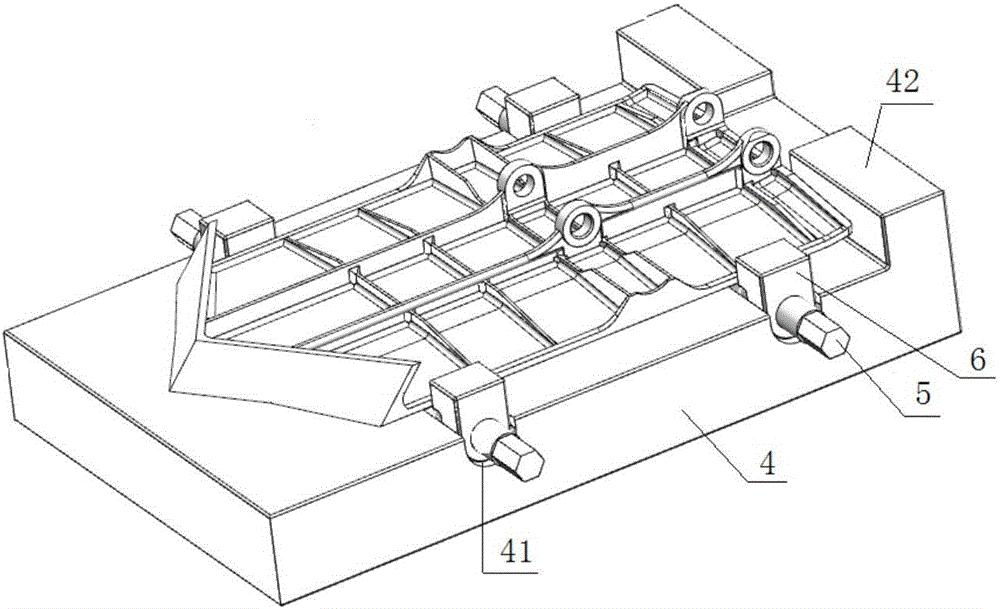

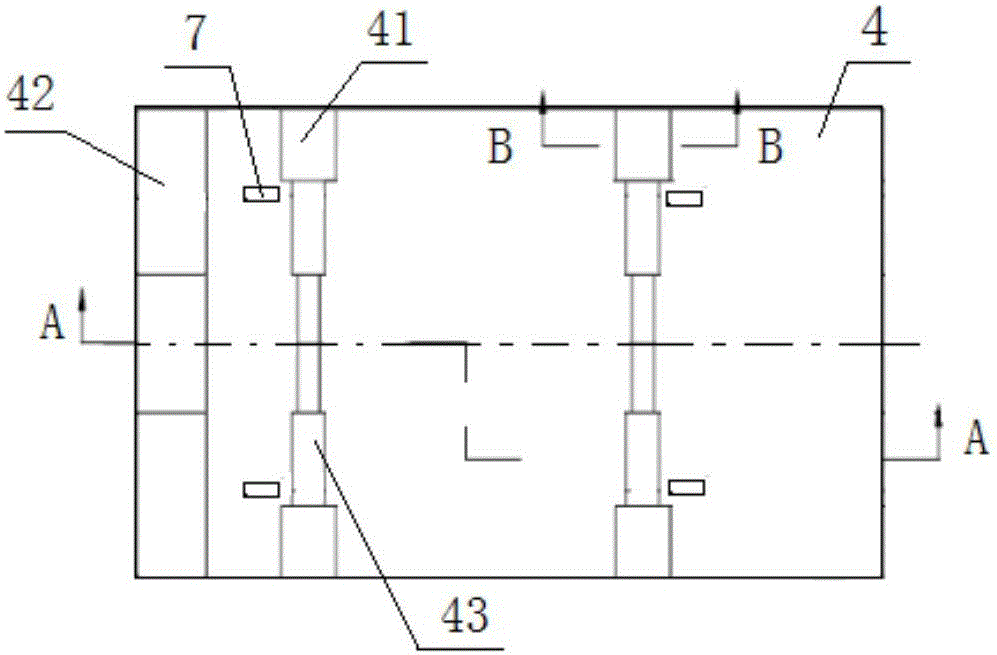

[0026] Such as figure 2 As shown, a drilling and milling device for regulating piece parts according to the present invention includes a fixture main body 4, a centering screw 5 and a centering pressure plate 6. The fixture main body 4 is provided with a screw mounting groove 43, and the fixture main body 4 is located on the The two ends of the screw installation groove 43 are provided with a briquetting installation groove 41, the centering screw 5 is installed in the screw installation groove 43, and the centering pressure plate 6 is respectively set on the two ends of the centering screw 5 and placed in the briquetting installation groove 41, the fixture main body 4 is also provided with a support block 7 outside the screw mounting groove 43. The fixture adopts end face positioning and four-point support, and realizes automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com