Drive motor and series-parallel type hybrid power systems

A technology for driving motors and shells, which is applied in the direction of hybrid vehicles, power devices, and air pressure power devices, etc. It can solve the problems of increased size and weight of the driving motor, restrictions on the installation and use of the driving motor, and achieve overall size and weight reduction. Improved range of use, size and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

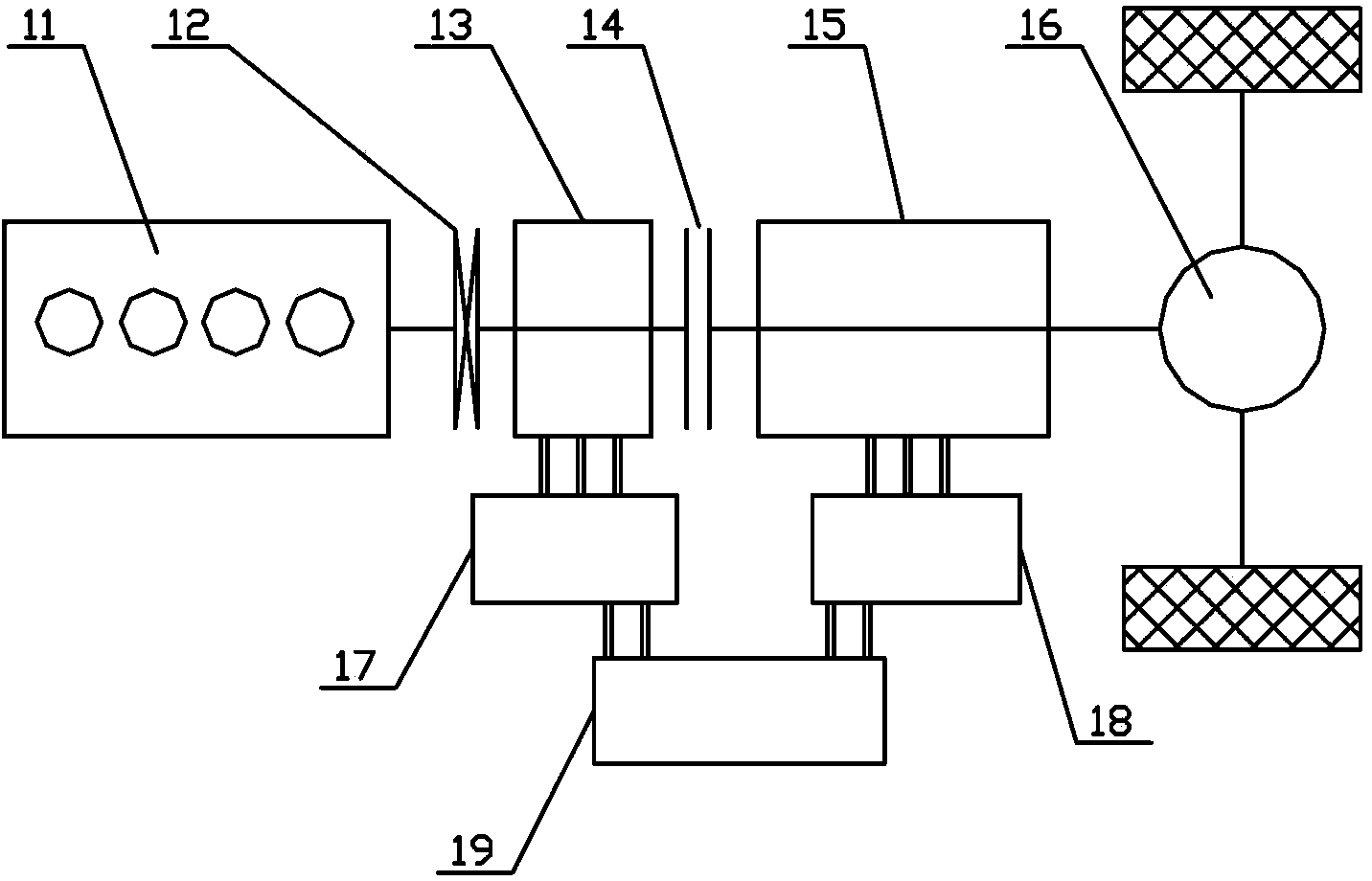

Embodiment 1

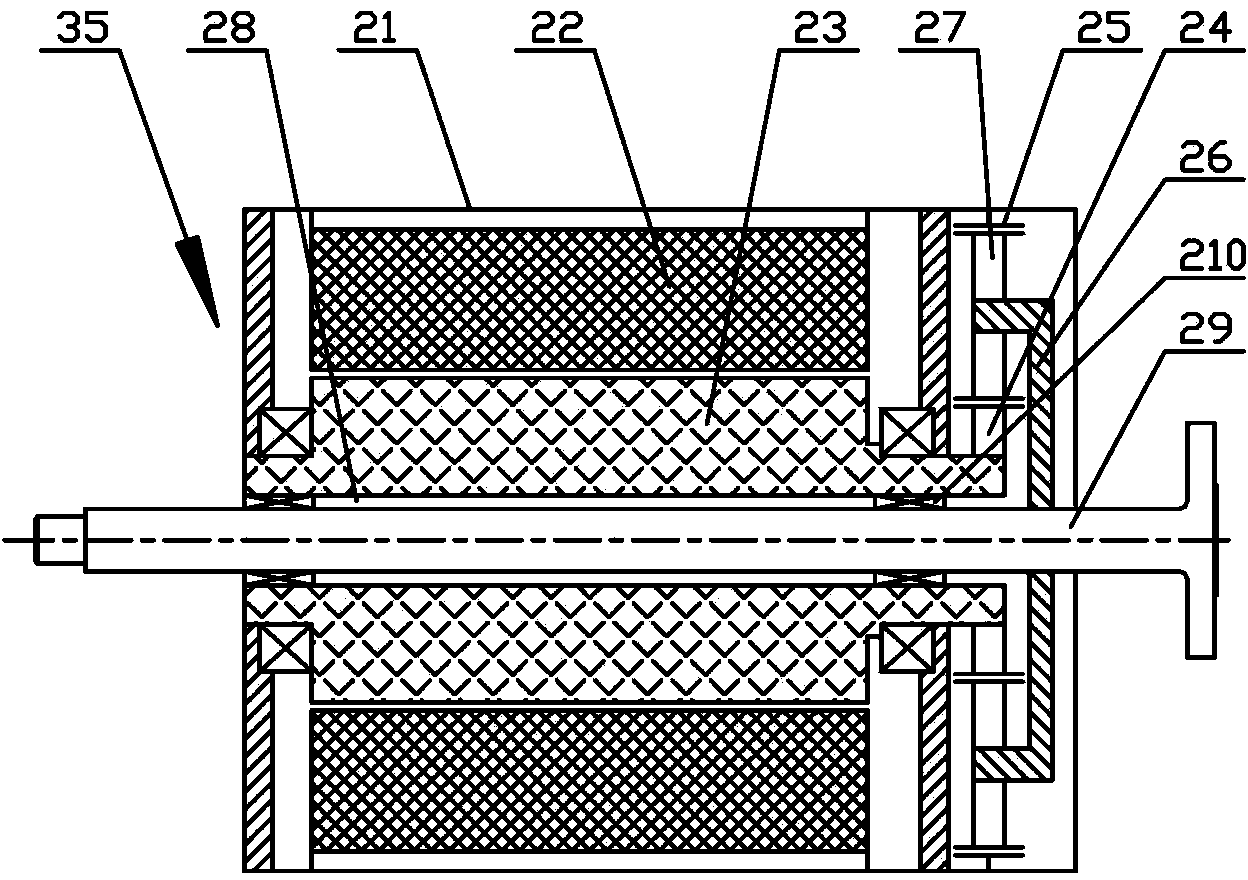

[0066] Such as figure 2 As shown, the drive motor provided in this embodiment includes a housing 21, a stator 22 and a rotor 23 placed in the housing 21; the output shaft of the rotor 23 is sleeved and fixed with a sun gear 24, and the inside of the housing 21 is fixed There is an inner ring gear 25, and both the sun gear 24 and the inner ring gear 25 mesh with the planetary gear 27 mounted on the planet carrier 26; wherein, the middle part of the rotor 23 is formed with a through hole 28 along the axial direction, and the through hole 28 is provided with a The rotating output connecting shaft 29; and the planet carrier 26 is fixedly installed on the output end of the output connecting shaft 29.

[0067] When in use, the drive motor 35 starts, the rotor 23 starts to rotate, and the output shaft of the rotor 23 drives the sun gear 24 to rotate; driven by the rotation of the sun gear 24, the planetary gear 27 starts to rotate in the planet carrier 26, and the planetary gear 27 ...

Embodiment 2

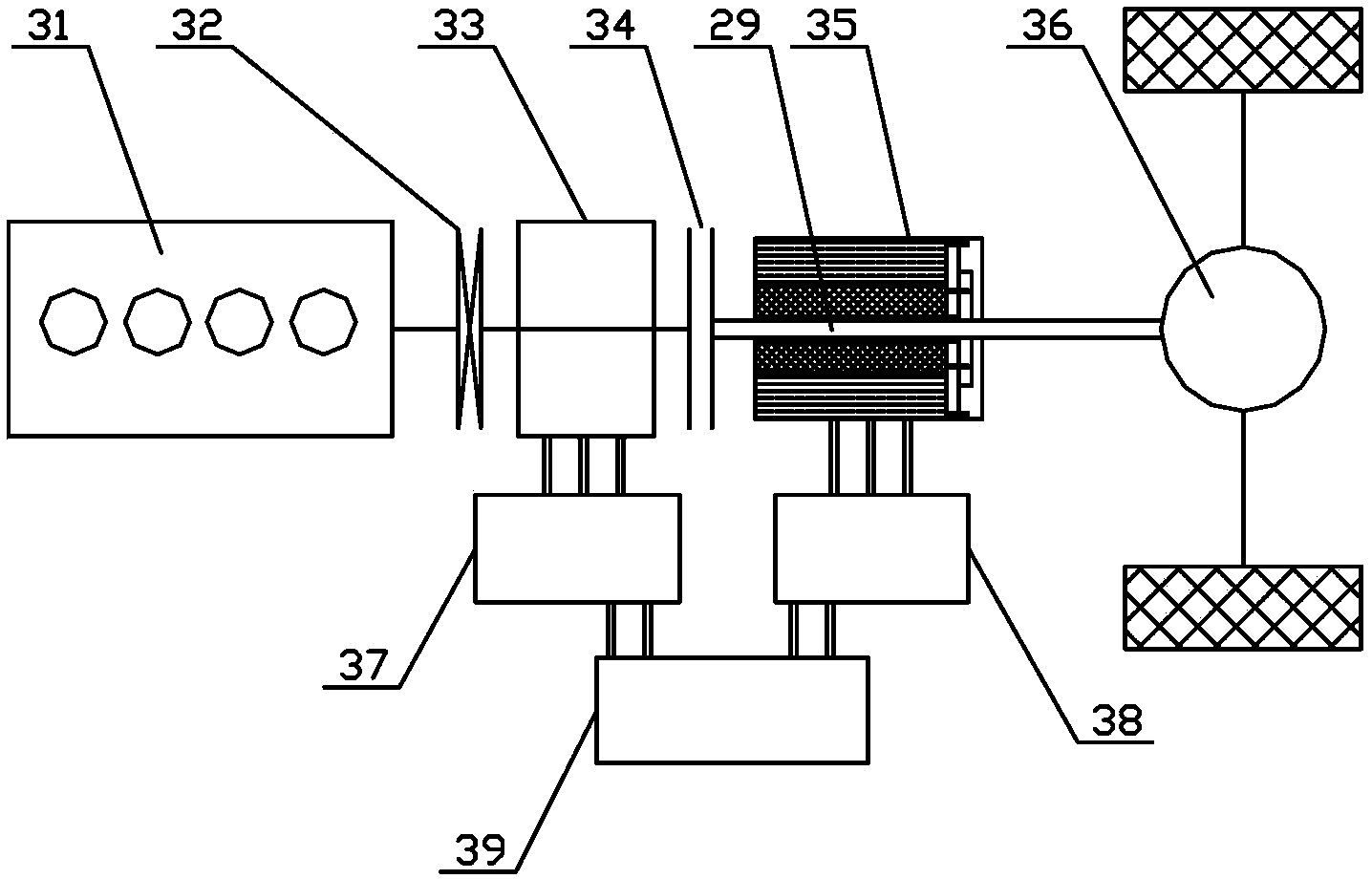

[0079] Such as image 3 As shown, the series hybrid system provided in this embodiment includes an engine 31 and a torsional damper 32 and a generator 33 arranged on the output shaft of the engine 31 in sequence, and the output shaft of the engine 31 and the clutch 34 The input end links to each other; the output end of the clutch 34 links to each other with the input end of the output connection shaft 29 in the drive motor 35 described in the above-mentioned embodiment one, and the output end of the output connection shaft 29 links to each other with the drive axle 36; the generator 33 passes through the first A motor controller 37 is connected with the energy storage device 39 , and the drive motor 35 is connected with the energy storage device 39 through the second motor controller 38 .

[0080] It should be noted that the engine 31, the torsional shock absorber 32 and the generator 33 are not necessarily connected sequentially through a main shaft, but can also be connecte...

Embodiment 3

[0089] Such as Figure 4 As shown, the series hybrid system provided in this embodiment includes an engine 31 and a clutch 34 whose input end is connected to the output shaft of the engine 31. The output end of the clutch 34 is connected to the drive motor 35 described in the first embodiment above. The input end of the output connecting shaft 29 in is connected, and the output end of the output connecting shaft 29 is connected with the transaxle 36; the output shaft of the engine 31 is connected with the generator 33 through the transmission device 310; the generator 33 is connected with the generator 37 through the first motor controller 37 The energy storage device 39 is connected, and the driving motor 35 is connected with the energy storage device 39 through the second motor controller 38 .

[0090] The overall structure of the hybrid hybrid system provided in this embodiment is similar to the hybrid hybrid system provided in Embodiment 2, and its specific working process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com