A High Power Density Reluctance Motor

A high power density, reluctance motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, winding conductor shape/style/structure, etc., can solve the problem of low power density, system noise reduction, etc. problem, to achieve the effect of increasing power density, reducing volume and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

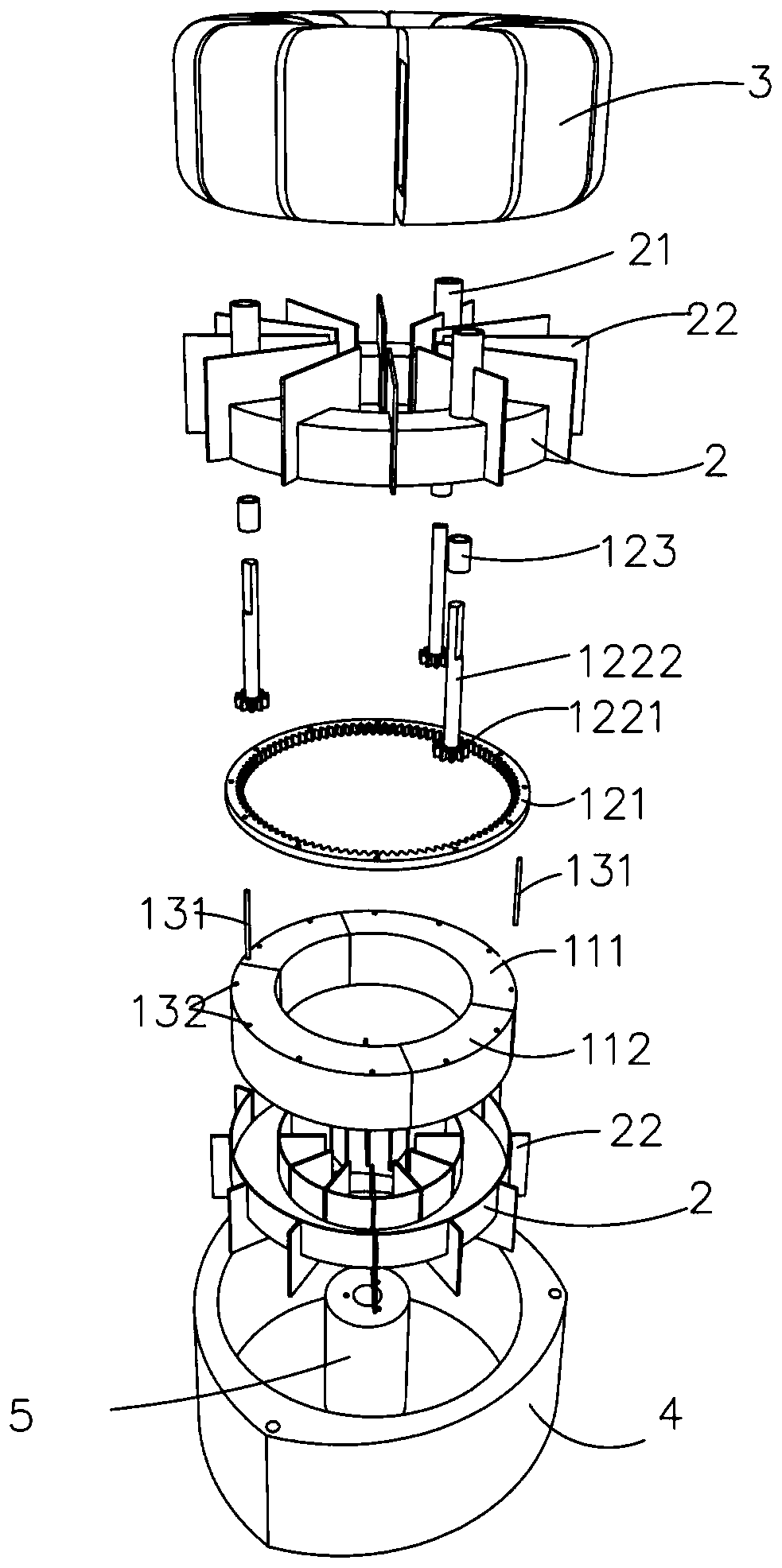

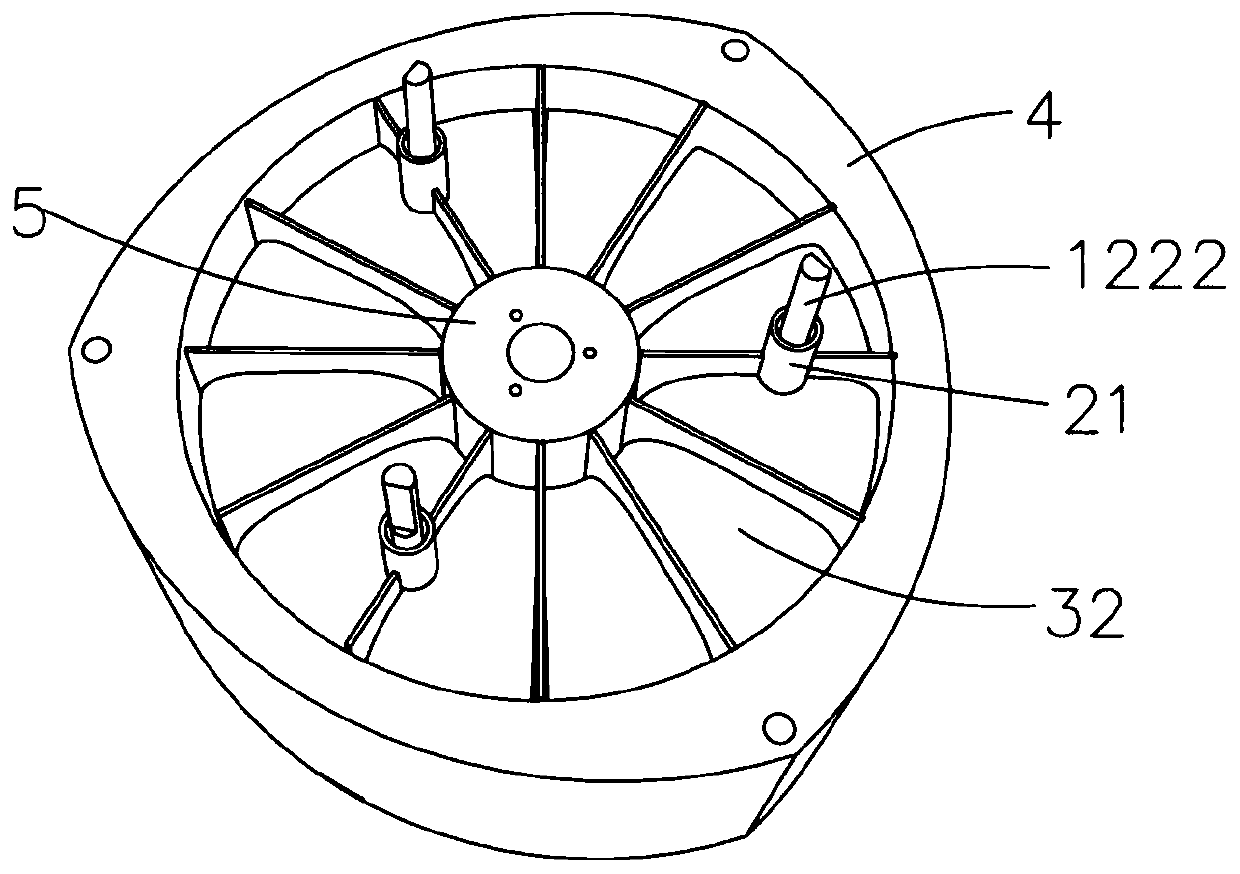

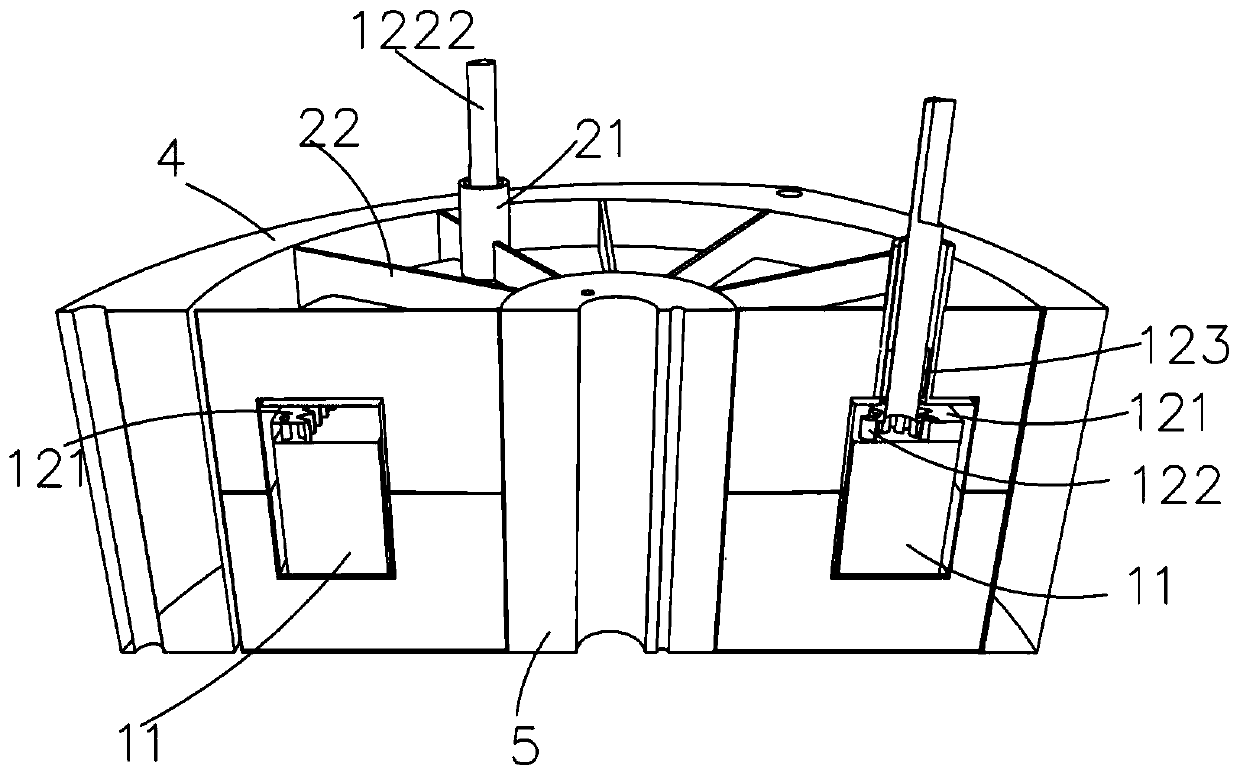

[0032] see Figure 1 to Figure 11 As shown, in the following, the reluctance motor according to the embodiments of the present invention will be described in detail with reference to the accompanying drawings. In addition, the components described in the following embodiments can be replaced by components that can be easily imagined by those skilled in the art, or Substantially the same components as those in the following embodiments may be substituted.

[0033] mainly as Figure 1 to Figure 5 As shown, the high power density reluctance motor of the present invention includes a rotor 1, a rotor casing 2 and a winding 3, the rotor 1 is arranged in the rotor casing 2, and the winding 3 includes a plurality of coils 32, and the coils 32 are all wound set on the rotor housing 2;

[0034] The rotor includes an annular rotor body 11 and a gear set 12; the rotor housing 2 is an annular structure of non-magnetic material; the rotor housing 2 can be composed of upper and lower parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com