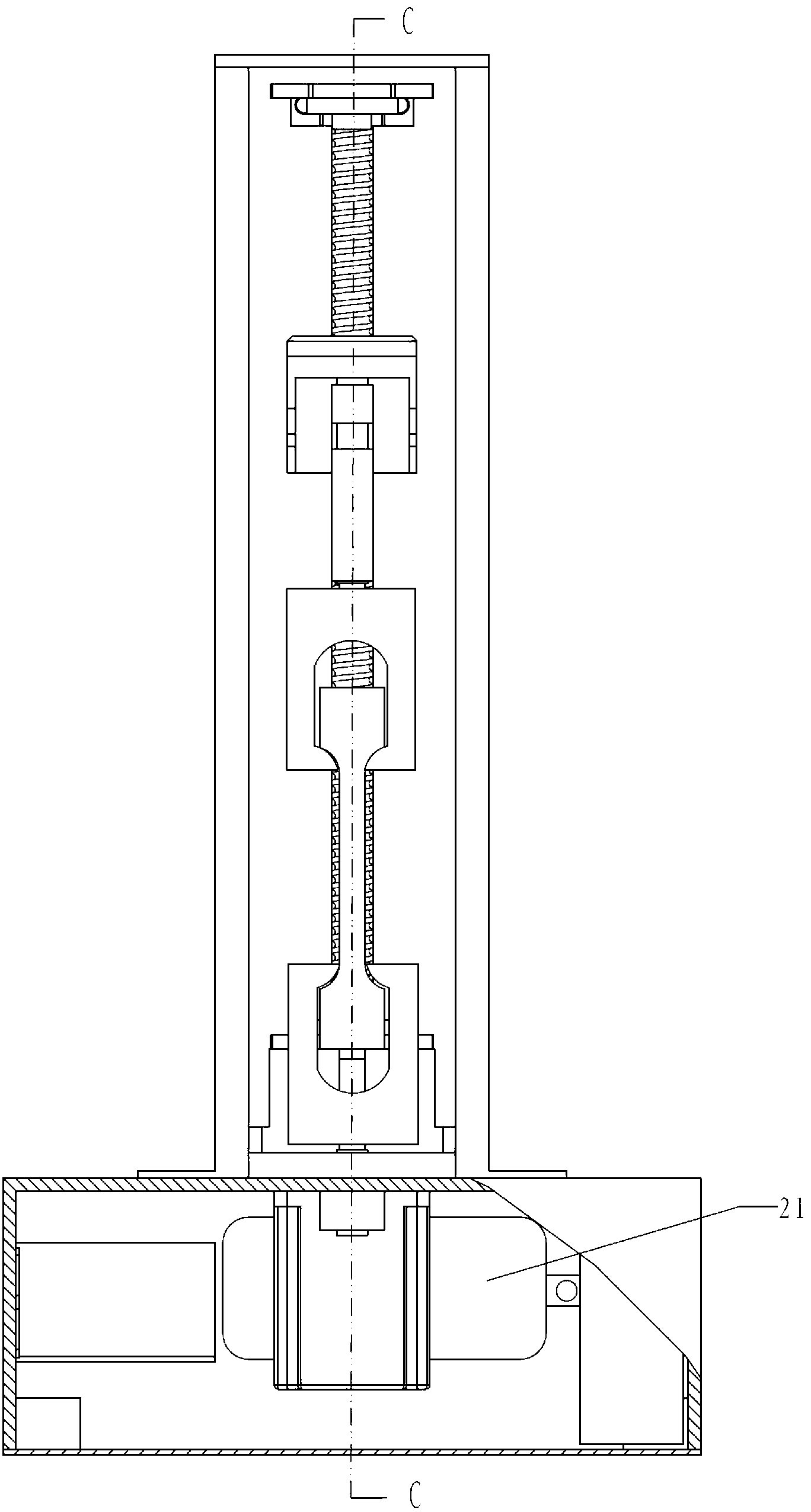

Macromolecular material tensile testing device

A polymer material and tensile test technology, which is applied in the field of polymer material tensile test equipment, can solve problems such as complex process, high equipment manufacturing cost, and large floor area of double-column structure, so as to improve test accuracy and reduce Small footprint, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

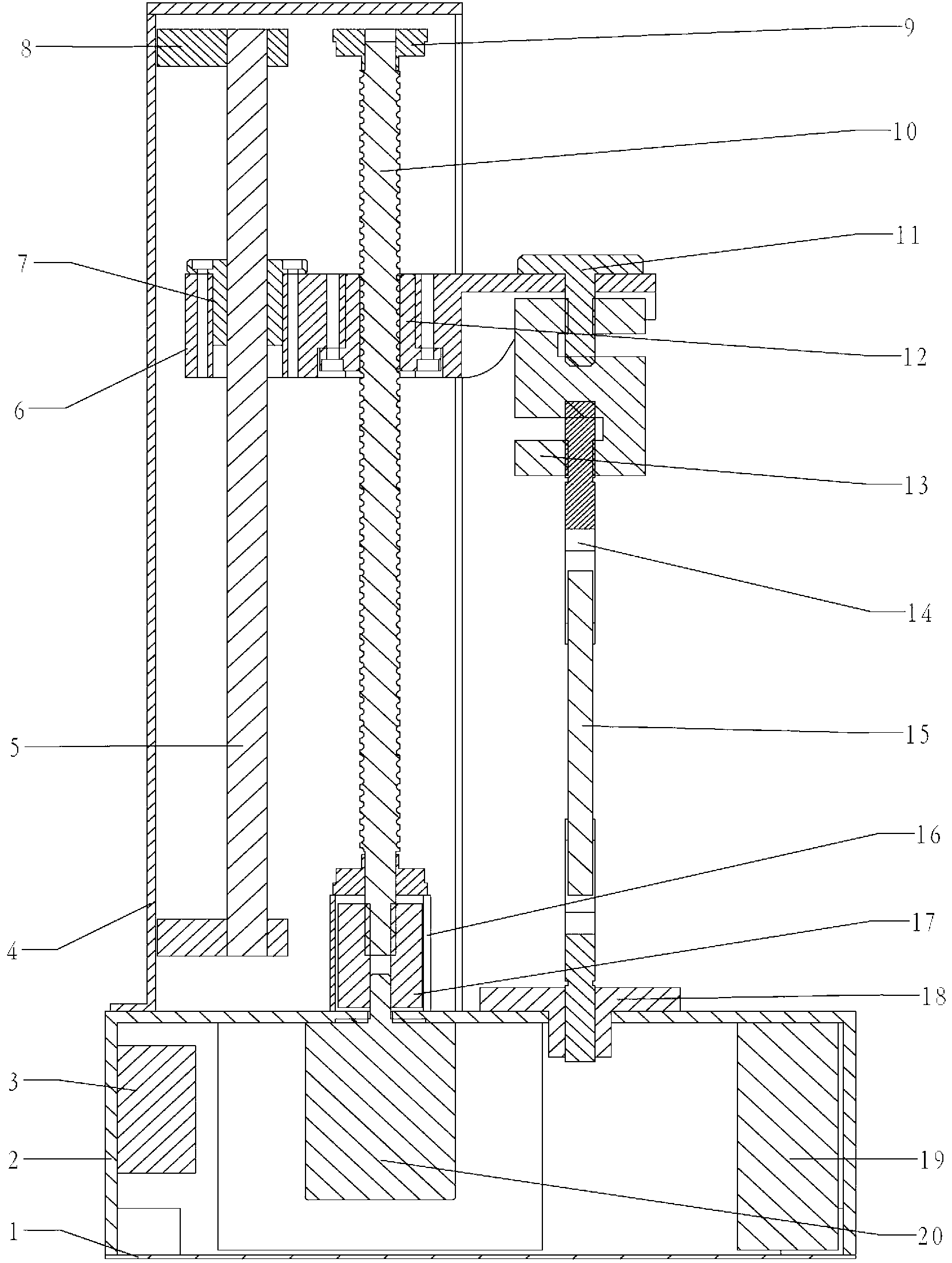

[0015] The design standard of the present invention is a loading speed of 850 mm / min, which can be selected in the range of 400 to 850 mm / min according to actual needs. Since the tensile deformation stress of the polymer material is small, the tensile rate of the system is also relatively slow. In this way, on the premise of ensuring the output torque, the reduction box can be omitted, the structure size can be reduced and the cost can be saved. Simultaneously, because the rotation of ball screw does not have self-locking function, and the self-locking function of the stepper motor (20) with encoder can make up for the deficiency of this respect, avoids the occurrence of rotation caused by motor stopping, guarantees The position accuracy of the present invention is improved.

[0016] The pressure sensor (13) that the present invention adopts is S-type weighing sensor, and this weighing pressure sensor selects SM6 type for use, and its measuring range is 50kg, and the output ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com