Printer with built-in hob paper cutting device

A paper cutting device, built-in technology, applied in the printing device, printing, etc., can solve the problems of blade wear, reduce the service life of the paper cutting device, increase the height or length, etc., to prolong the service life, increase the service life, reduce the The effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

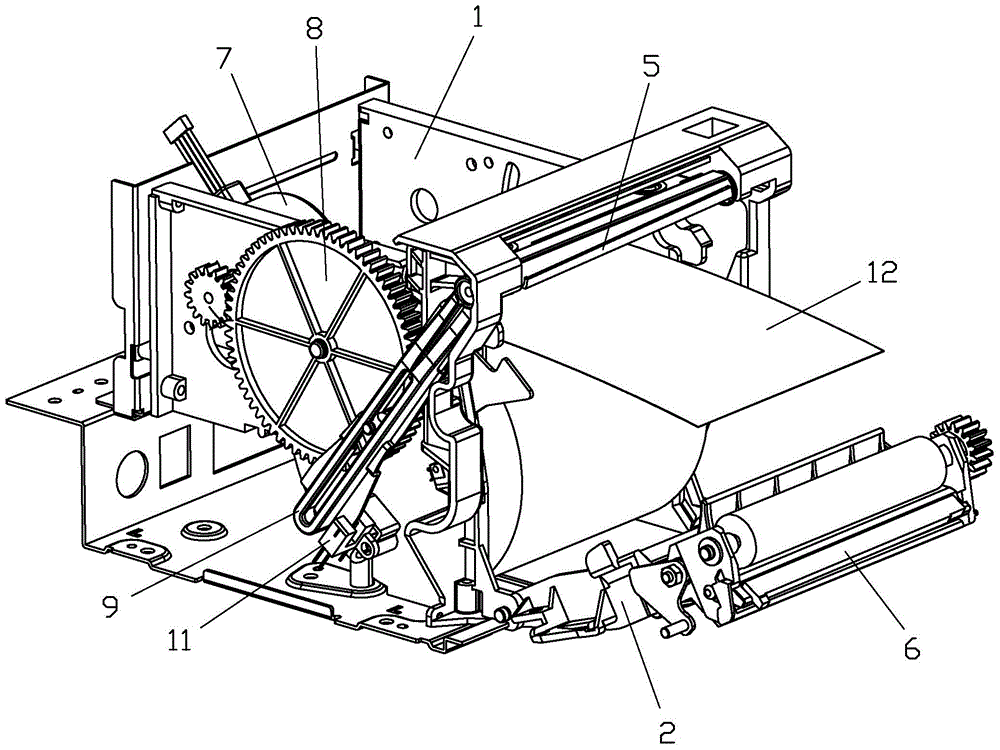

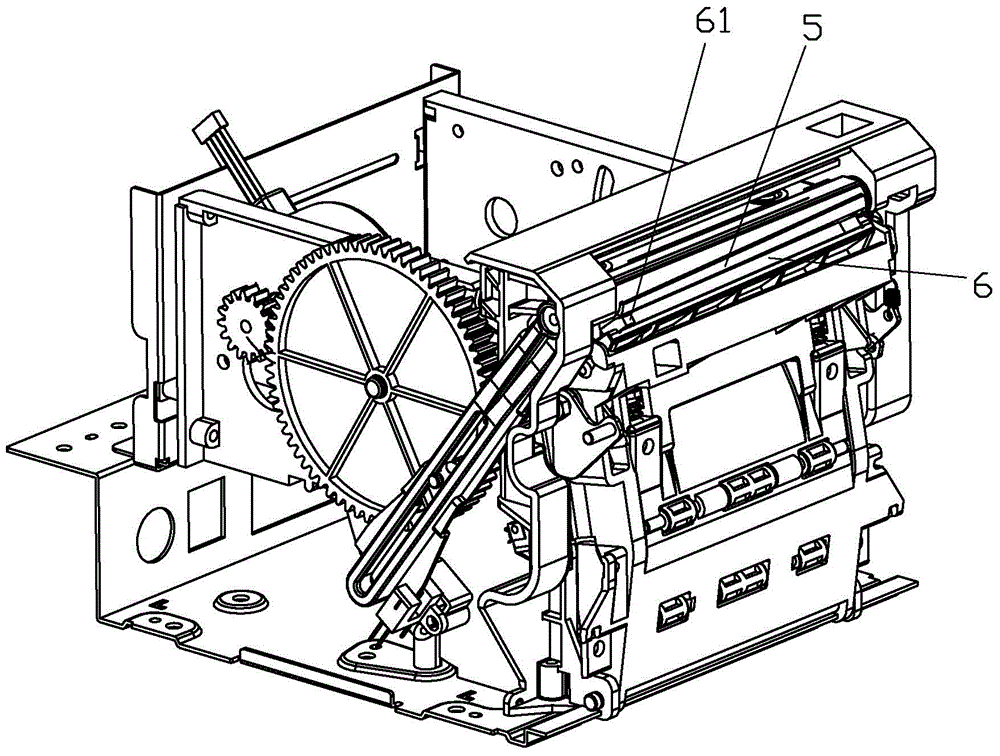

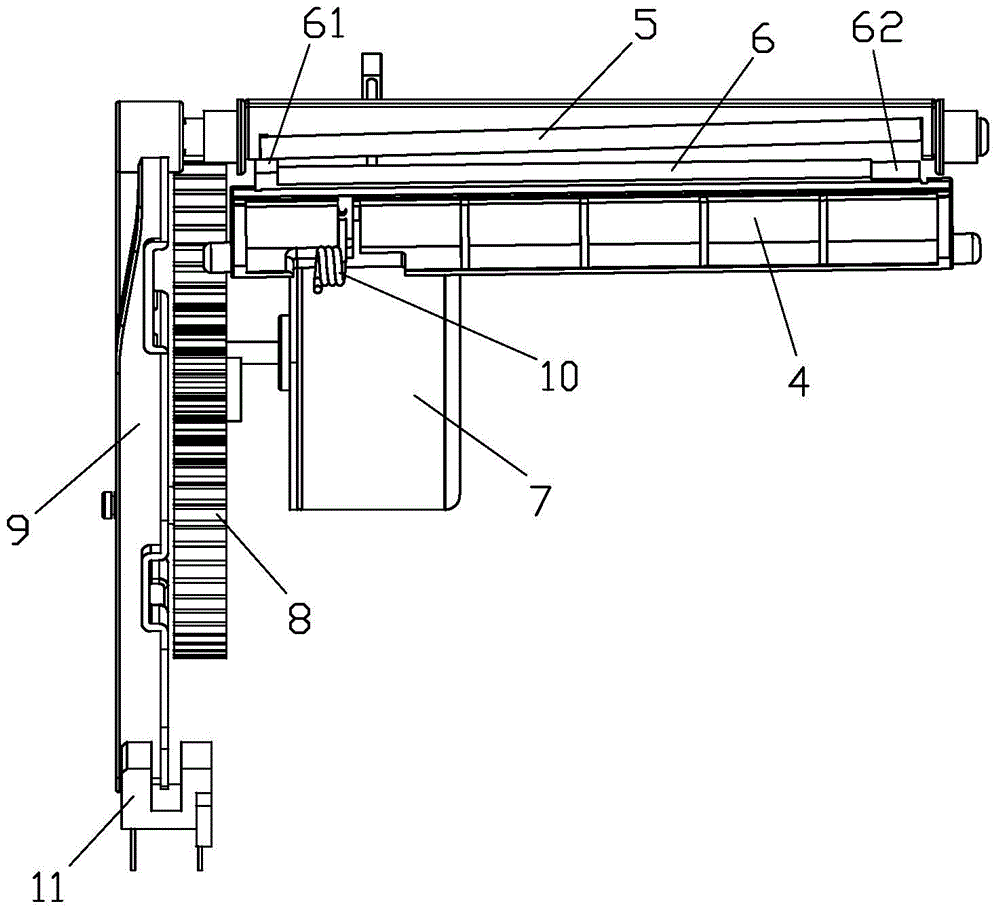

[0027] refer to Figure 1~Figure 11 , the printer with the built-in roller cutting device of the present invention includes a core assembly 1 and a paper-feeding roller fixing frame assembly 2 connected to the core assembly 1, and the core assembly 1 and the paper-feeding roller fixing frame The component 2 is pivotally connected with a moving knife fixing frame 3 and a fixed knife fixing frame 4 respectively, and the moving knife fixing frame 3 and the fixed knife fixing frame 4 are provided with a moving blade 5 and a fixed blade 6 respectively. A drive motor 7 and a cutter gear 8 driven by the drive motor 7 are arranged on the top, and a cutter drive arm 9 that is driven by the cutter gear 8 and can swing back and forth is connected to the cutter gear 8. In this embodiment, the following Structure: A rivet 81 is provided on the side end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com