Mechanical overload protection device, speed reduction mechanism and electrically-driven flip driver

An overload protection and mechanical technology, which is applied in the direction of electromechanical devices, mechanical equipment, electric components, etc., can solve the problems of easy damage of electronic components, failure of normal use again, and increase of device torque, so as to achieve smooth installation, save the number of uses and Types, effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

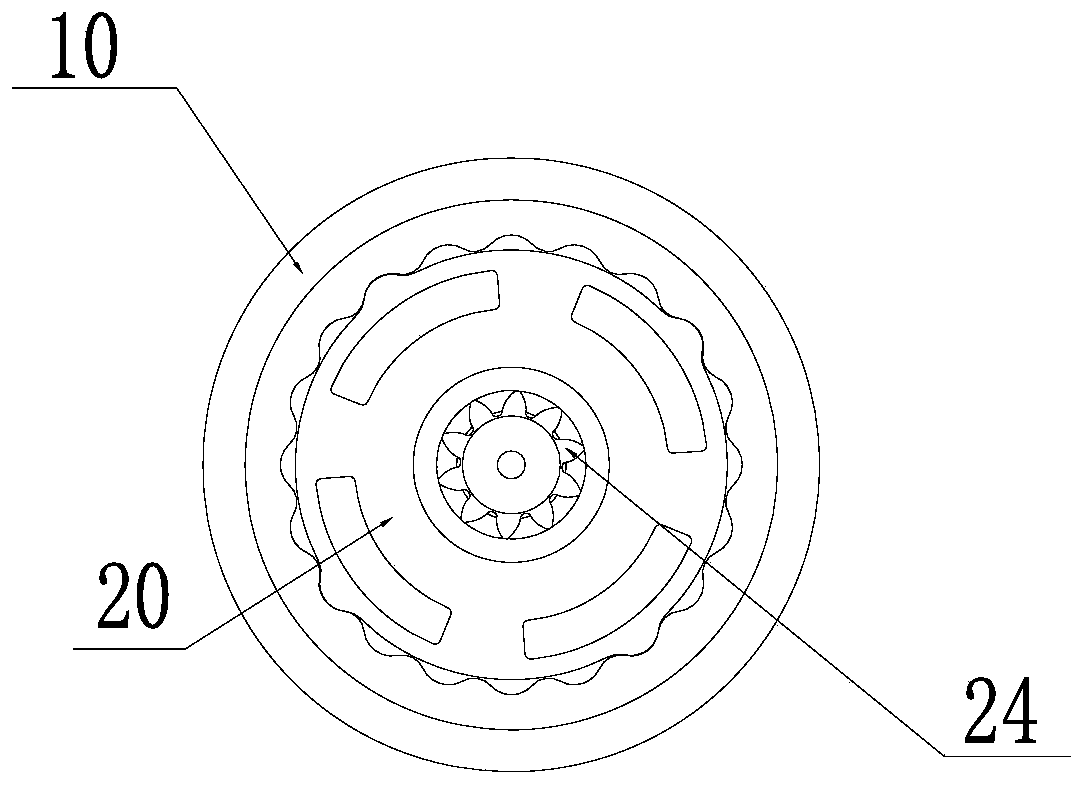

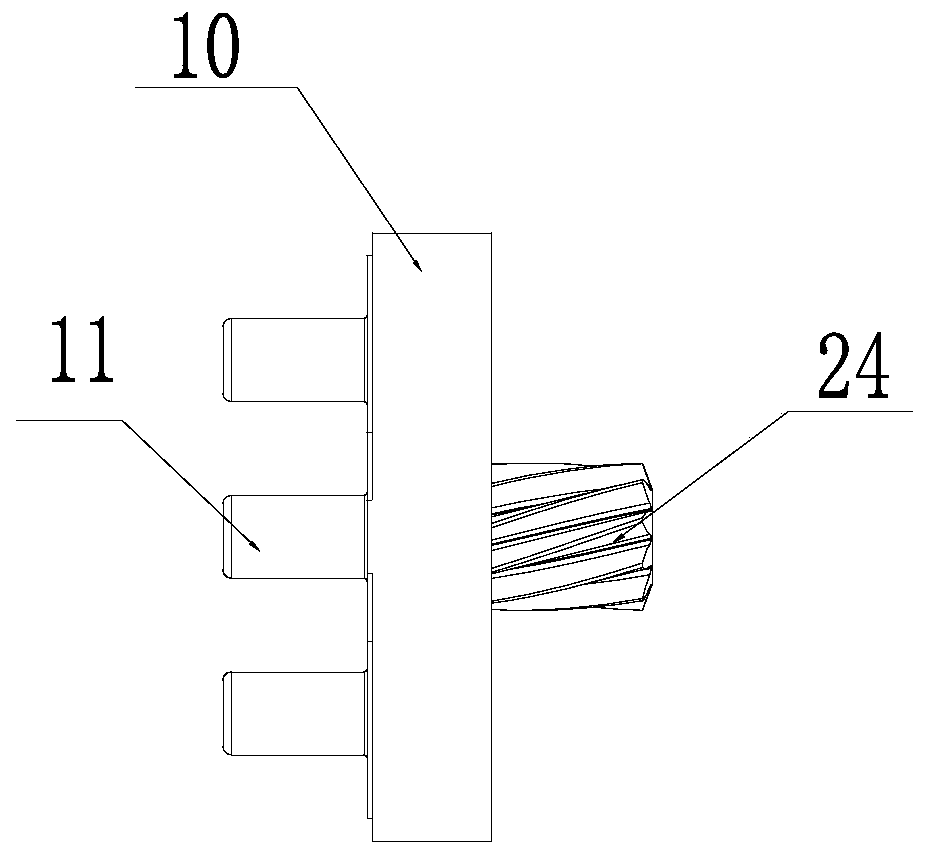

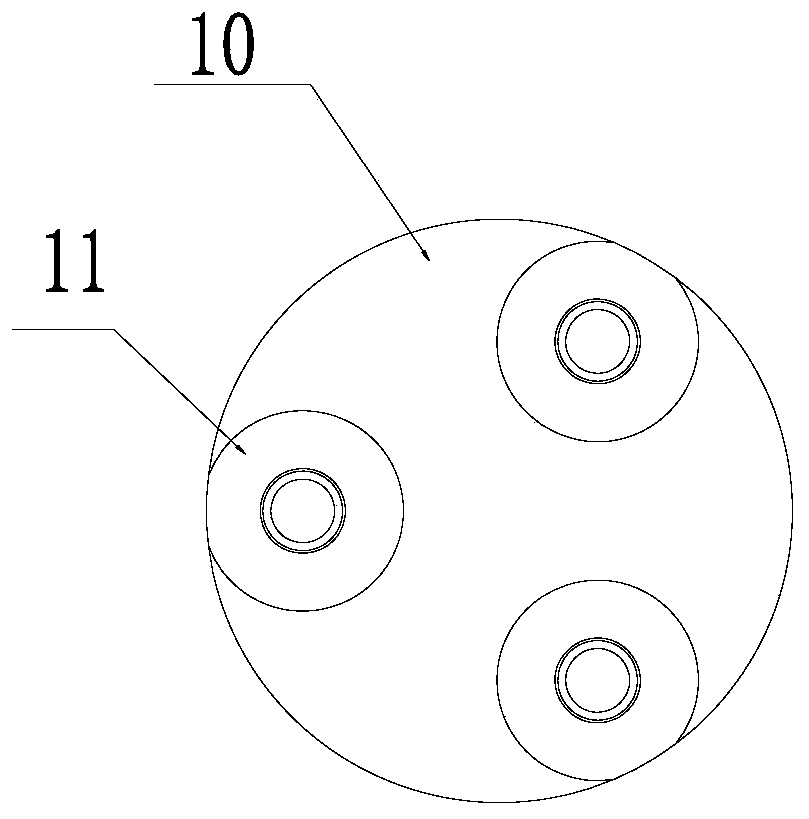

[0027] In order to solve the problem of motor burnout caused by overload of the existing smart home electric drive flip driver, reduce the probability of fire caused by motor burnout, and improve the safety of product use; the invention provides a small volume, large output torque , a mechanical overload protection device with compact structure, low friction, low noise, stable operation and long service life. In order to further illustrate the technical solution of the present invention, the following will be described in detail in conjunction with the relevant drawings.

[0028] see Figures 1 to 5 : A kind of mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com