Nickel-chromium alloy sputtering target materials and hot isostatic pressing preparation method thereof

A hot isostatic pressing, nickel-chromium alloy technology, applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc. The target material does not meet the sputtering requirements and other problems, so as to achieve the effect of small grain size and uniform internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

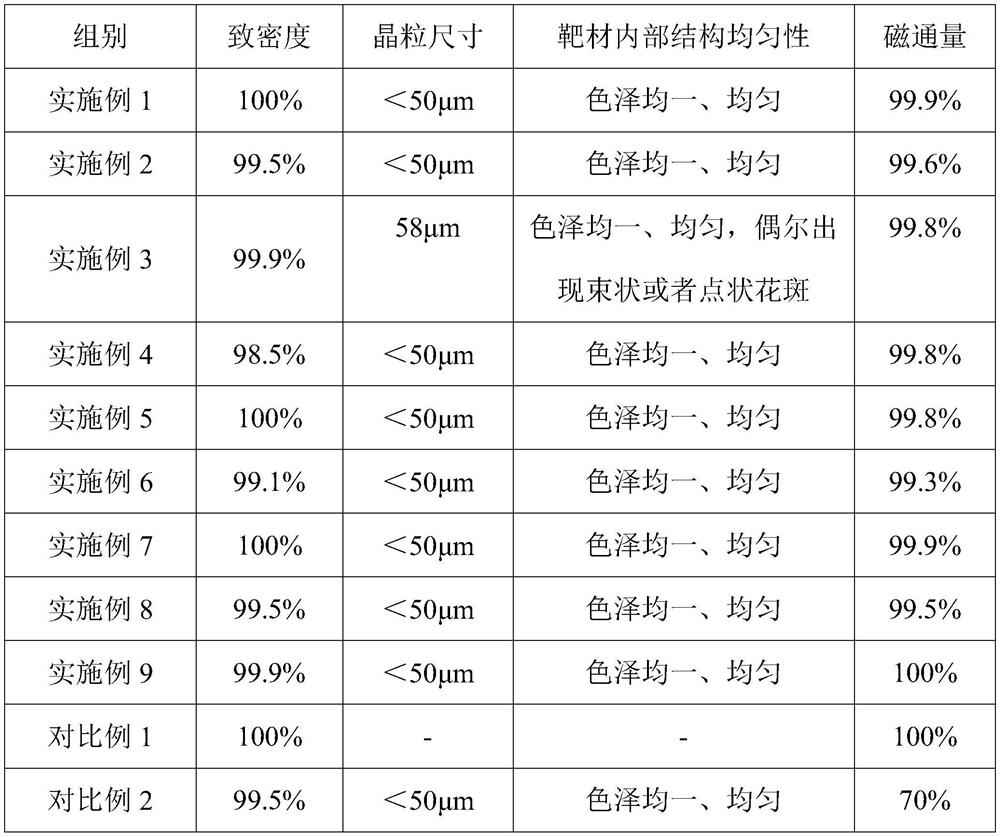

Examples

Embodiment 1

[0057] This embodiment provides a method for preparing a nickel-chromium alloy sputtering target by hot isostatic pressing, and the method for preparing the hot isostatic pressing includes the following steps:

[0058] (1) prepare the nickel-chromium alloy powder that Cr content is 50wt%, pack into stainless steel mould, carry out tamping and sealing successively;

[0059] Wherein, the nickel-chromium alloy powder is obtained by mixing nickel-chromium alloy raw material powder with a Cr content of 20wt% and chromium powder, the average particle size of the nickel-chromium alloy raw material powder is <100 μm, and the average particle size of the chromium powder is <100 μm; Said mixing is carried out in a powder mixer, adopting the mode of adding zirconium balls for dry mixing, controlling the mass ratio of balls corresponding to said zirconium balls to be 3:10, and mixing evenly for 30h under the protection of argon;

[0060] (2) Put the mold sealed in step (1) into a heating ...

Embodiment 2

[0064] This example provides a method for preparing a nickel-chromium alloy sputtering target by hot isostatic pressing, except that the temperature of the hot isostatic pressing treatment in step (3) is replaced by 800 °C from 950 °C, other conditions are the same as in Example 1 exactly the same.

Embodiment 3

[0066] This example provides a method for preparing a nickel-chromium alloy sputtering target by hot isostatic pressing, except that the temperature of the hot isostatic pressing treatment in step (3) is replaced by 1100 °C from 950 °C, other conditions are the same as in Example 1 exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com