Multi-sound-cavity telephone receiver

A receiver and sound cavity technology, applied in the field of multi-sound cavity receivers, can solve problems such as poor low-frequency sound wave characteristics, and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

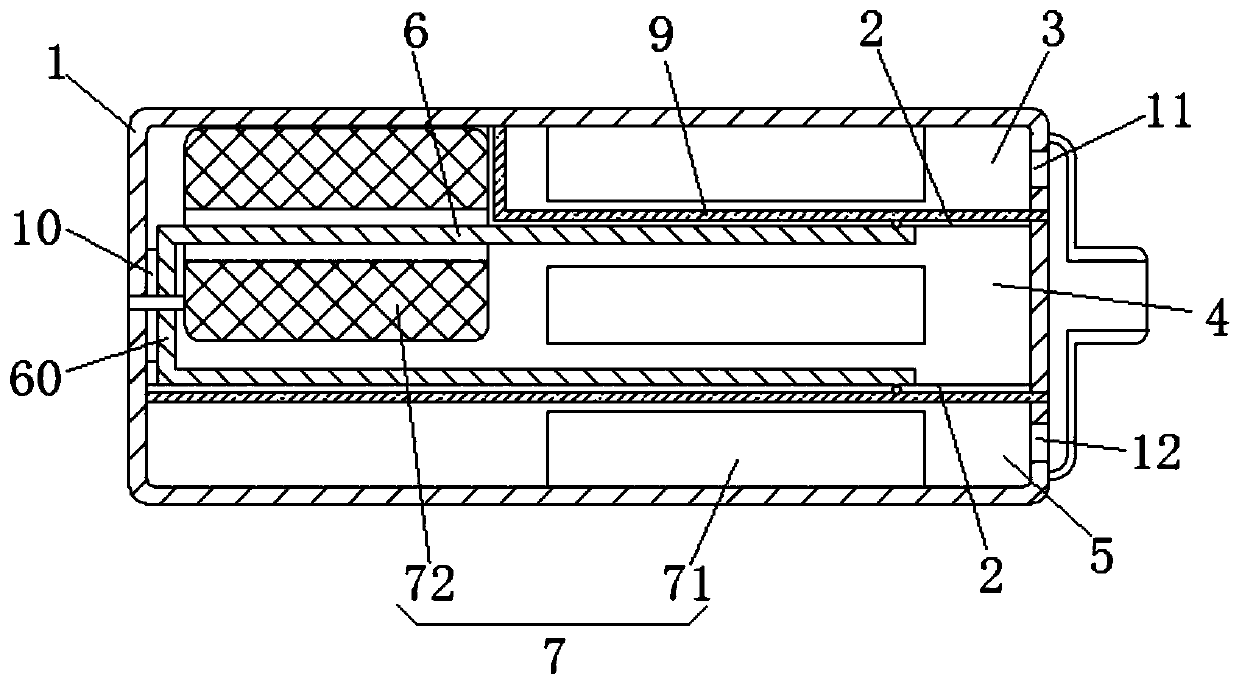

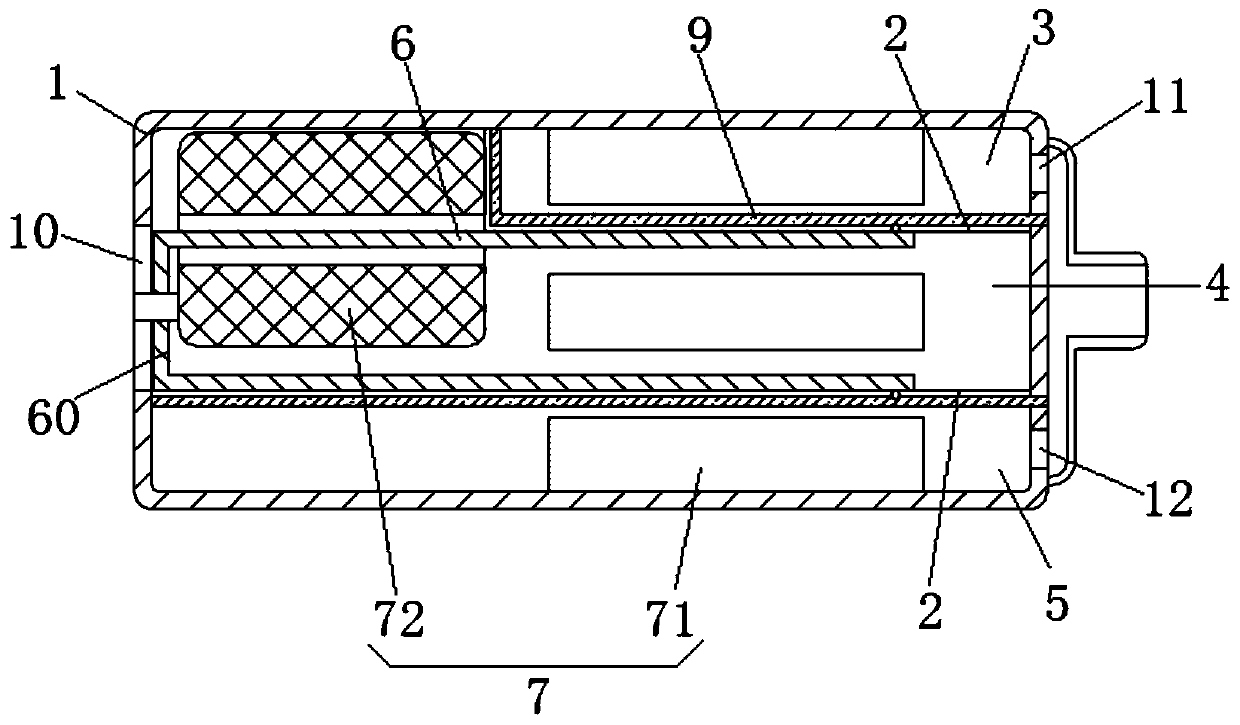

[0048] This embodiment provides a multi-cavity receiver, which includes a housing 1, a sounding membrane mechanism and at least one driving mechanism. Wherein, the pronunciation membrane mechanism comprises at least two pronunciation membranes 2, is installed on the casing 1, as figure 1 As shown, two sounding membranes 2 are set, and the two sounding membranes 2 divide the hollow cavity into a main sound cavity 3, an installation cavity 4 and a secondary sound cavity 5, and the main sound cavity 3, the installation cavity 4 and the secondary sound cavity 5 Arranged side by side, the volumes of the main sound cavity 3 and the secondary sound cavity 5 are not equal, the pronunciation membrane 2 of the main sound cavity 3 is L-shaped, and a support frame 9 is also arranged in the hollow cavity, such as Figure 5As shown, the supporting frame 9 is L-shaped as a whole, and the sounding film 2 of the main sound cavity 3 is bonded and fixed on the wall surface of the supporting fram...

Embodiment 2

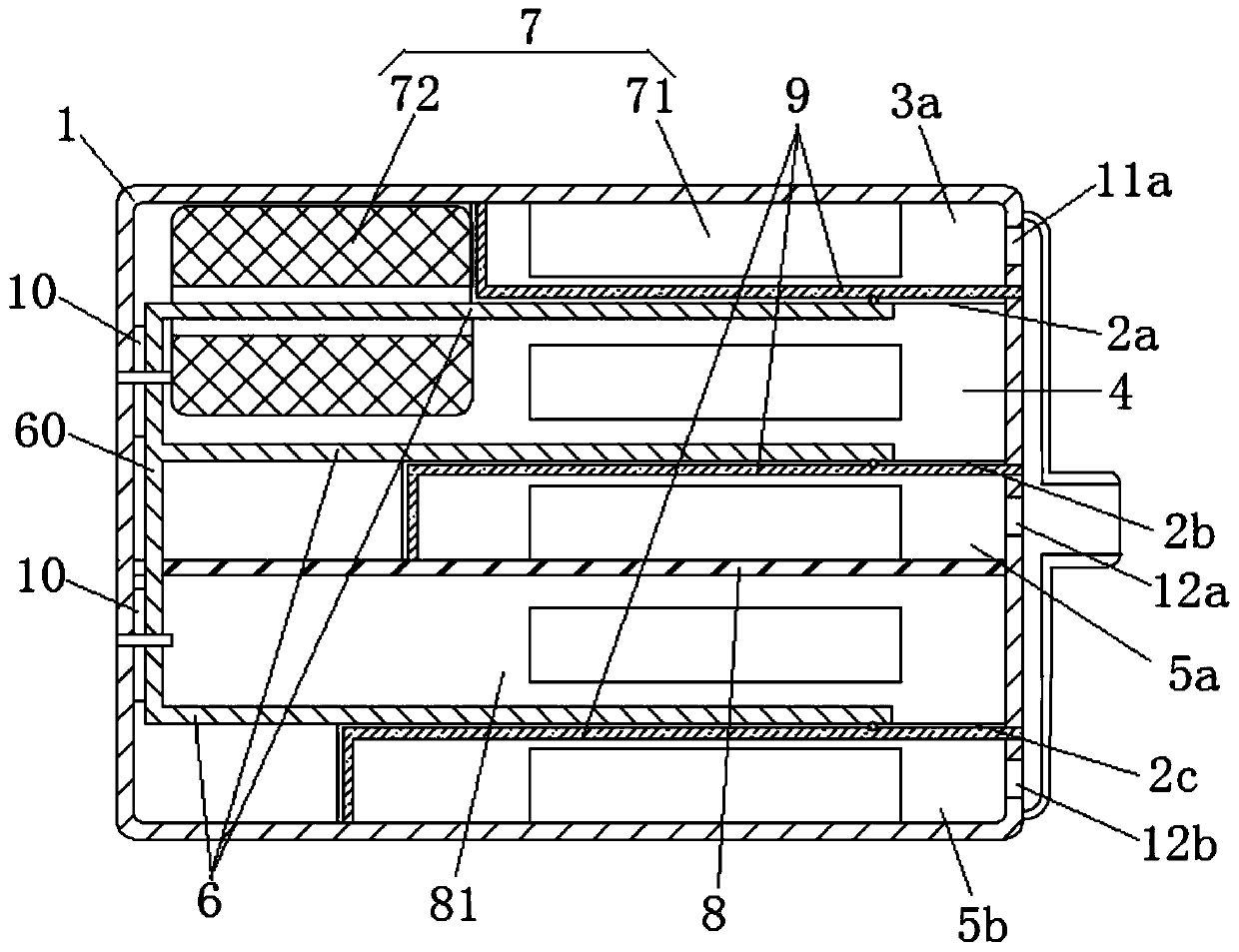

[0057] This embodiment provides a multi-cavity receiver. Compared with the structure of the receiver provided in Embodiment 1, the difference is that at least three sounding membranes 2 are provided, and at least three corresponding vibrating parts 6 are provided, such as figure 2 As shown, in the present embodiment, three sounding membranes 2 are provided, and the first sounding membrane 2a, the second sounding membrane 2b and the third sounding membrane 2c divide the hollow cavity into the first sound cavity 3a and the installation cavity arranged side by side in sequence. 4. The second sound cavity 5a, the isolation cavity 81 and the third sound cavity 5b, the first sound membrane 2a, the second sound membrane 2b and the third sound membrane 2c are respectively fixed on the support frame 9 located in the installation cavity 4 or the isolation cavity 81 on the wall and cover the inner cavity of the support frame 9, such as Figure 5 As shown, the support frame 9 has an L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com