Method for controlling frequency converter to start plurality of large motors by using PLC

A technology of frequency converter and large motor, which is applied in the field of motor control, can solve the problems of accelerated motor aging, grid voltage reduction, shortened service life, etc., and achieve the effects of guaranteed output torque, small starting current, and smooth acceleration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

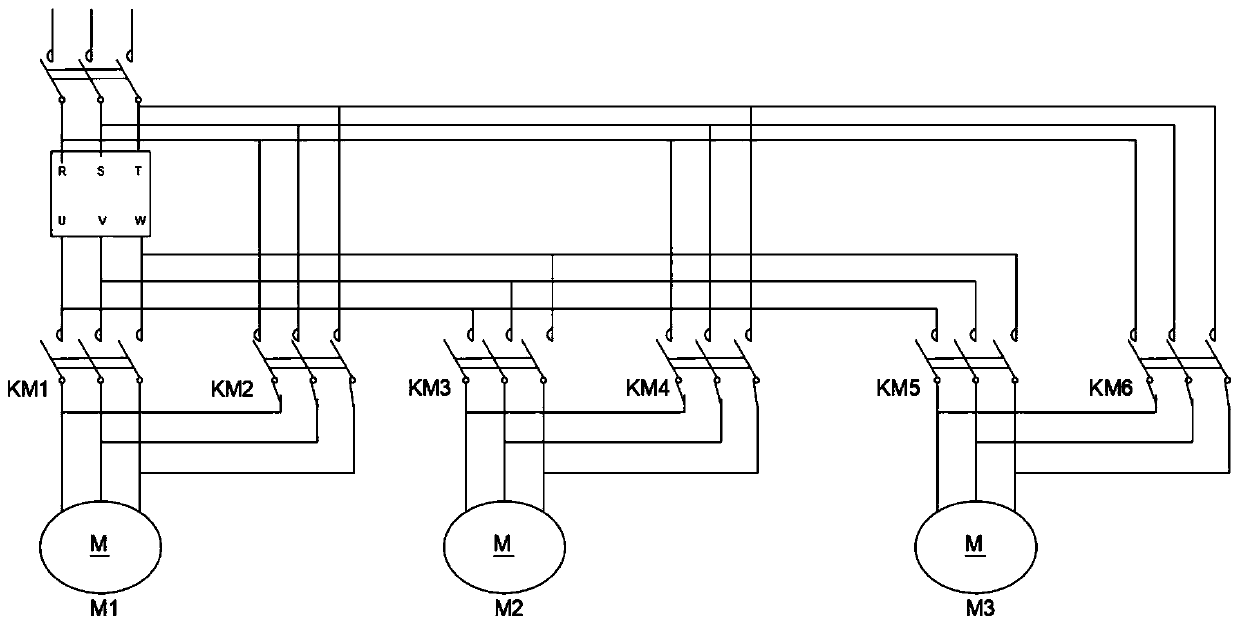

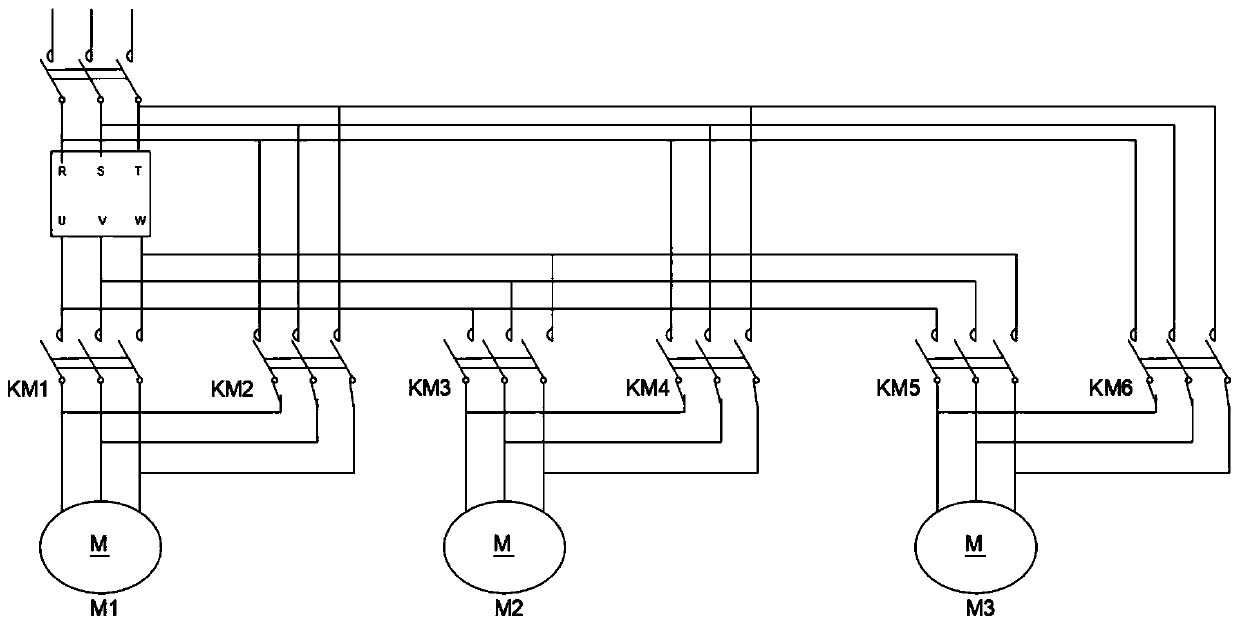

[0021] The invention relates to a method for using PLC to control a frequency converter to start multiple large motors.

[0022] The second step is to limit the step-by-step start of a single motor by the PLC program.

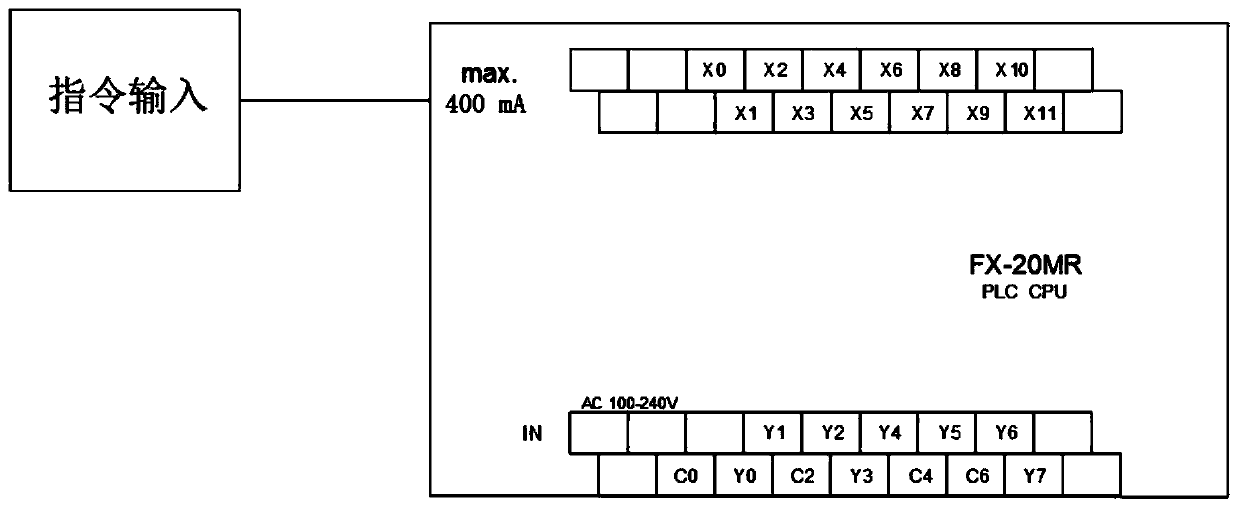

[0023] In the third step, after the PLC receives the start command, the Y1 action starts the KM1, and the Y0 action starts the inverter. When the frequency reaches 50.5HZ, the auxiliary relay of the inverter outputs the passive switch signal. When x0 is turned on, the PLC stops the output of y0 and y1.

[0024] Step 4 After a short delay, Y2 starts KM2, the motor is put into power frequency operation and the start is completed, and the next motor can be put into start.

[0025] Step 5: After the frequency converter stops, the frequency decreases rapidly to zero to prepare for the start of the next motor.

[0026] Button, touch screen and configuration software can be selected for start command input.

[0027] The switch circuit is composed of an air switch an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com