Group machining tooling and process for steam turbine blade multi-pass arc surface

A steam turbine blade and group processing technology, which is applied to metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of easy wear of fixtures, poor roughness, and large vibration, and achieve low tool cost and good consistency , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

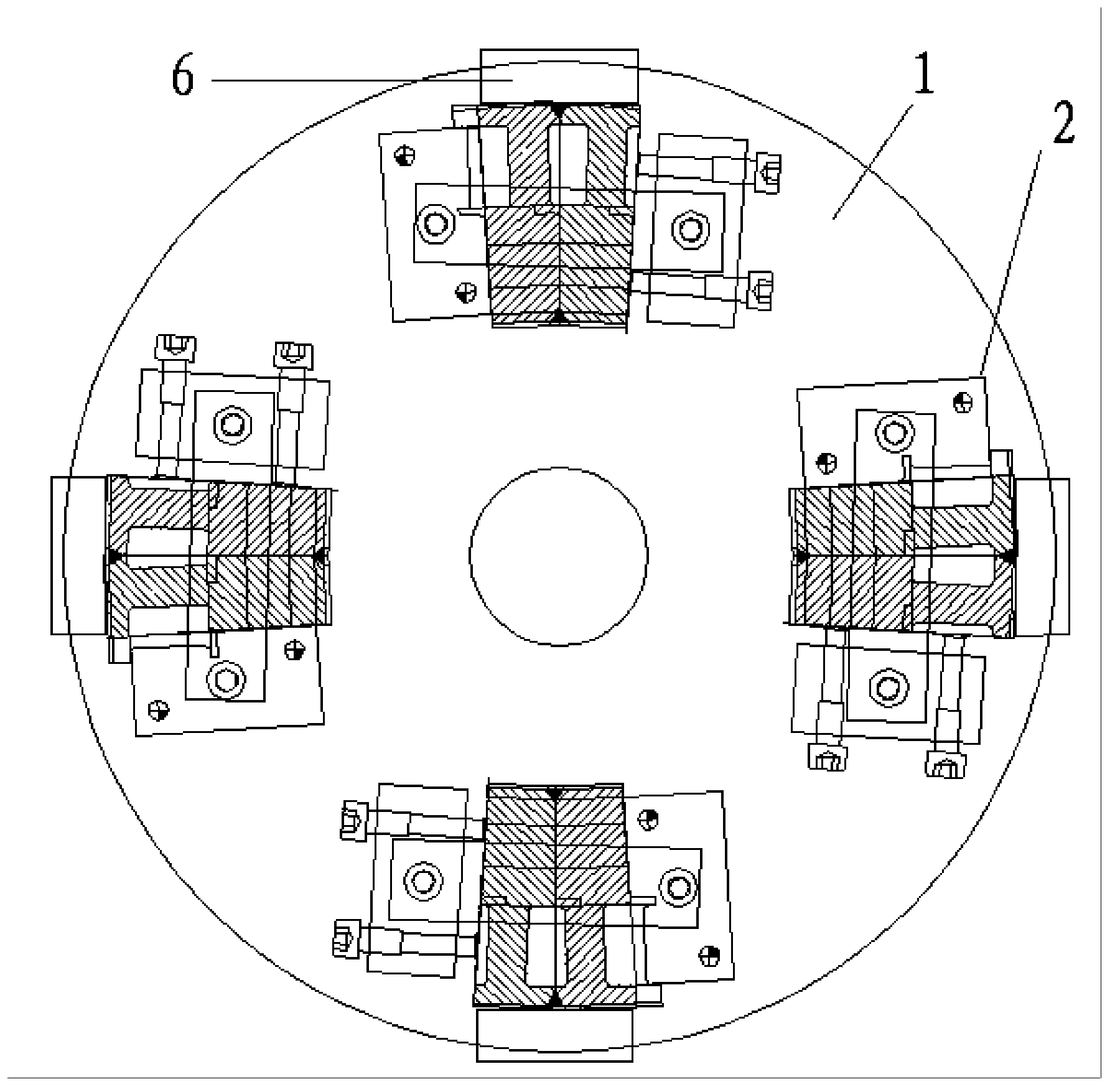

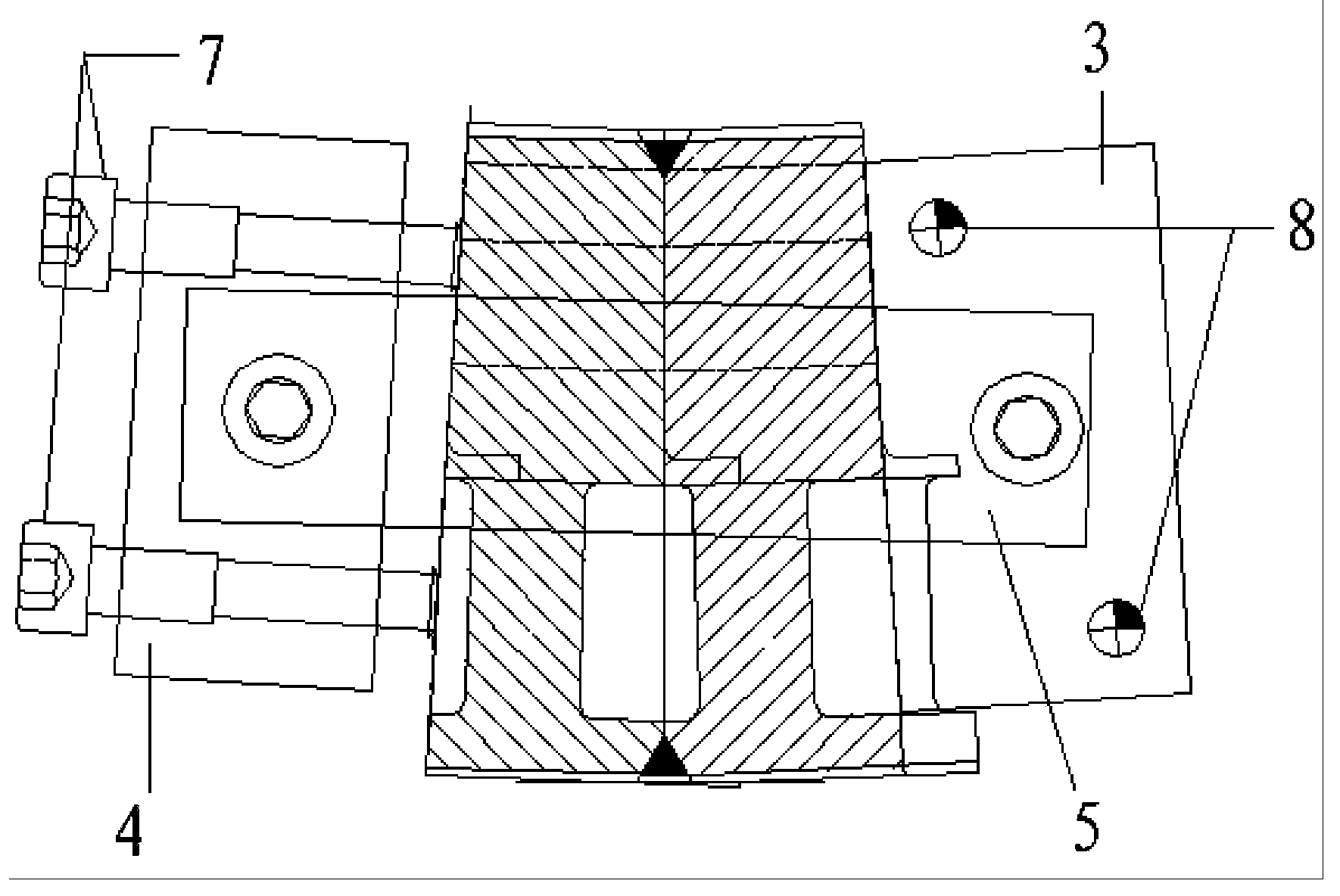

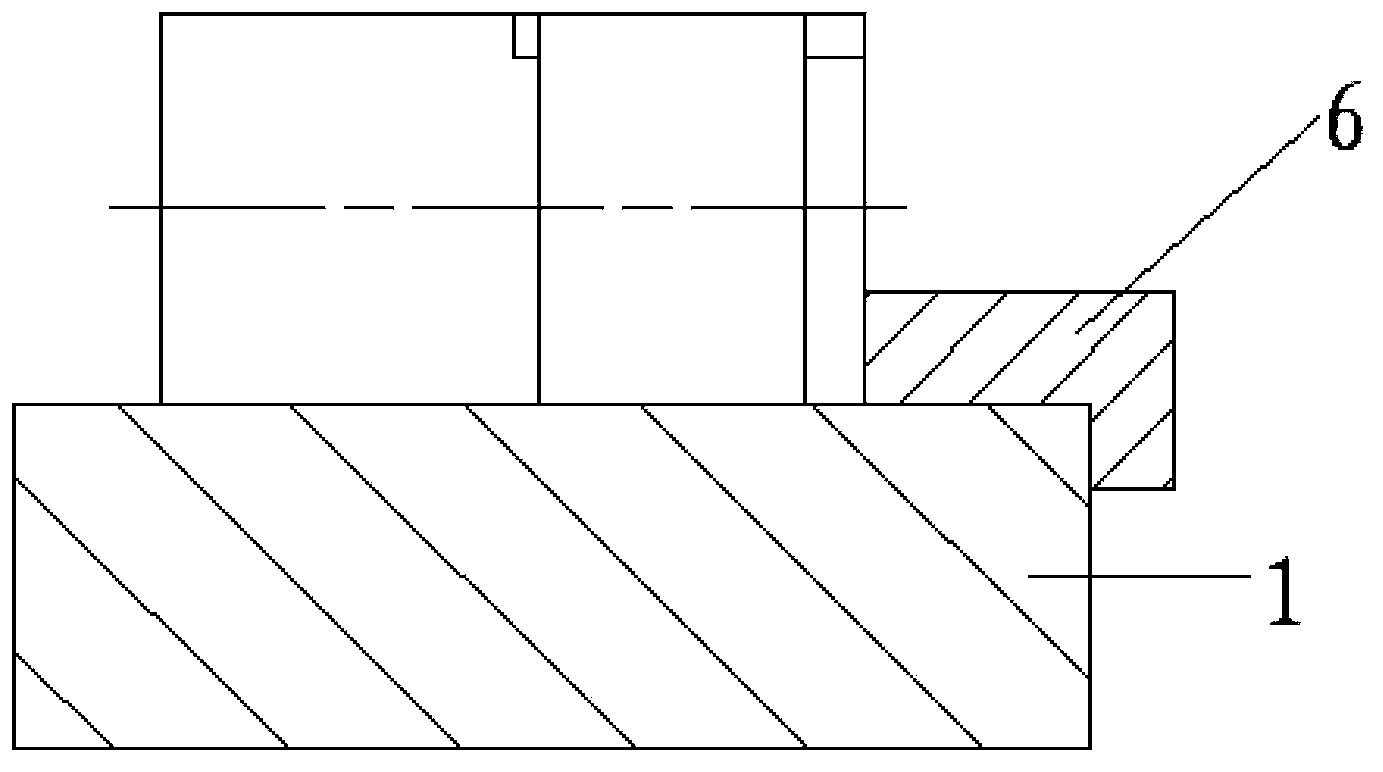

[0031] refer to Figure 1 to Figure 3 As shown, the multi-arc surface of steam turbine blades is a group processing tooling, and the circular arc processing installation disc 1 is set on the rotary table of the vertical lathe, and the surface is provided with several blade clamping parts 2, and several blade clamping parts 2 It is arranged on the same circumference and is concentric with the arc processing and installation disk 1 and the turntable; a radial positioning block 6 is arranged between the blade clamping part 2 and the outer circle side of the arc processing and installation disk 1; the blade clamp The mounting part 2 is composed of a positioning block 3, a pressing block 5 and a fixed block 4 connected in sequence, and the pressing block 5 is arranged on the top of the positioning block 3 and the fixing block 4; the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com