Lubricating and sealing method of hexagonal bionic texture of reciprocating column casing structure

A reciprocating and hexagonal technology, which is applied in the field of bionic hexagonal texture structure, can solve the problems of incomplete coverage of oil, dry friction, and reduced sealing, so as to shorten the production cycle, reduce friction, and improve The effect of pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

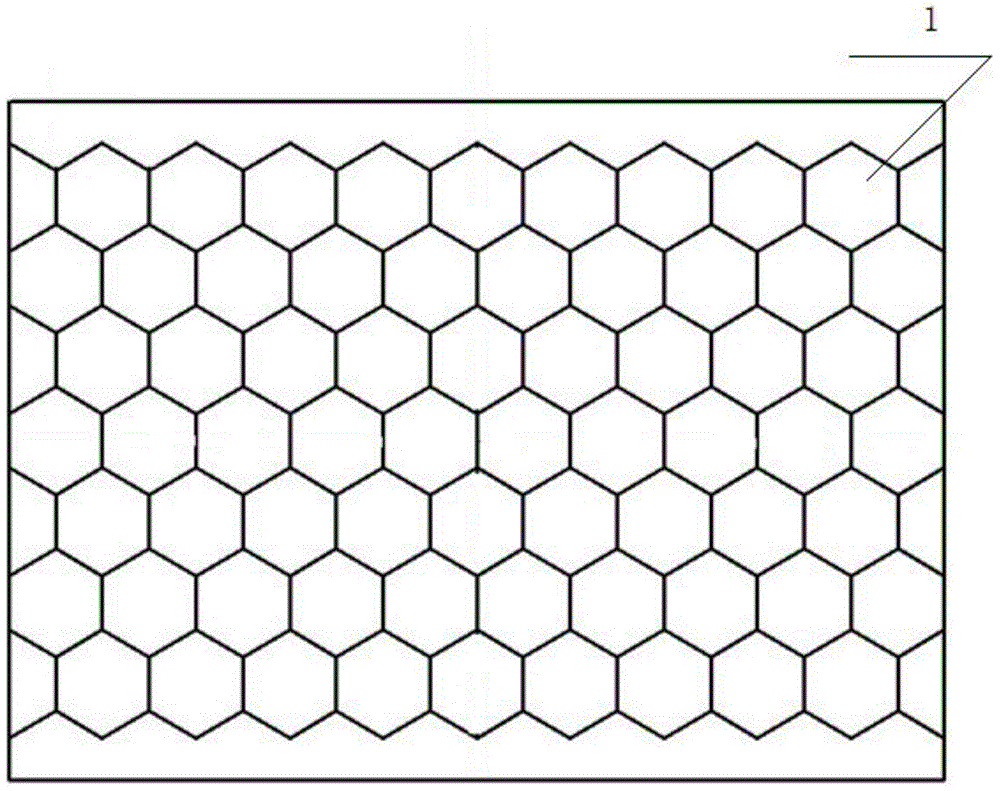

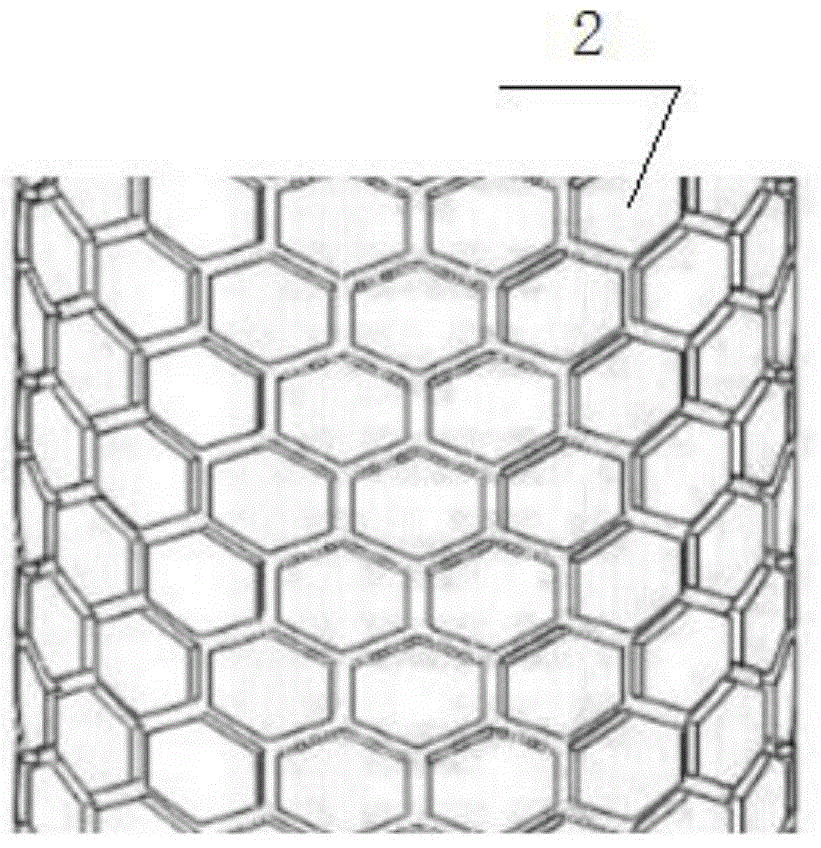

[0027] No. 45 steel rod is used to process the plunger parts with bionic hexagonal texture surface. The design requirements are: the groove width of hexagonal texture structure is 1mm, the depth is 0.5mm, and the final processing length is 100mm.

[0028] Include the following steps

[0029] Step 1. Shape processing

[0030] Such as figure 1 As shown, the biomimetic hexagonal textured surface 1 is produced and processed. Take the rough bar of No. 45 steel to process the outer surface of the plunger part, use the lathe to process the rough bar of No. 45 steel, and clamp one end of the rough bar on the three-jaw chuck of the lathe, and the clamping length is 50mm , start the lathe, and turn the outer surface of the plunger part on the blank bar.

[0031] Step 2. Surface machining

[0032] Use the CNC milling machine to machine the surface of the No. 45 steel plunger parts after the shape processing, and through the control of the tool walking route programming module of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com