Automatic-displacement visual detection device

A visual detection device and displacement technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve the problems of increased production costs, large manpower and time consumption, and large influence of human factors. , to achieve the effect of reducing production costs and improving the efficiency of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, and the following embodiments do not constitute a limitation of the present invention.

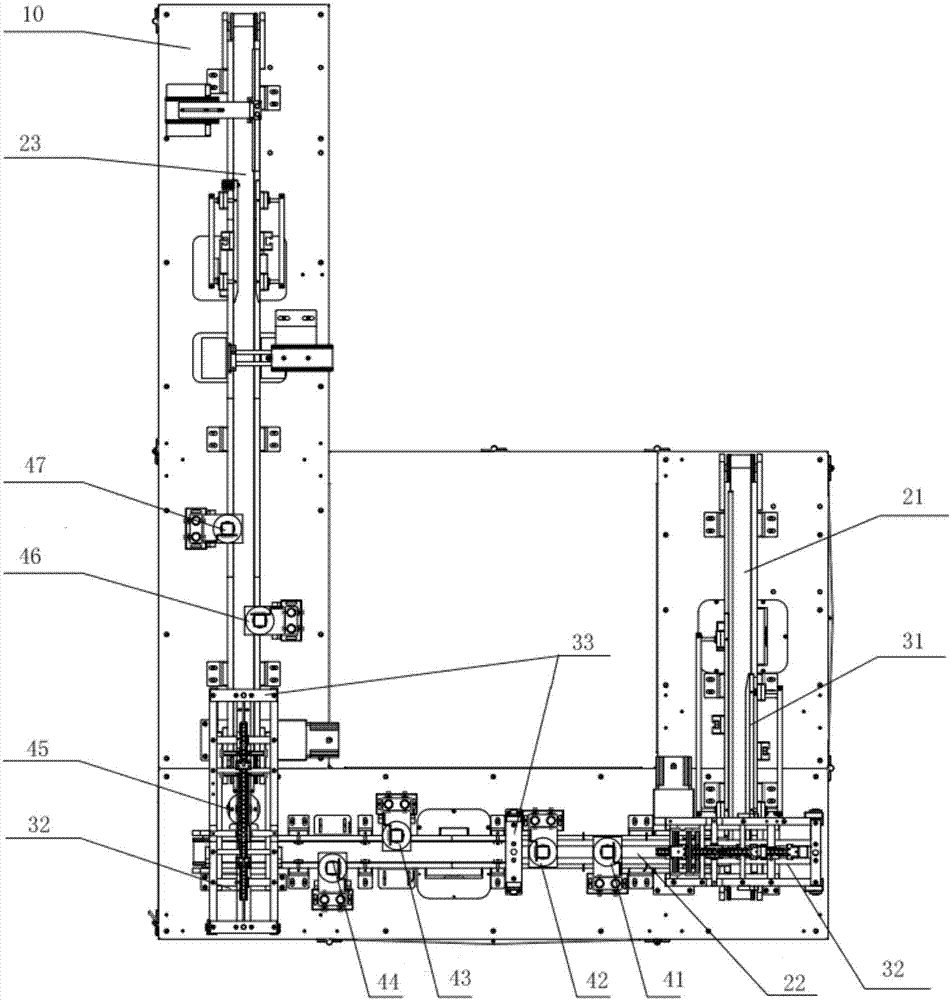

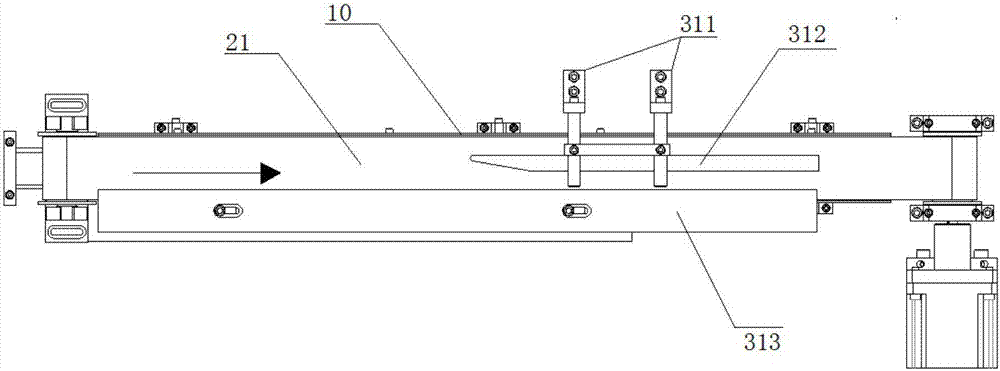

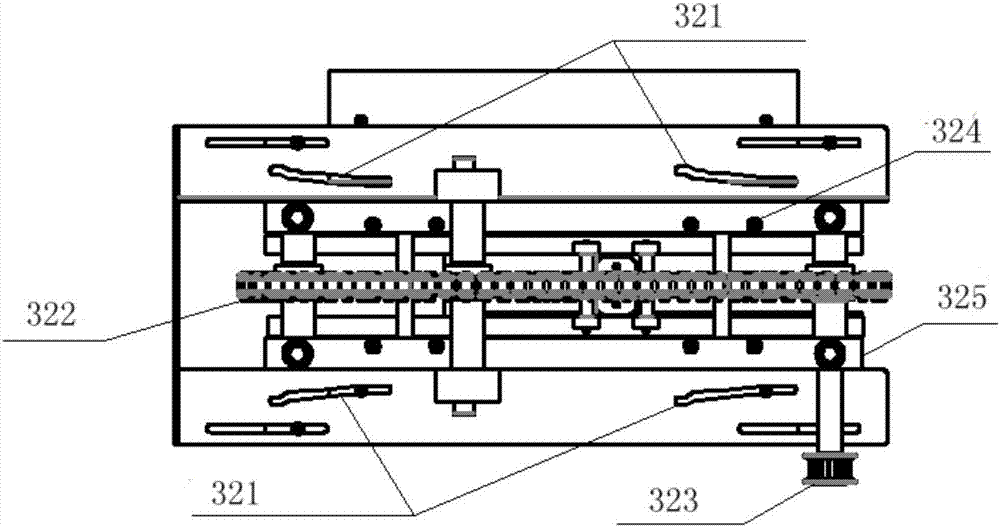

[0019] The invention provides a visual detection device for automatic displacement, figure 1 It is a top view of the device, which is used for automatic detection of detected objects, especially for automatic detection of magnetic materials, and can also be used for detection of other workpieces that need to be inspected for appearance defects. This device comprises frame 10, and described frame 10 is provided with first conveyer 21, second conveyer belt 22 and the 3rd conveyer belt 23, and first conveyer belt 21, second conveyer belt 22, the 3rd conveyer belt 23 are fixed on frame 10 On the working table, the transmission direction of the first conveyor belt 21 is perpendicular to the transmission direction of the second conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com