Zero-sequence current mutual inductance device

A mutual induction device and zero-sequence current technology, which is applied to inductors, transformer/inductor cores, circuits, etc., can solve the problems of zero-sequence current mutual induction devices such as temperature rise, core loss, and power waste, so as to save manpower , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

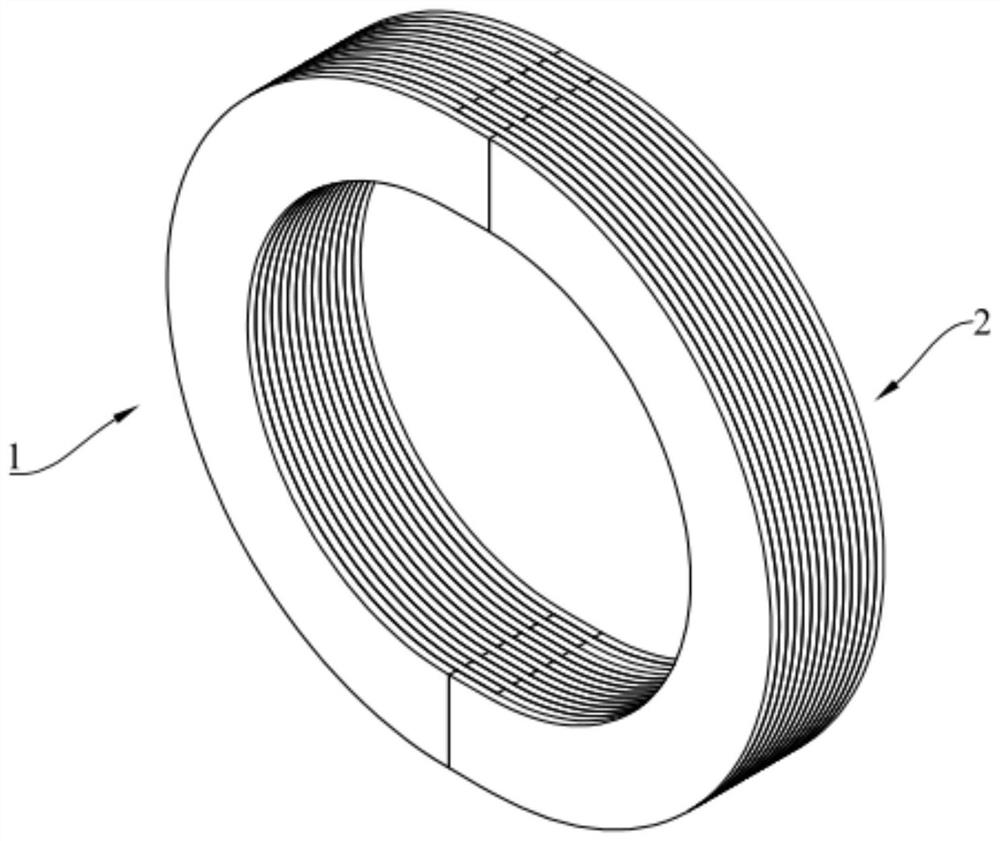

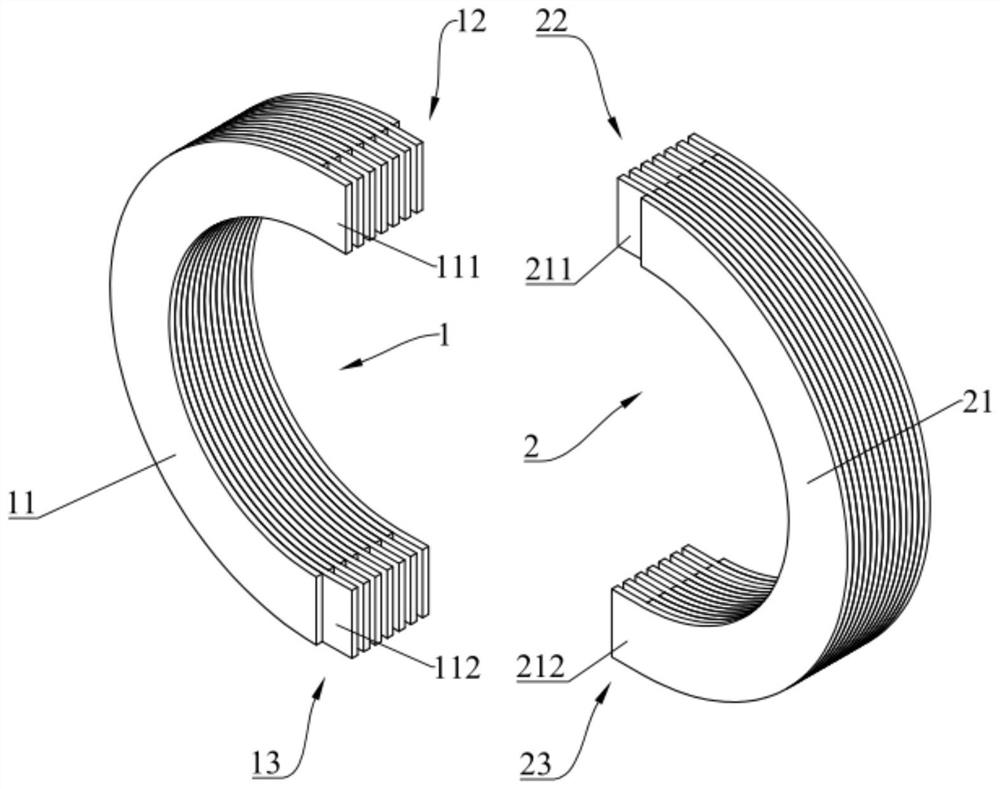

[0038] This embodiment provides a zero-sequence current mutual induction device. Such as Figure 1-Figure 3 As shown, the zero-sequence current mutual induction device includes a first iron core 1 and a second iron core 2, the first iron core 1 is formed by stacking a plurality of first steel sheets 11 insulated from each other, and the second iron core 2 is formed by stacking mutually insulated A plurality of second steel sheets 21 are stacked, and the number of first steel sheets 11 is equal to the number of second steel sheets 21 . The first iron core 1 and the second iron core 2 are detachably connected end to end in order to form a ring structure, and in the ring structure, the first steel sheet 11 and the second steel sheet 21 are in contact one by one, and the size of the ring structure should be It can ensure that three phase wires can pass through at the same time.

[0039] The iron core in the traditional zero-sequence current mutual induction device is a closed ring...

no. 2 example

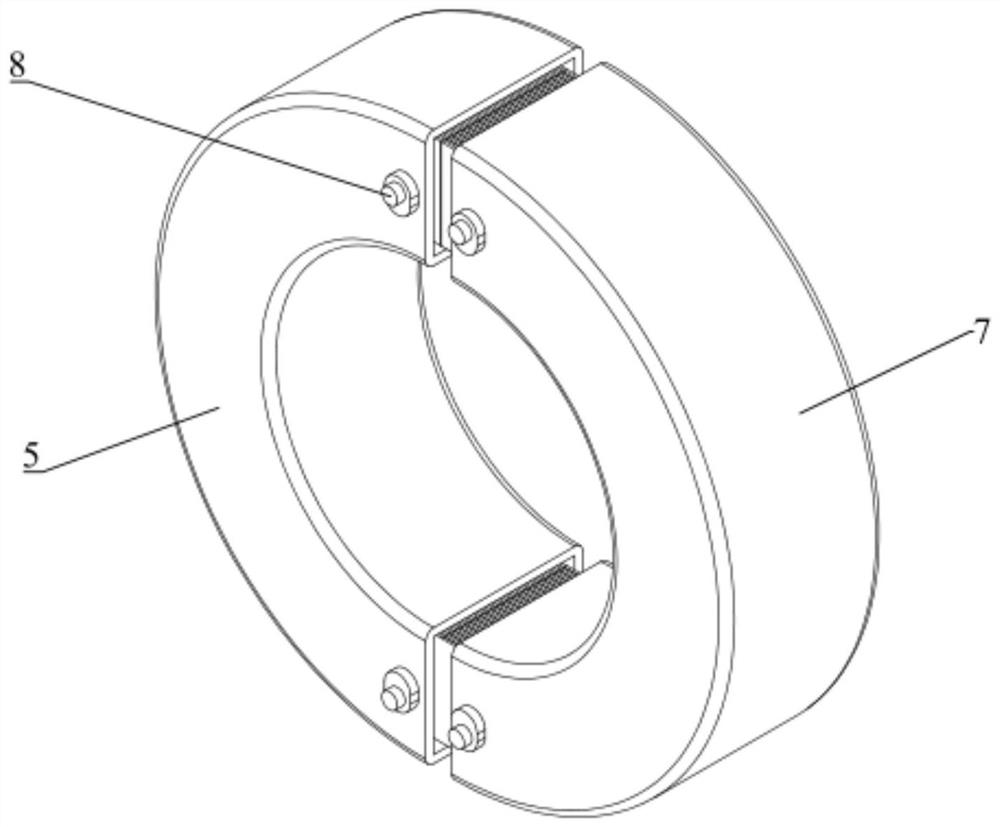

[0060] This embodiment provides a zero-sequence current mutual induction device, which adds locking mechanisms for the first iron core 1 and the second iron core 2 on the basis of the first embodiment.

[0061] Such as Figure 4-Figure 6 As shown, in order to ensure the stability of the entire device after the first iron core 1 and the second iron core 2 are closed to form a ring structure, the zero-sequence current mutual induction device also includes an insulated first bolt 3, a first nut 31, a second bolt 4 and The second nut 41, the first end 111 and the third end 211 are all provided with a concentric first through hole 5, the first bolt 3 passes through the first through hole 5 of the first end 111 and the third end 211 and connects with the first The nut 31 is threaded; the second end 112 and the fourth end 212 are all provided with a concentric second through hole 9, and the second bolt 4 passes through the second through hole 9 of the second end 112 and the fourth en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com